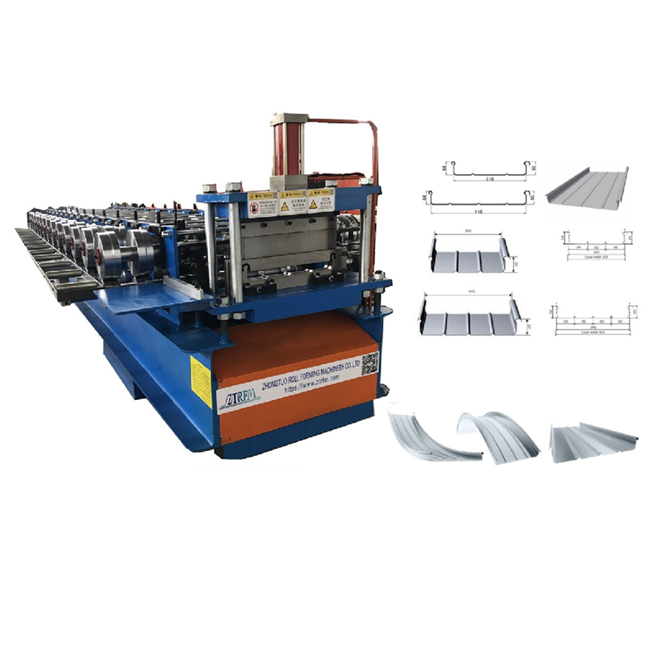

Metal standing seam roof panels machine with slitting and bending machine

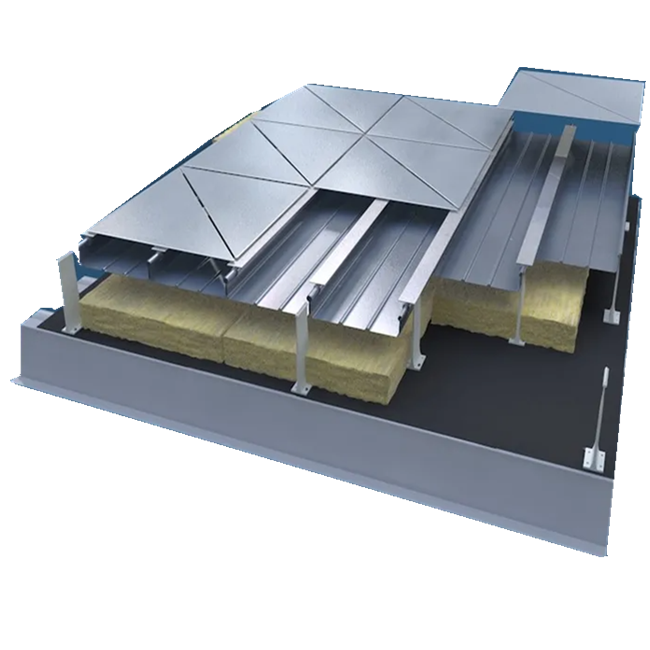

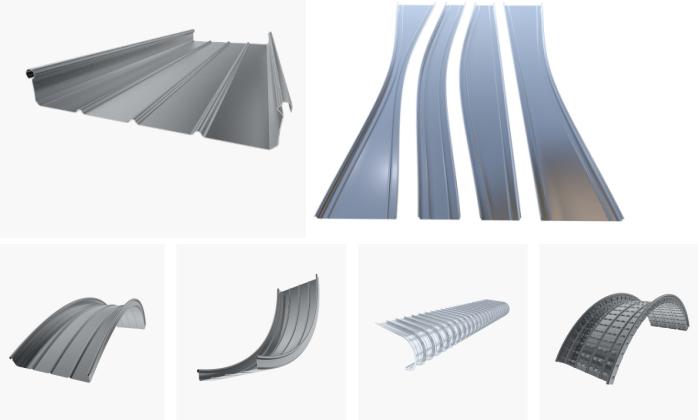

The BEMO roof panel system provides the most advanced and versatile structural standing seam roofing system available in today’s architecturally demanding market. These systems offer the highest wind uplift ratings with the greatest flexibility of any structural standing seam panel in the world. With its bold lines and its ability to be smoothly convex, concave or serpentine curved, this roof panel system offers years of low-maintenance service combined with high visual-impact applications.

Zhongtuo Metal standing seam roof panels machine with slitting and bending machine is designed for making Bemo roof panel system in batch fully automatically. It designed with adjustable width rollers and design, side roller processing method for special width.

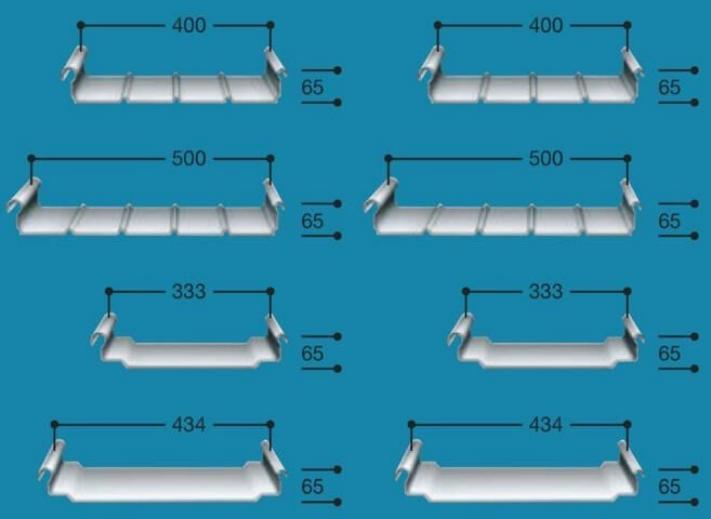

With special shape slitting and cut to length machine.

With special bending and curving machine.

Metal standing seam roof panels machine with slitting and bending machine

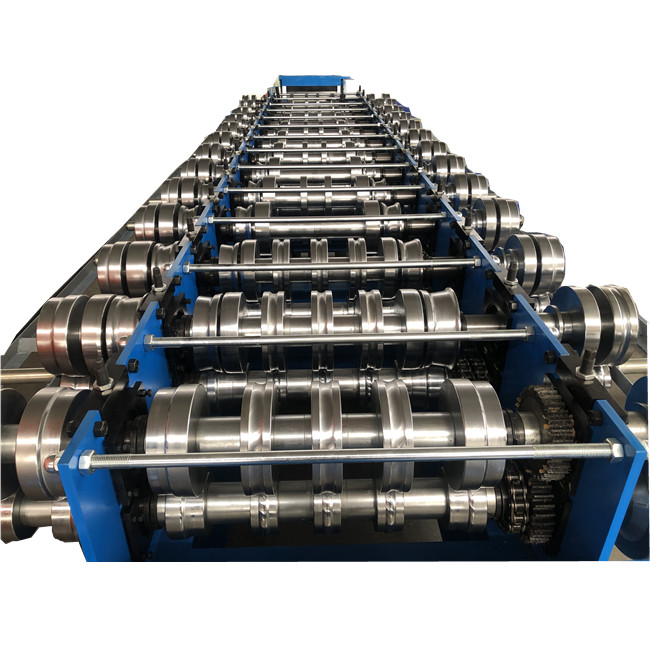

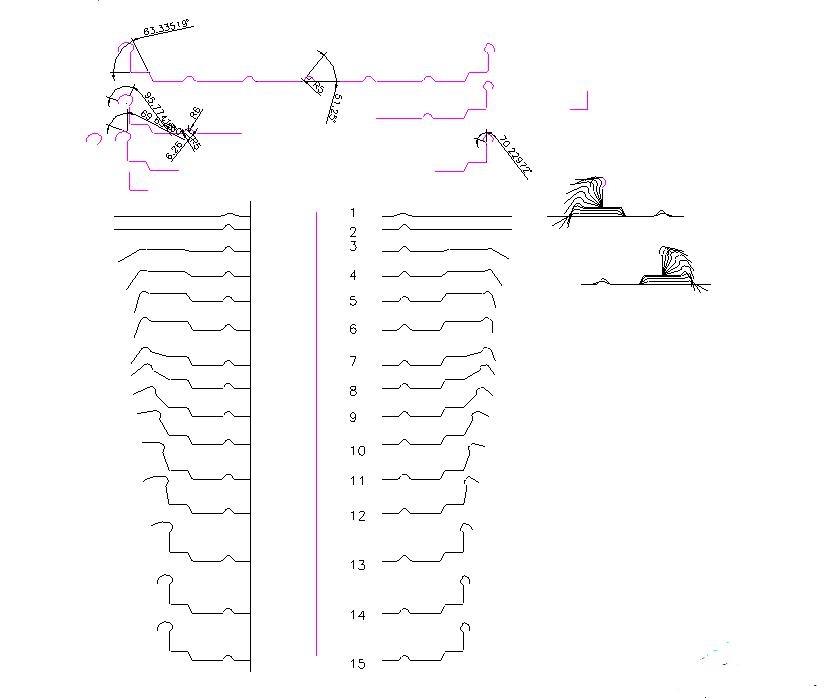

This is the shape changing process;

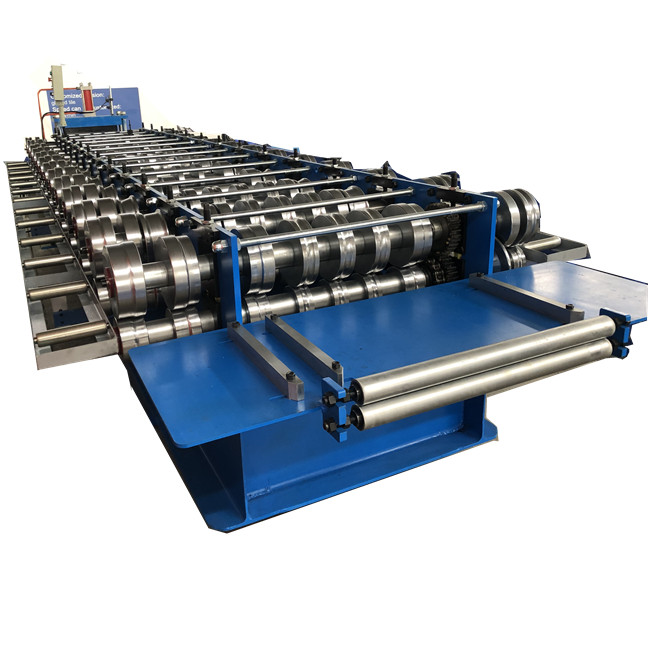

| Technical parameter | |

Length of the main part | 7500 х 1650 х 1450 mm |

Weight of main part | 6 Ton |

Voltage | 380 V/ 50 HZ 3 Phase (as customer’s request) |

Roller fixer | Middle plate welded |

Frame | 350 H steel welded |

Frame thickness | 18 mm thicker to be very strong |

Drive mode | Chain of 1.25mm |

Material of rollers | 45# steel, surface hard chromium plating. |

Material of shafts | 45# steel |

Diameter of shafts | Φ 70 mm |

Number of rollers | 14rollers |

Main power | 5.5kw |

For this standing seam rolling forming machine, it has 3 parts:

1. Standing seam rolling forming machine, which two sides could be used to trimmed the narrow and oblique shape part.

2. It has the slitting and cut to length machine which can help you do the oblique slitting.

3. It has the curving machine, by which you can make various shapes.

About the seam bending rolling forming machine:

1.Equipment size; 1420 in length, 1000 in width, and 1900 in height.

2. Working mode; Three roll feeding, combined with hydraulic and servo motors for molding.

3. Processing scope; Straight board; Fan shaped board (any model within the range of 230-600 can be automatically or manually adjusted).

4. Scope of processing sheet metal; Aluminum magnesium manganese, (0.76-1.2) color plate (0.3-0.7).

5. The working mode is automatic and continuous rolling forming, which can be manually and automatically controlled.

6. Main motor power; 4kw equipped with 5 # reducer (vertical motor).

7. Power of the lifting motor; 0.75KW equipped with RV reducer (horizontal motor).

8. Main engine transmission mode; Gear transmission.

9. Lifting method; The chain is automatically lifted and lowered with the help of a screw.

10. Servo motor power; 2.2KW.

11. Equipment functions; Continuous positive and negative S-bends can be made on the same board.

12. Bending radius; Aluminum magnesium manganese, with a minimum radius of 1 meter for positive bending and 3 meters for negative bending.

13. Roller material; Cr15 quenching and tempering followed by surface plating with hard chromium treatment.

14. Forming speed; 18/min.

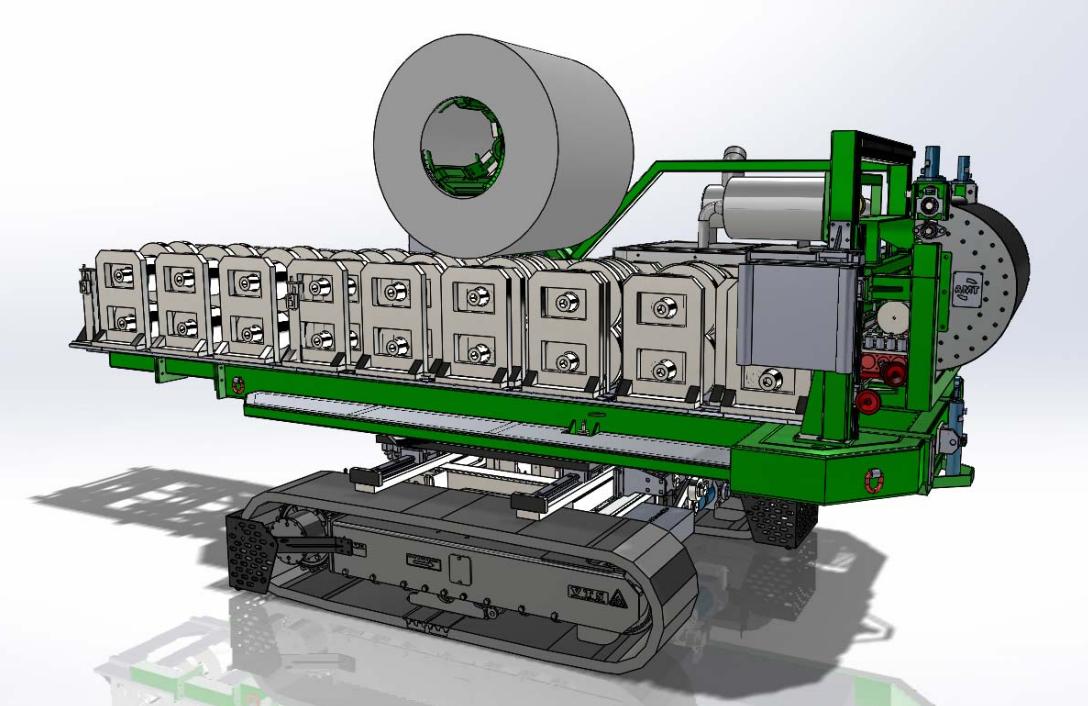

For such standing seam roofing sheet machine we can also design it to the car type for you:

By this type, you can take it to any place, to the work place.

More pictures of the standing seam machine for your reference:

Here is the standing seam machine working videos for your reference: