Description:Snap lock standing seam rolling machine produces roof panels with single snap lock seam for quick installation without special roofing tools of straight and trapezoidal form.Snap lock standing seam rolling machine operates with all roofing metal types (coiled and sheet steel, including that with polymer coating, copper, including patinated one, aluminium, and zinc titanium). The roofing panel width is adjusted stepwise.

The snap lock seam panels are indispensable for use on simple double-pitch roofs with pitch angle at least 15°. The machine allows producing roof panels of any length on a construction site as well as at a manufacturing facility.

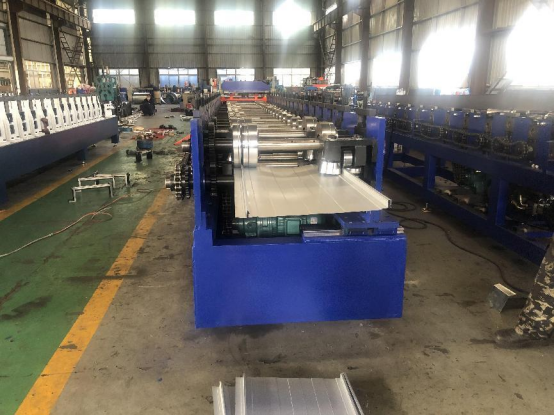

Snap lock standing seam rolling machine

As a roof specialist you might want to look for something to facilitate the installation of snap lock panels for pitch roofs with minimum angle of 15°. The roofing roll forming machine does exactly this job. The equipment is meant for easy manufacture of snap lock standing seam panel. The machine works with any kind of metal. You can adjust length and width manually.

As well as that you can regulate the form of the end product: whether it be straight or trapezoidal. You can also change the pressure force of vertical rollers which will effect the stiffness and thickness of the metal panel. There is also an option to mount extra rollers for half round and trapezoidal ribs. The machine also drills holes for concealed fastening of the panels.

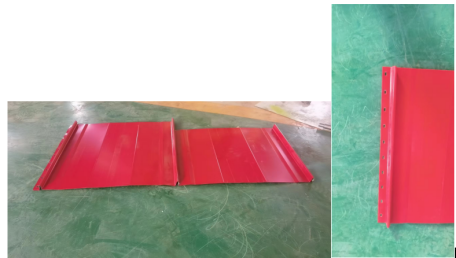

What is the Snap lock?

Button installation.It can be installed without using a machine. When the installation only need to press, when heard a click on the installed. Installation is easy and quick, and it also saves costs.

Here is one drawing profile and finished product:

Snap lock standing seam rolling machine

Our machines can create customized panels. The machine may be configured to generate panels in a variety of colors, coatings, and profiles based on the customer’s needs. Our machines are appropriate for both commercial and household use. Because of the requirement for roll-formed panels with few or no field seams. Furthermore, our machine-made panels are simple to install and include snap-lock technology, which eliminates the need for additional tools and fasteners. This snap-on design expedites installation, saving installers and clients both time and money. This machine also produces heat-resistant, long-lasting panels that require no maintenance.

Snap lock standing seam rolling machine is one-of-a-kind in that it can create panels up to 24 gauge. It employs a multi-stage forming process to assure constant panel quality, fast production, and little waste. The machine is simple to use and can be configured to generate plates of various lengths and widths. The machine also has safety measures to safeguard the operator’s safety while operating it.

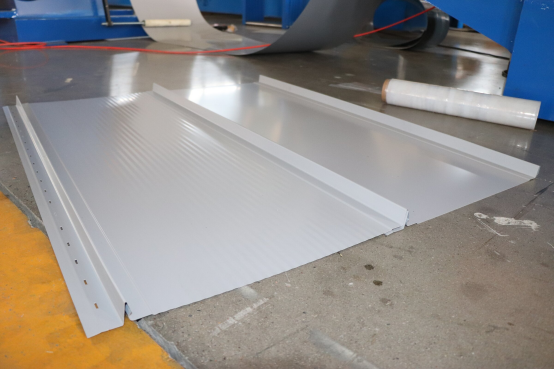

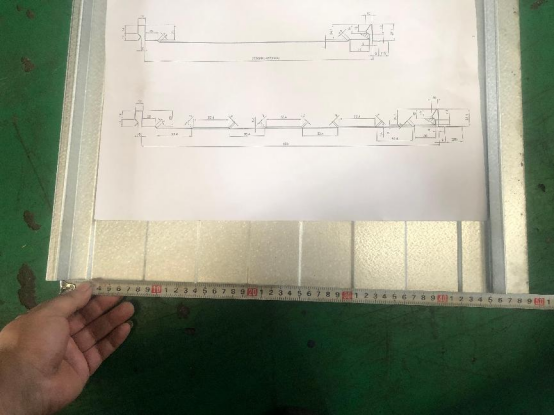

The above introduction is a fixed version of the vertical Snap lock standing seam rolling machine . Here is an adjustable Snap lock standing seam rolling machine . This is an adjustable width Snap lock standing seam rolling machine and you can customize any width you want. This kind of machine is more diverse and flexible, and can meet more needs.

Give an example:

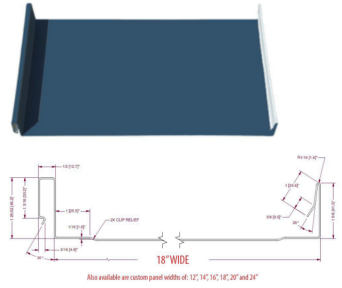

SPECIFICATIONS:

Rib Height: 1.75”

Overall Width Standard: 18”

Custom Widths Available: 12”-20”

Coil Feed: 24”

Warranty: 30 year limited*

Coverage AreaRoof: 18”(Standard), 16”, 14”, 12” alternate widths available

Available Gauges: 24, 22

Substrate: AZ 50 Minimum

Finish: Cool 500 – PVDF

Fasteners: Concealed

Panel Length: 1’ to 52’

Recommended Minimum Roof Slope: 3/12**

Installation: Installation over a solid substrate with or a an underlayment between the panel andthe substrate.

Here is one drawing profile and finished product:

Advantages of the Snap lock standing seam rolling machine System:

1.The waterproof and drainage function of the overall structure, no matter what the shape of the building is, the joints can be fully articulated. There are no nail holes in the entire roof, which allows the roof to expand and contract freely when the temperature changes, avoiding temperature stress, and eliminating the potential risk of water leakage caused by the screw fixing method of the system.

2.No need for chemical sealants, eliminating pollution and aging problems.

3.Mature design of integrated roof opening and lightning protection system.

4.Good air permeability, keep the overall structure dry naturally for a long time, prolong the service life of the building.

5.The shape of three-dimensional curved arc is unique and easy to process.

6.The structure is simple, light and safe, and can withstand high negative wind pressure, especially in typhoon and heavy rain areas.

7.It is also suitable for old roof renovation and old roof plus new one.

8.The construction is safe, convenient, fast, accurate and economical.