Double layer machine for Slovenia motor shearing or hydraulic shearing

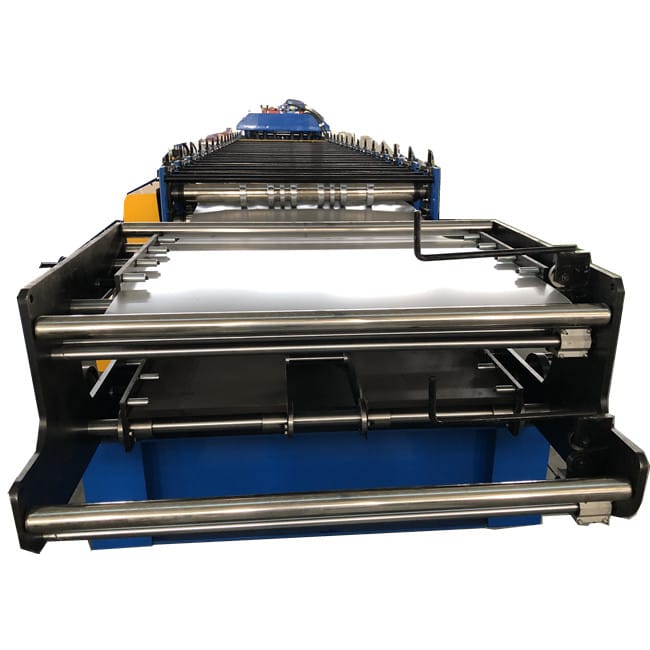

Double layer machine for Slovenia motor shearing or hydraulic shearing fully automatic type. Double later machine, we also called it double layer metal roofing sheet rolling forming machine, which it is a kind of rolling forming machine. By double layer it can save cost of machine production, save space, but it can not do the production at the same time and a little hard to do the routine maintenance. Here we take the machines we made for Slovenia to show it how the double layer machine designed.

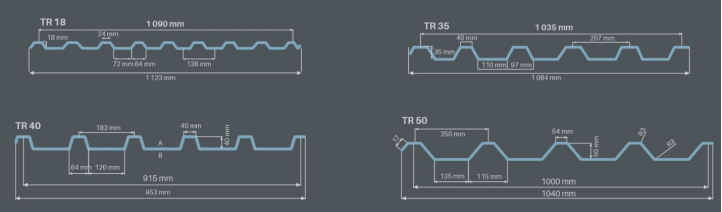

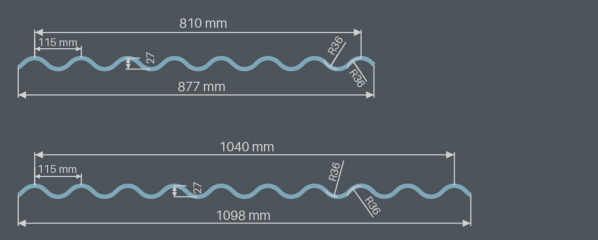

Double layer machine drawing profile:

As to the drawing profile, we can fully designed according to customer requirements. Here are some popular drawing profile in Slovenia for your reference:

We call it as Tr18, Tr35, Tr40, Tr50, those are for IBR type or trapezoidal type. And the input coil width normally using 1250mm, and the thickness range from 0.4 to 0.8mm.

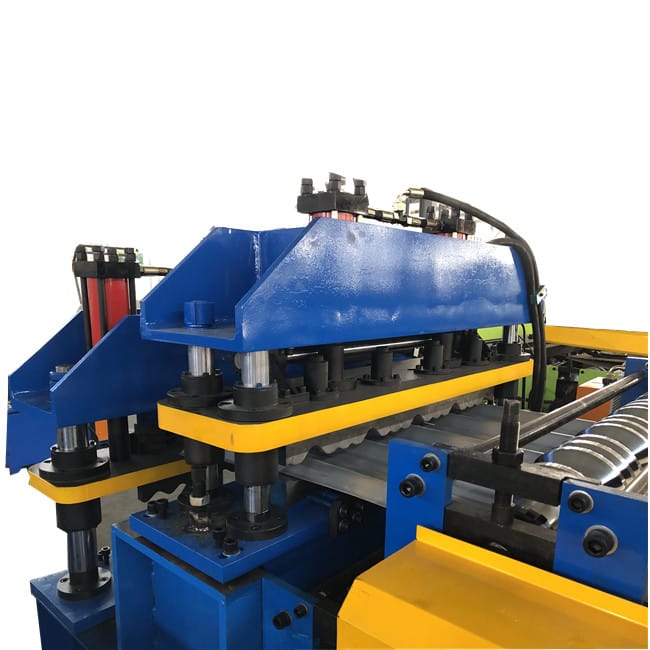

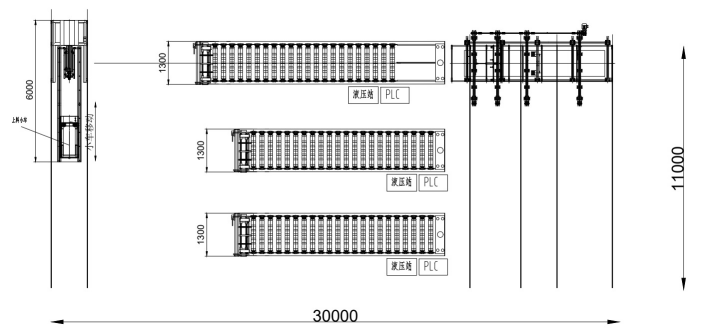

Double layer machine for Slovenia machine design:

Double layer machine working flow:

Main parameter:

Machine frame

| 350mm H beam structure, with 18mm welded steel middle support plate. |

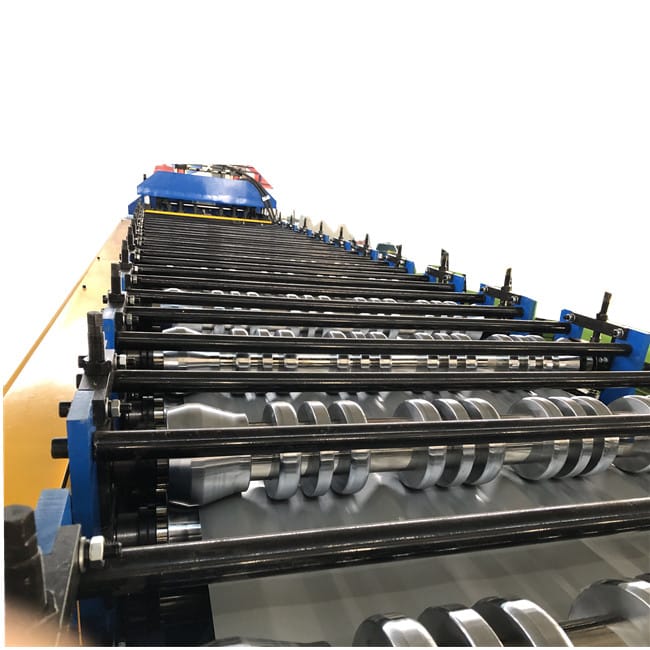

Material of rollers

| High grade 45# forged steel |

Chromed treatment (Chrome thickness:0.05 mm), make the rollers surface more smoothly, improve the hardness and prevent abrasion, anti corrosion increase of service life | |

Forming stations

| Upper layer 20 rows, Lower layer 23 rows |

Rolling type: separate rolling design concept, it can release internal stress from the sheets, then the sheet will be in good shape and high precision. | |

Diameter of shafts | Φ80mm solid |

Material of shafts | High grade 45#,with heat treatment |

Forming speed | 0-15m/min |

voltage | 380V/50HZ/3P (as requested) |

Transmission way | By 1 inch chain (double chains) |

Main motor | 7.5 KW |

Cutting blade material | Gcr12 quenched treatment |

Cutting type | hydraulic post cutting |

Driving method | By pillar type Cylinder |

As to the other elements:

1. The decoiler, you can choose to use the manual one or hydraulic one. For the hydraulic decoiler fully automatic type we have one popular recommendation, with loading car as whole and with rail. By this way, it is movable and it could be used together with other metal roof rolling forming machine. As to the rail length, we can design according to your real requirements.

1. Additional $1000 configuration with track:

2. Not only did it add tracks, but also wheels, motors, and control systems

3. The meaning of a track:

4. Multiple machines can share one hydraulic uncoiler

5. Attention Required:

6. Due to the addition of tracks, the car and the uncoiler share a common frame, which means that the car is closer to the axis leaving the coiler in height. It is necessary to verify the specifications of the customer's steel coils.

This is the normal design separated type. And as to the decoiler, there are following elements optional.

Pressure arm:

If the thickness of the steel coil is thick, it is best to add a pressure arm,Prevent the steel coil from bouncing open

Support table:

If the weight of the steel coil is too large, a support wall can be added to support it to avoid unilateral stress.

Now come to the stacker, we have 6 meters, 9 meters and 12 meters optional. And for the stacker, we also could design with rail, by this way and then you can use it for many metal roofing sheet machines.

And the stacker, we have the following design either for the double layer stacker or single layer stacker.

The biggest difference: The main difference is that the feeding height can be adjusted, and the screw can be adjusted up and down through the motor drive.