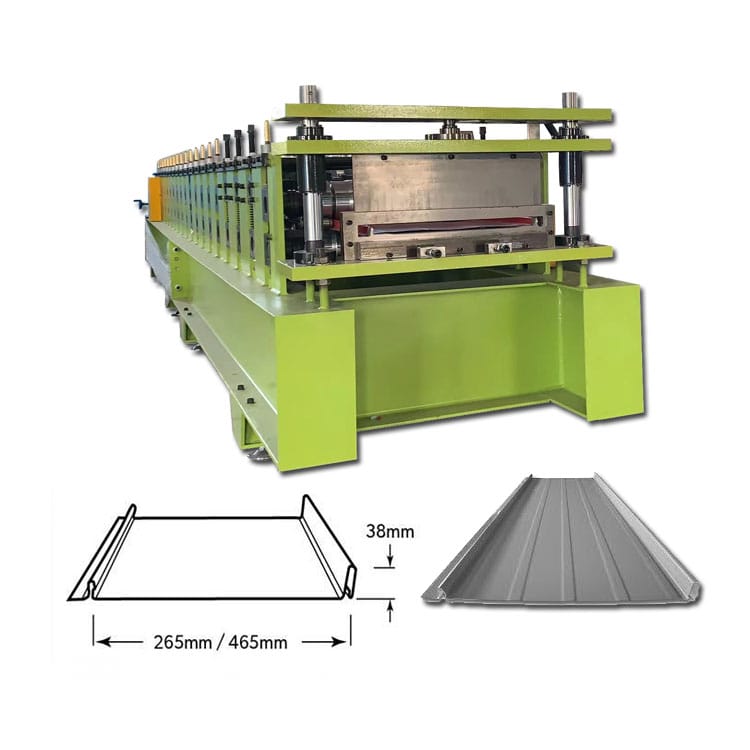

Snap lock roof panel machine standing seam roof

NO.4 ROAD, ECONOMIC DEVELOP ZONE, BOTOU CONUTY, CANGZHOU CITY, CHINA

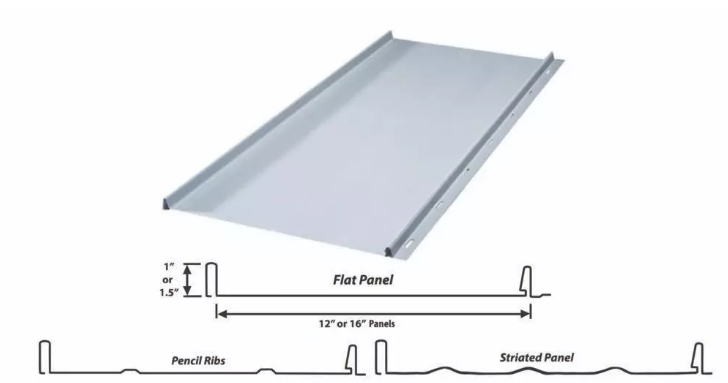

Metal roofing panels have been a workhorse in the construction industry since the turn of the century. Initially, small pieces of copper and zinc were hand formed by craftsman. The slow and manual process created beautiful but often price prohibitive roofs.Over time, rolling manufacturing lines were introduced. This mechanization enabled a quicker and more efficient production and install process as roll formed sheets routinely covered a 3' wide section of the roof with one panel running from eave to ridge.

There Some Profile drawings Reference :

Description:

Metal roofing offers a fairly long list of benefits. When compared to traditional single roofs, they are hands-down more durable. Metal roofs can last up to 50 or 60 years, while a shingle roof will need to be replaced in about half of that time. And when it is time to replace them, the metal panels are recyclable, which contributes less material to landfills.

Configuration

1. For the feeding part, we use the roller design to protect the surface of the coil.

2. For the transmission, we use the double chain.

3. For the base frame, we use the strong with more supporting to make sure the machine working more steady.

4. For the main motor we use Siemens, if you need we can customize according to your needs.