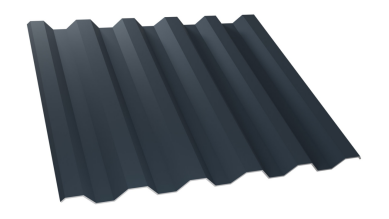

Description:We are engaged in the manufacturing, supplying, and exporting of High quality (7.2 Panel) Metal Roofing Panel Machine. Our offered range of machines are highly appreciated by the clients all around the world for its unique property like smooth and flexible performance and robust construction. Further, this High quality (7.2 Panel) Metal Roofing Panel Machine is widely used for manufacturing steel sheets that are used for the roofs of fabricated buildings.

High quality (7.2 Panel) Metal Roofing Panel Machine

We are highly renowned manufacturer, exporter and supplier of a wide range of High quality (7.2 Panel) Metal Roofing Panel Machine. It is manufactured by our professionals using quality approved components that is procured from the reliable vendor of the market, in compliance with international quality standards to ensure flawlessness at users’ end. This machine is quality tested and is offered in various technical specifications and can be availed in bulk quantities. Clients can avail offered machine from us at most economical price.

We are engaged in the manufacturing, supplying, and exporting of High quality (7.2 Panel) Metal Roofing Panel Machine. Our offered range of machines are highly appreciated by the clients all around the world for its unique property like smooth and flexible performance and robust construction. Further, this High quality (7.2 Panel) Metal Roofing Panel Machine is widely used for manufacturing steel sheets that are used for the roofs of fabricated buildings.

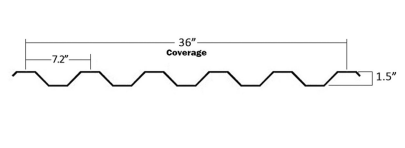

Here is one drawing profile and finished product:

High quality (7.2 Panel) Metal Roofing Panel Machine

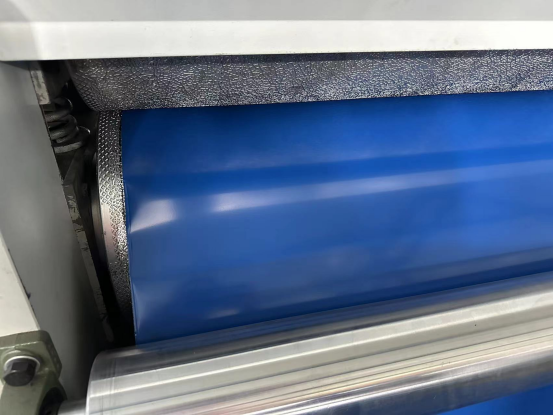

Salient features of High quality (7.2 Panel) Metal Roofing Panel Machine:

• With PLC touch screen control for accurate tuning of machine operations

• Equipped with hydraulic Decoiler for easy loading & unloading of coil

• MS forged, grinded & hard chromed rollers ensure precise formation of products without leaving any marks

• Uniform distribution of material around its axle provides longer life to structures long life

• Works on printed or galvanized materials, which reduce cost & saves time

• Can perform multiple operations online like punching, embossing, forming, cutting which increases productivity

• Cold roll forming provides cut to length sizes to avoid any wastage of material

• Gives the engineers & planner enough flexibility to create unique structures

• Efficient control panel to set important operative parameters easily

• Aesthetically and ergonomically build machine for best performance

• Produced in an advanced state of the art manufacturing facility

• World class bought out items for optimum operations

• Designed to work 24 hours, round the clock

• Operator friendly machine, hence easy to operate and maintain

• Low maintenance and operating cost

• Sturdy design to ensure long life and trouble-free operation