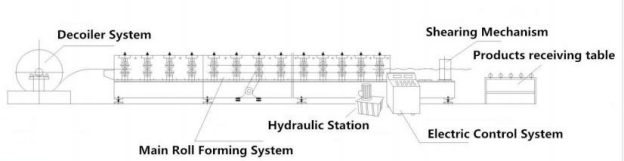

Description:Our roofing sheets machine consists of decoiler, feeding and leveling device, per-shear, roll forming system, hydraulic post cutting, run out table, hydraulic station and PLC(controlling system).Produce standard products with yield strength up to 450Mpa,Long production line, good profile shape on final products; Time saving and labor saving, which is highly improved production efficiency and suitable for current production. This machine is easy to operate and run stable with good precision.

Sheet Corrugated Roll Forming Machine

Small corrugated metal profiles are durable yet weightless.In fact,we are working to profound the best machine to product corrugated or corrugated roof sheet machines.Highly popular for building the roof and side.Corrugated Metal Panels have more recently gained tremendous popularity as modern contemporary roofing and siding.

Our roofing sheets machine consists of decoiler, feeding and leveling device, per-shear, roll forming system, hydraulic post cutting, run out table, hydraulic station and PLC(controlling system).Produce standard products with yield strength up to 450Mpa,Long production line, good profile shape on final products; Time saving and labor saving, which is highly improved production efficiency and suitable for current production. This machine is easy to operate and run stable with good precision.

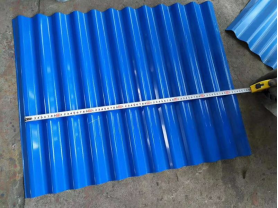

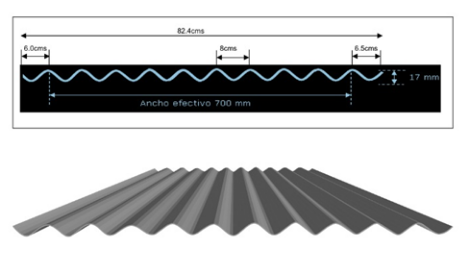

Here is one drawing profile and finished product:

What is a corrugated roofing sheet:

Corrugated metal roofing sheets are commonly used for roofing in a wide range of applications including roofing wall cladding,fences,and screens.

Household constructions such as houses,kiosks,shops,restaurants,etc,...

Industrial workshops such as warehouses,factories,offices,...

Public building such as hospitals,clinics,schools,commissars,departments,theater or amusement parks.

The corrugated metal sheet is designed into rolls,1200mm flat,is put into the corrugated roll forming machine.

Sheet Corrugated Roll Forming Machine

Process flow:

Decoiling→guide&manual pre-cutter→roll forming→cutting→run out table

Technical of the whole line:

5ton manual decoiler | 1.Capacity:5ton 2.Coil diameter:450-550mm adjustable 3.Coil width:Max1350mm 4.Un-powered, manually control steel coil inner bore shrinkage and stop |

Manual pre-cutter | Pre-cutter is suitable for frequent replacement of steel coil equipment,cutting steel coil in advance for easy replacement and reducing the wast of steel coil. |

Main forming machine | 1.Main frame:400mm H beam structure, with 20mm thickness welded steel middle support plate. 2.Forming station:24 stations 3.Roller material:High grade 45# steel,chromed treatment,which makes the rollers surface more smoothly, improve the hardness and prevent abrasion, anti corrosion increase of service life 4.Shaft material:High grade 45#,Tempering treatment, prevent deformed and improve the hardness 5.Shaft diameter:80mm,solid 6.Motor power:7.5kw 7.Speed:0-20m/min 8.Voltage:380V,50HZ,3P(Or as request) 9.Transmission:By 1inch double chain,Chinese famous brand HRB |

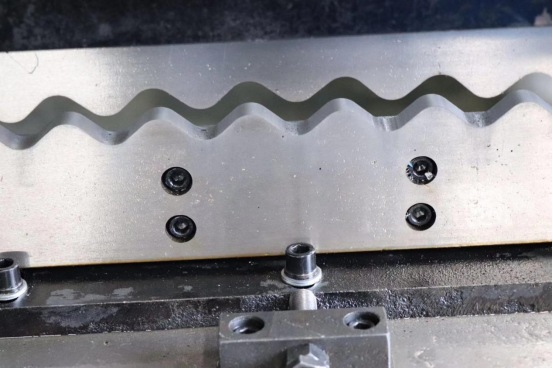

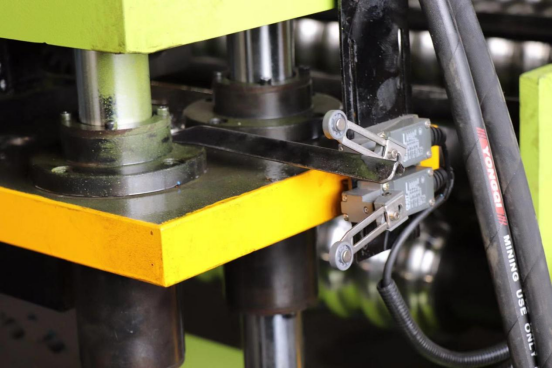

Hydraulic cutting deivce | 1.Blade material:Gcr12 quenched treatment 2.Length tolerance:±1mm 3.Hydraulic power:5.5kw 4.With air cooling system in the hydraulic station 5.Cutting feature:Steady and safe working condition and low sounds. 6.Oil tube and wires connection:All the tubes and wires will be marked by the numbers or letters,so that it will be easy to connect for the new. |

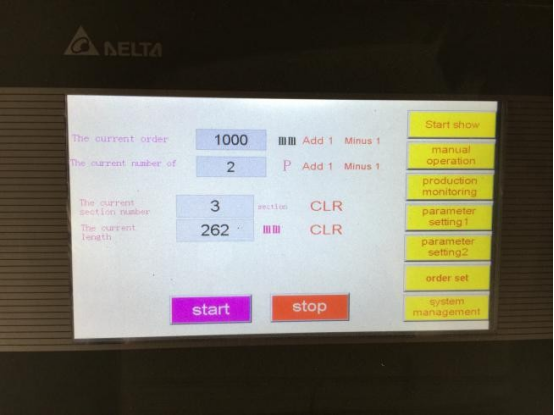

Control system | 1.Frequency converter:Delta 2.Screen:touch screen 3.PLC brand:Delta 4.Language:Chinese and English(Or as customers’ request) 5.Encoder:Omron 6.Feature:The control system support multi orders input,it can match different production needs 7.Functions:Cutting length control,cutting quantity control,and speed control |

Run out table | 1.Length:3m 2.Quantity:2sets |

Spare parts | 1. Tool box:1 set 2. 4pcs fuse, 2pcs travel switch,Chains 2pcs |

Images: