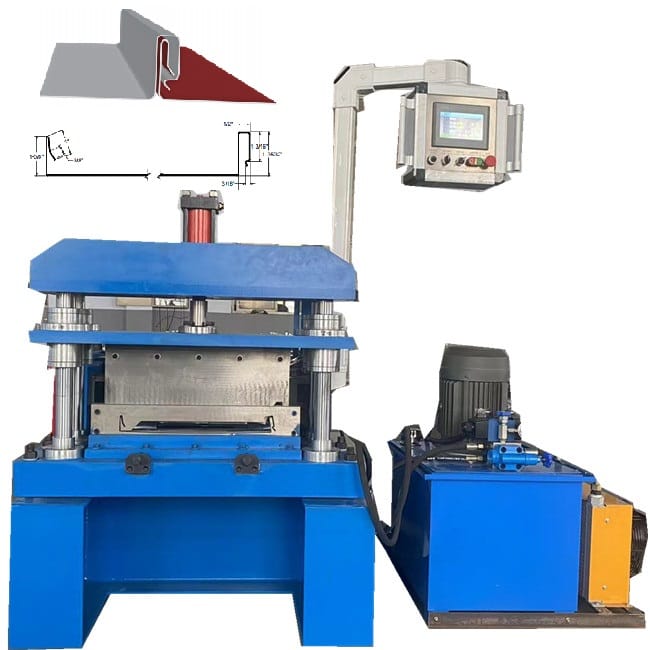

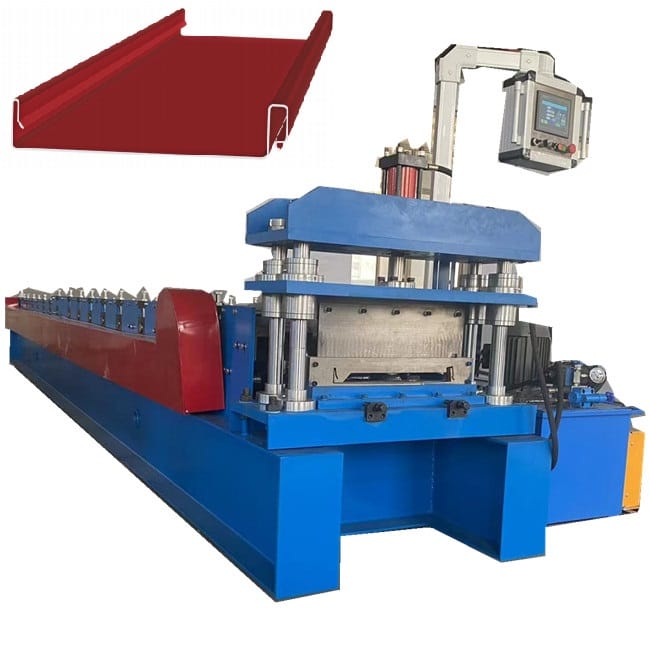

1.75”SnapLock Standing Seam Roofing Sheet Rolling Forming Machine for USA

Snap Lock Standing Seam Roofing Sheet Rolling Forming Machine is designed to make the standing seam in batch fully automatically.

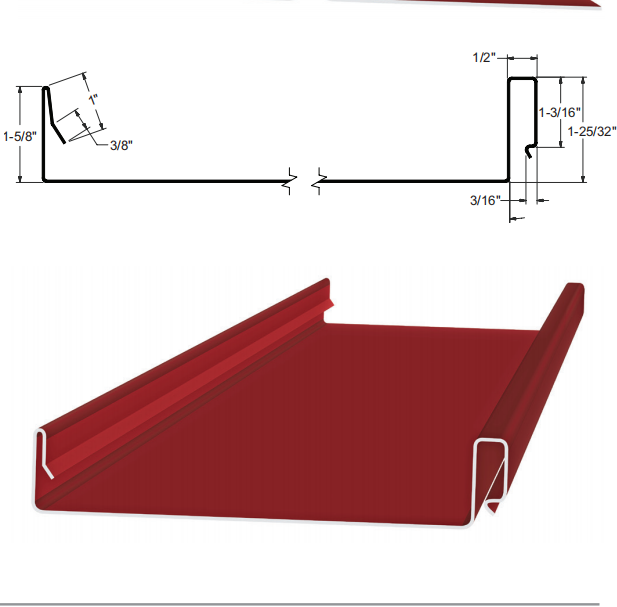

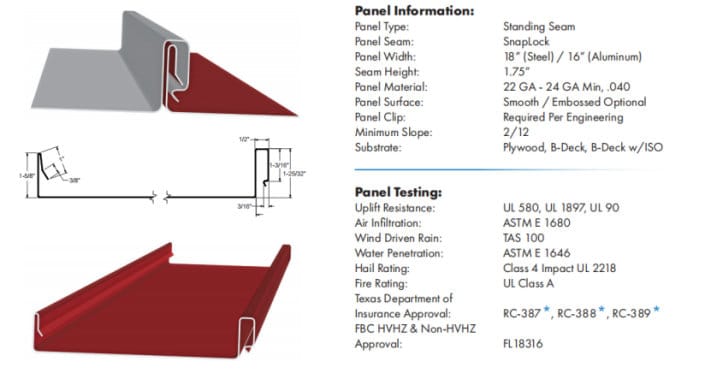

1.75” SnapLock Standing Seam Information:

Panel Notes:

• With this panel engineering, you may opt to use heavier gauge coil and narrower width panels. Clip spacing will not change.

• For slopes lower than a 2/12 roof pitch. Technical Department for further installation requirements.

• This panel uses a 24” coil (Steel) / 22” coil (Aluminum).

• This panel uses 6-1/8” of material to form the panel.

• If you take the square footage of the roof and multiply that by 1.34, the total will be the amount of coil needed to manufacture the panels.

• Clip Relief, Bead Ribs, Striations, and Pencil Ribs do not affect the engineering or function.

• This panel is approved for Weather tight Warranties.

* Available in steel only

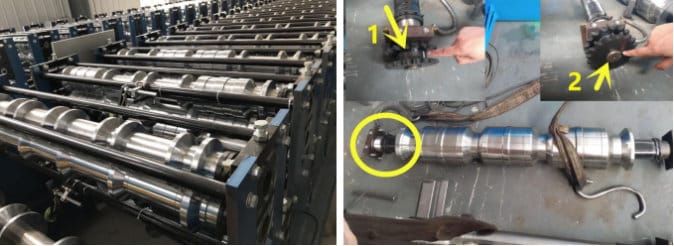

1.75”SnapLock Standing Seam Roofing Sheet Rolling Forming Machine

Rolling shaft Roller | Shaft material:45# STEEL |

Shaft diameter: 75 mm | |

Tempering treatment to prevent deformed and improve hardness | |

45# steel | |

Chromed treatment, improve the hardness and prevent abrasion, anti corrosion increase of service life | |

Rolling station | 16 rolling stations |

Work speed | 20 m/min |

Machine structure | Steel plate welded structure |

Machine basic frame | 350# H steel welded |

Work power | 5.5 kw |

Rolling spacer | Anti rusty treatment |

Pull rod | Anti rusty treatment |

Transmission | By Chains with cover |

Noted: please fill the lube in case the chains getting dry |

About the rollers:

Advantage: We make grooves to inset two nuts and cushion on the shaft. To avoid shafts loosing when machine works. Due to this design, shafts will be fixed more and more firm when it is working.

Control station with aviation plug

1.75”SnapLock Standing Seam Roofing Sheet Application:

1.75”SnapLock Standing Seam Roofing Sheet Rolling Forming Machine working video for your reference: