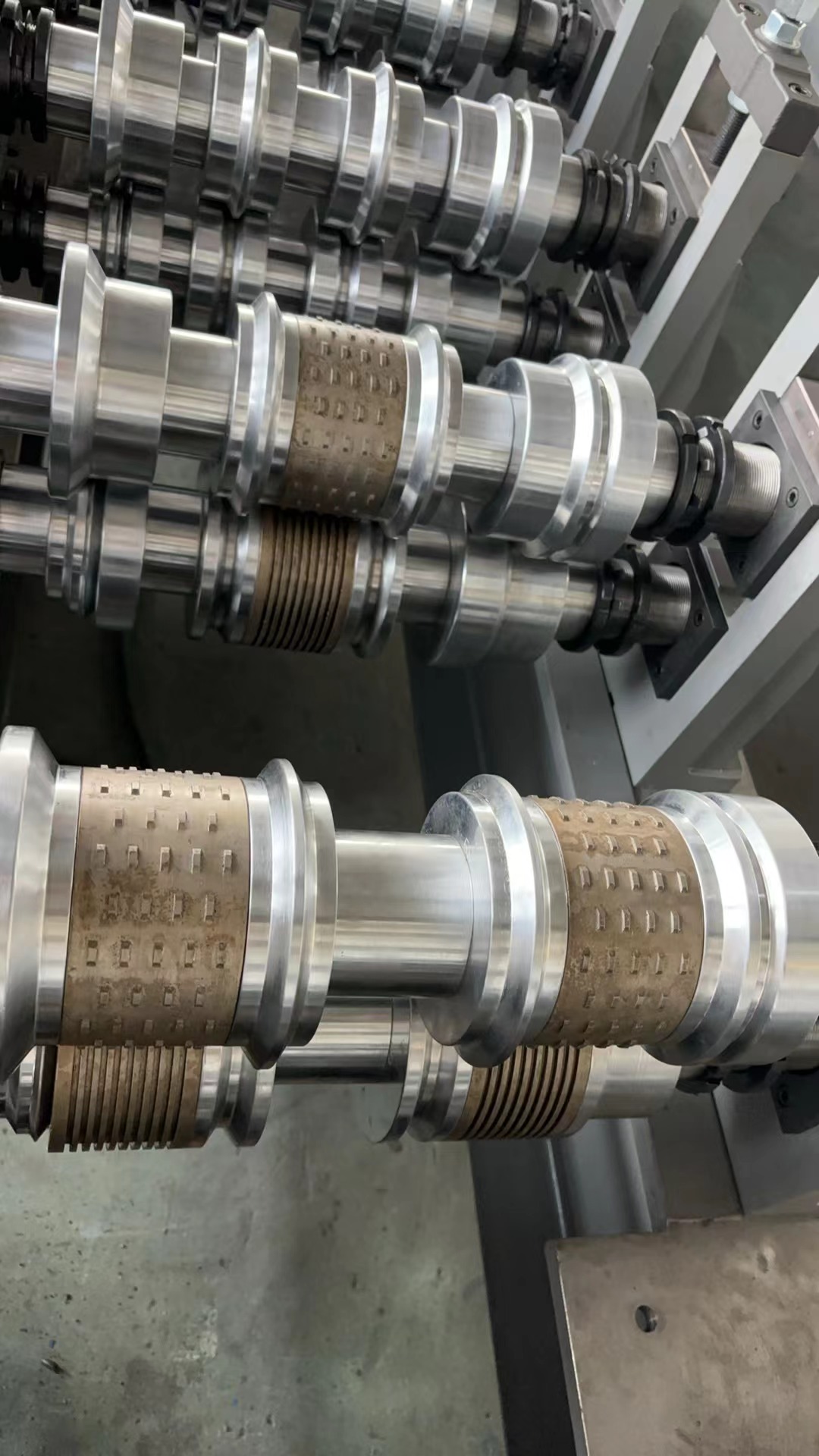

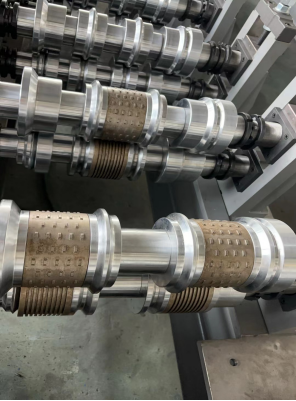

Description:Petersen Flush Panels are formed on precision roll-forming equipment that includes in-line corrective levelers. Corrective leveling works to remove typical metal conditions including coil set, crowning and edge wave. In-line leveling capabilities allow us to work with source material that is “still-water” flat. The result is a panel that exhibits superior flatness.

Metal Soffit and Wall Panels Machine

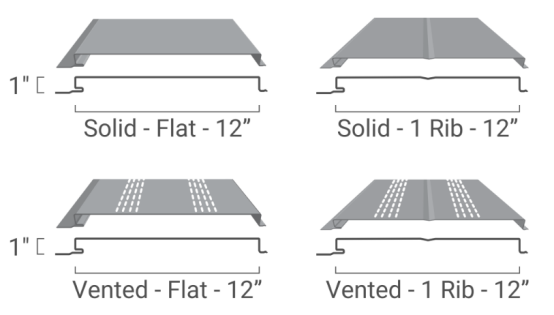

ZTRFM Flush Panels are designed for wall, fascia and soffit applications where a flush or flat appearance is desired. A rounded interlock leg and concealed fastening system improves the flush appearance while providing additional strength. Panels are factory-formed to length to minimize field cutting. ZTRFM Flush Panels are intended for use in vertical wall, fascia and soffit applications.

Petersen Flush Panels are formed on precision roll-forming equipment that includes in-line corrective levelers. Corrective leveling works to remove typical metal conditions including coil set, crowning and edge wave. In-line leveling capabilities allow us to work with source material that is “still-water” flat. The result is a panel that exhibits superior flatness.

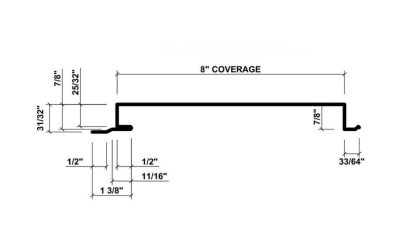

Here is one drawing profile and finished product:

Profile drawing for reference:

Metal Soffit and Wall Panels Machine

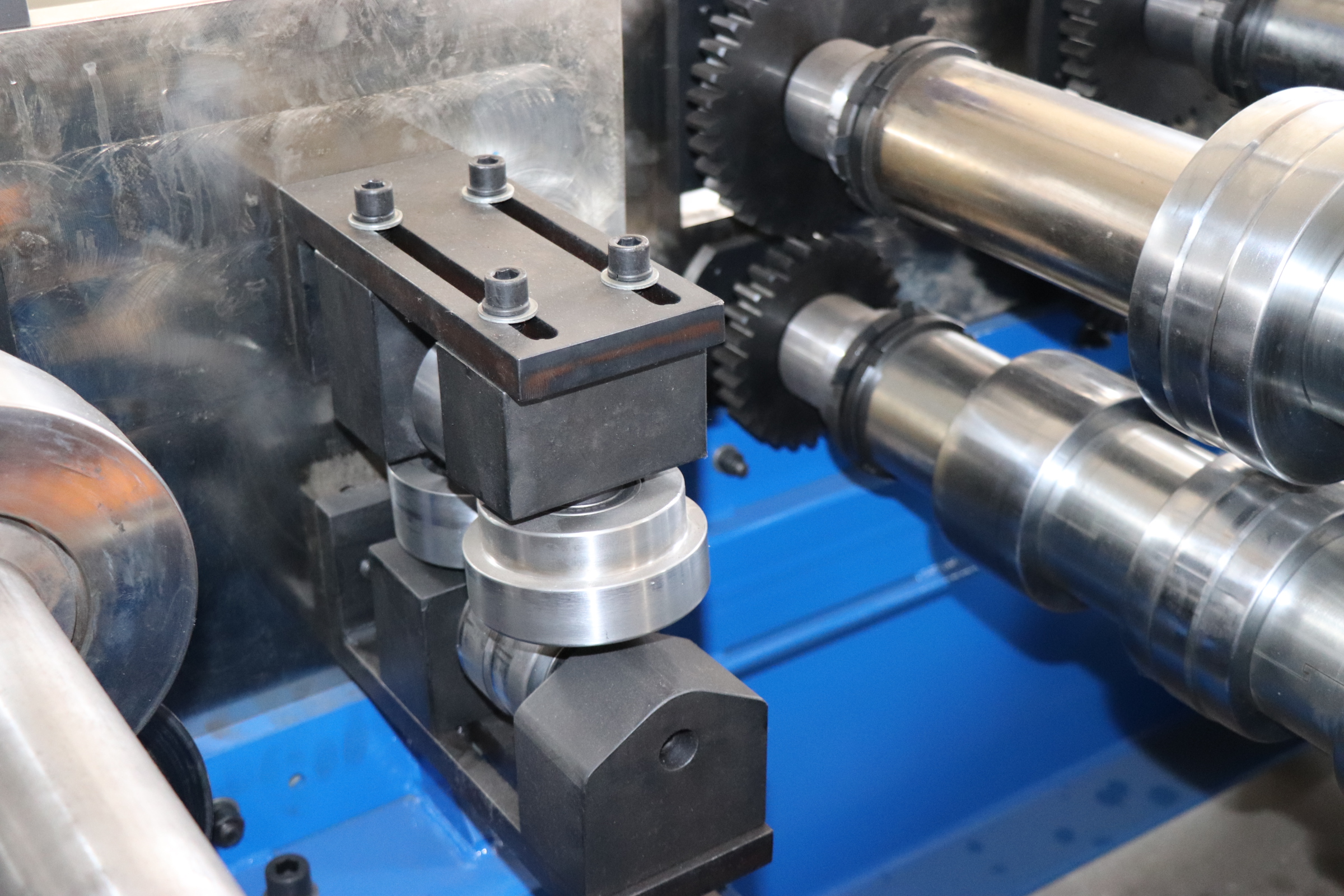

The Metal Soffit and Wall Panels Machine process :

Options & Accessories:

Digital Controller for fully automatic operation

“Quick Release” Seam Style Ribs

Perforation Die Attachment for Soffit venting

Power Upgrade to perforate and roll form 24 – 22 ga Steel – Required

3,000 and 5,000 Lbs. capacity Decoilers

Machine Stand with Leveler Pads