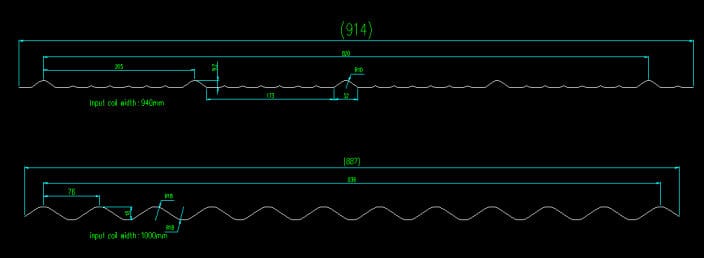

Double layer roofing sheet machine for Chile is designed based on the popular drawings in Chile. The input coil width could be 1000mm and 940mm or others adjustable. We can design them either into single layer normal speed or high speed.

Or design it as double layer roofing sheet machine. Here is one drawing profile for your reference.

Double layer roofing sheet machine for Chile

1.As default you can choose the manual decoiler or automatic hydraulic decoiler.

2. And the manual cutter we will give default but for the hydraulic cut to length we can make according to your requirements.

3. Two pillar pole shearing for long time to use and more durable.

Advantage of Leveling :

With several support rollers, to feed the material more smoothly

Equipped with 2 plastic bands in the middle of the platform and two pinch plates to feed the material, prevent the material surface from being damaged, and feed the material more easily and quickly

With hand wheels to adjust the feeding size, more conveniently.

Up layer and down layer with manual cutter to cut feed material more easily.

Upper layer and down layer with two gears on the outside, so that the upper axis of each layer runs passively to actively, with more power and faster.

Rolling shaft | Shaft material:45# STEEL |

Shaft diameter: 70 mm | |

Tempering treatment to prevent deformed and improve hardness | |

Roller | 45# steel |

Chromed treatment, improve the hardness and prevent abrasion, anti corrosion increase service life | |

Rolling station | Up layer: 17 rolling stations; Down layer: 22 rolling stations |

Work speed | 0-20 m/min |

Machine structure | Steel plate welded structure |

Machine basic frame | 500# H steel welded |

Work power | 5.5 kw |

Rolling spacer | Anti rusty treatment |

Pull rod | Anti rusty treatment |

Transmission | By Chains with cover |

Noted: please fill the lube in case the chains getting dry |

Work type | Hydraulic cutting |

Driving method | By pillar type cylinder |

Cutting device structure | Guide pillar type |

Noted: please fill the lube before start the machine the first time | |

Hydraulic motor power | 5.5 kw |

Hydraulic oil | Hydraulic oil number: 46# |

Quantity: around 100 Litre | |

Maintain: change the hydraulic oil every 2 years | |

Cutter material | GB-Cr12 with heat treatment |

Cutting length tolerance | ±1mm/3m |

Cutting feature | Steady and safe working condition |

Oil tube and wires connection | All the tubes and wires will be marked by the numbers or letters,So it will be very easy to connect for the unprofessional client. |

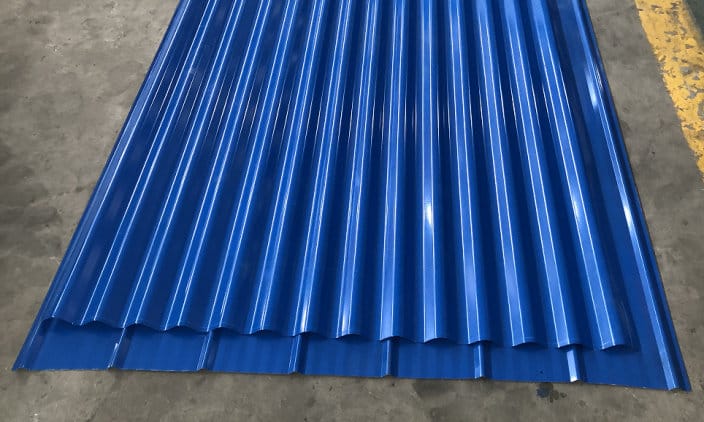

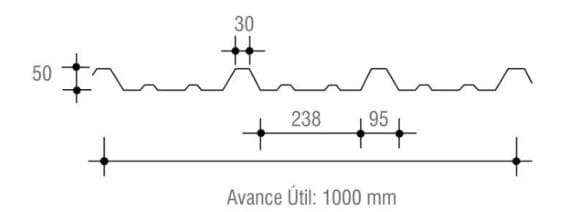

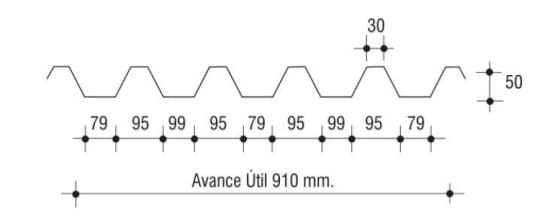

Here are more types popular drawing profile in Chile for your reference:

PV4 Metal Roofing SHEET drawing profile:

PV6 SHEET:

We can fully design double layer machine type according to your requirements. Here is one double layer machine working videos for your reference: