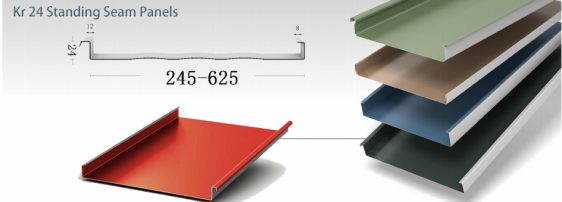

Standing seam roll forming machine

Standing seam roof panel forming machine is a kind of machine specially used for the production of roof panels,which can process metal materials,such as steel plate,aluminum plate,color steel plate,etc.,so that it forms a roof panel with a specific shape and size,which is widely used in the construction industry,especially in the roofing system of steel structure buildings.Provide high quality roofing panels for large buildings such as factories,warehouses,gymnasiums and exhibition halls.

Some profile pictures:

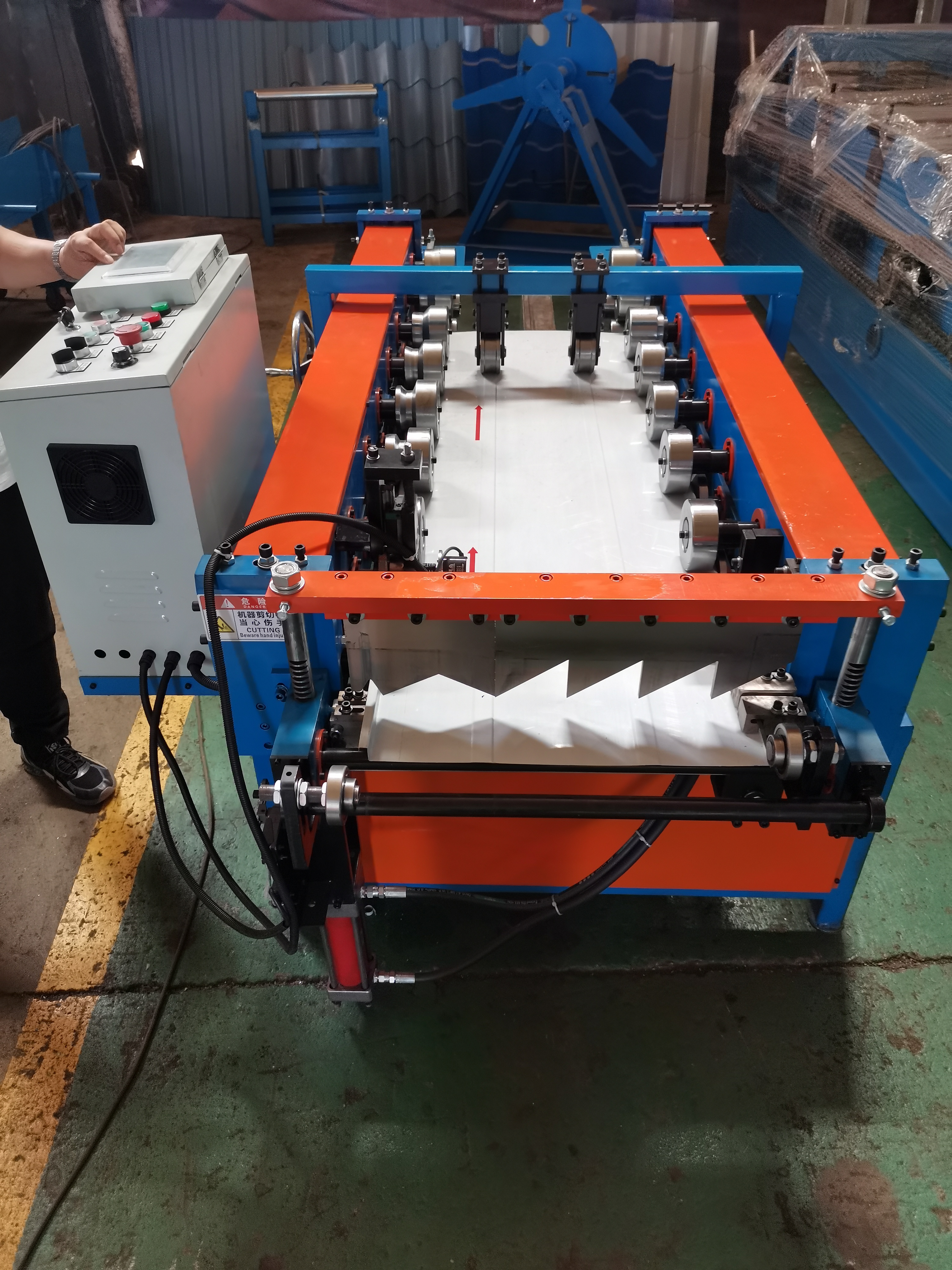

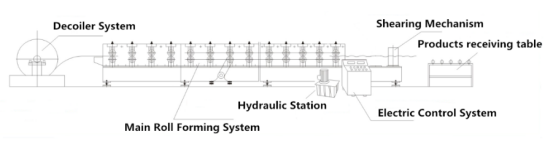

Work flow of standing seam forming machine:

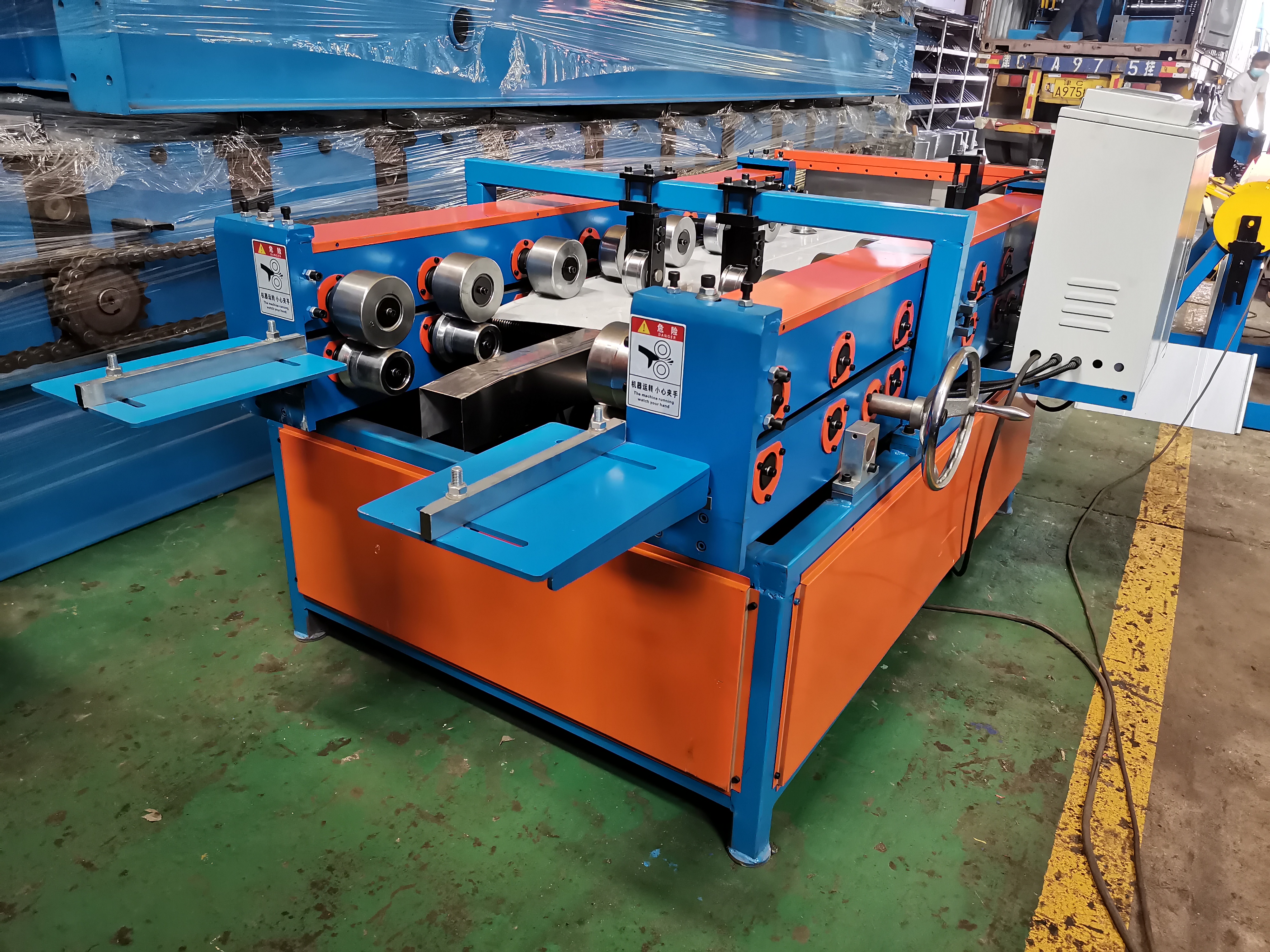

Standing seam roll forming machine

Manual decoiler

Regular and passive type. simple in structure and low in cost.Equipped with manual wheel and brake.Not appear the deposition of material.

Hydraulic Shearing

The blade material is Cr12.Two lines of bolts and nuts to fix each blade, which has high stability.

Hydraulic Station

The oil of 46# and large valve with high cost which is not easy to block.

The power is 4kw.The capacity of the fuel tank is 80 liters.

Equipped with air cooling devices to prevent the hydraulic oil from overheating and affecting the operation of the machine.

The motor of hydraulic station is a Chinese standard brand with good quality.

Hanging PLC control system

The regular language of the panel is Chinese or English.It can be customized according to your needs.

We adopt well-known brands such as Delta, Schneider,Siemens.PLC brand is Delta and counter is Omron.

You can choose to install remote operating system of PLC. So that our engineers will debug it for you remotely when there is a problem with the machine.

Product features:

Raw material :PPGI,PPGL, GI,GL

Forming speed:20m/min(customized)

Decoiler: Manual decoiler

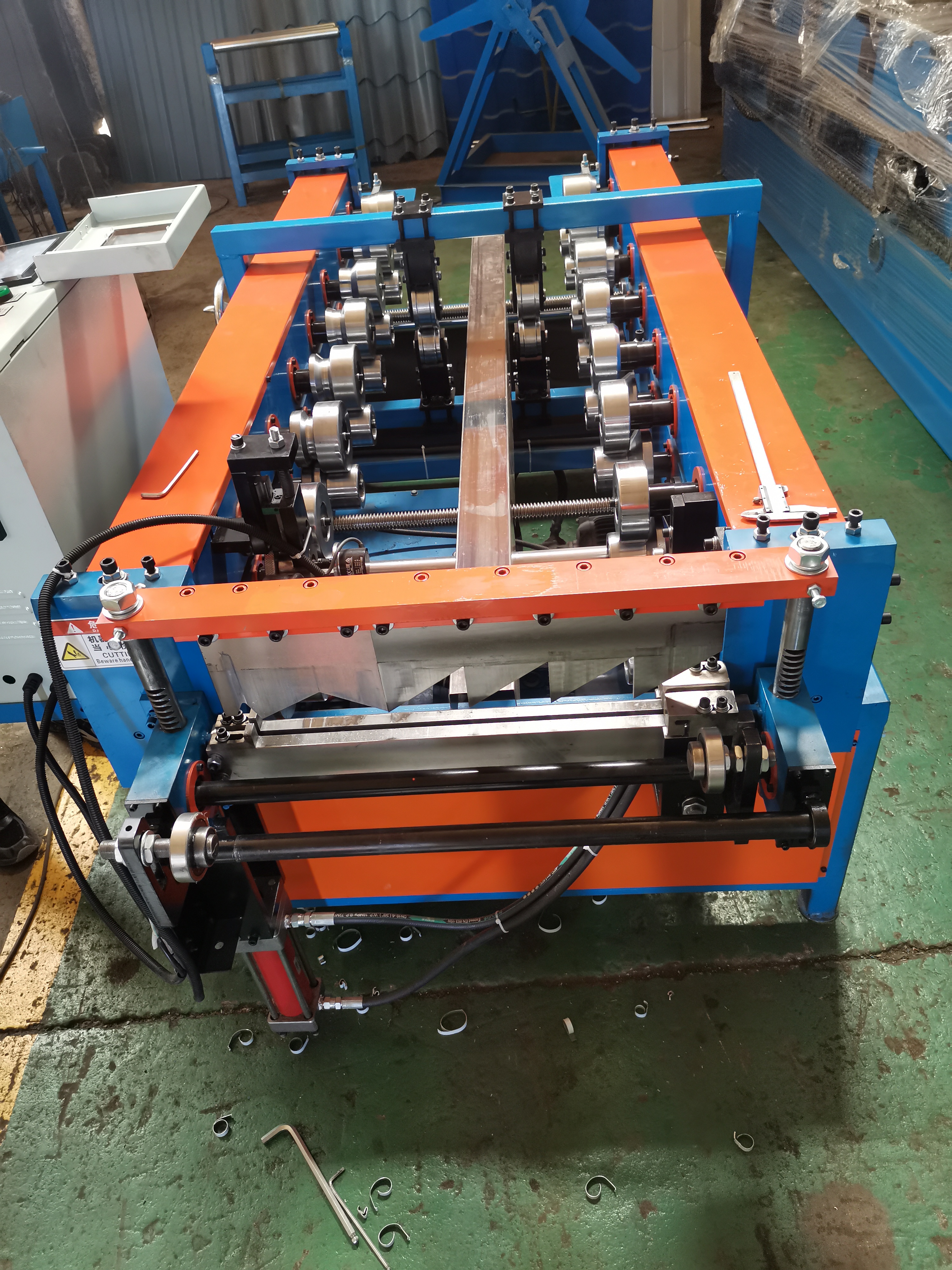

Roller station:18 rows ( As technical requirements )

Diameter of shaft:80mm solid shaft

Material of rollers:45# steel, hard chrome plated on the surface

Frame:350H beam welded

Drive:Chain transmission

Cutter:Cr12 material

Motor power:5.5kW

Hydraulic station power:4kW

PLC:Delta