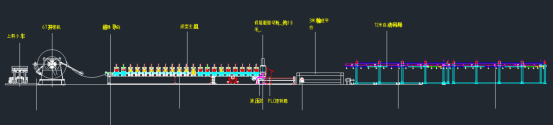

Description:Our roofing sheets machine consists of decoiler, feeding and leveling device, per-shear, roll forming system, hydraulic post cutting, run out table, hydraulic station and PLC(controlling system).Produce standard products with yield strength up to 450Mpa,Long production line, good profile shape on final products; Time saving and labor saving, which is highly improved production efficiency and suitable for current production. This machine is easy to operate and run stable with good precision.

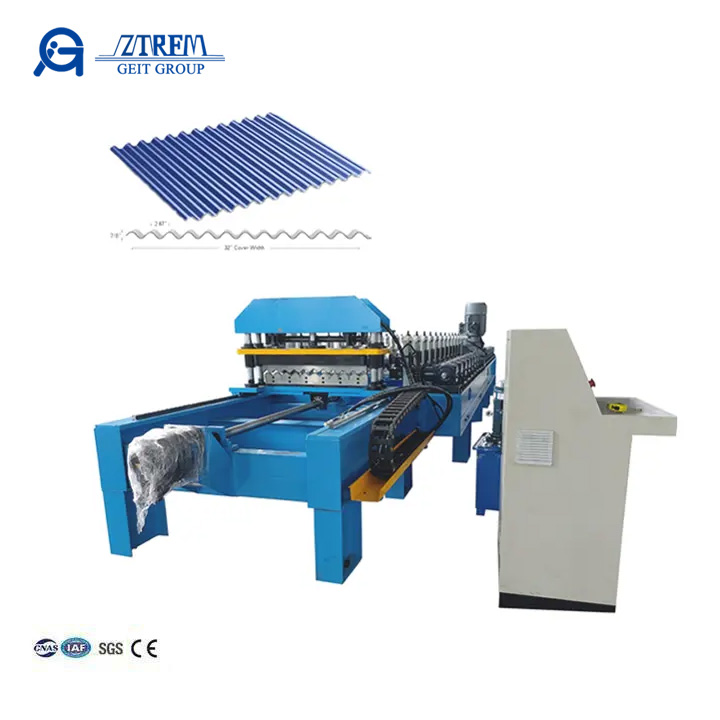

Metal PBC Panels Roofing Sheet Machine

Small corrugated metal profiles are durable yet weightless.In fact,we are working to profound the best machine to product corrugated or corrugated roof sheet machines.Highly popular for building the roof and side.Corrugated Metal Panels have more recently gained tremendous popularity as modern contemporary roofing and siding.

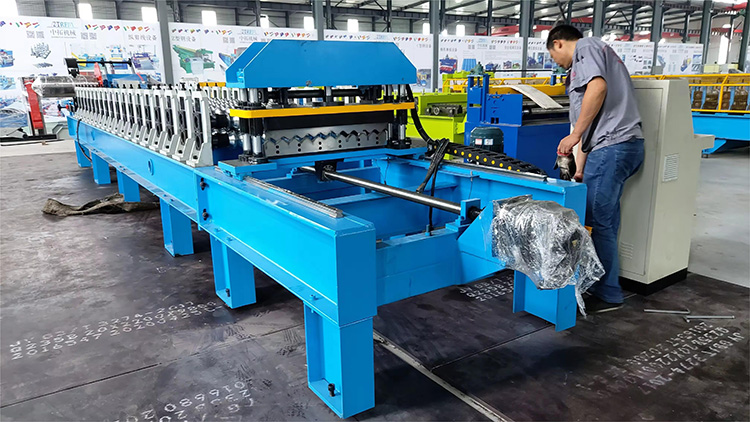

Our roofing sheets machine consists of decoiler, feeding and leveling device, per-shear, roll forming system, hydraulic post cutting, run out table, hydraulic station and PLC(controlling system).Produce standard products with yield strength up to 450Mpa,Long production line, good profile shape on final products; Time saving and labor saving, which is highly improved production efficiency and suitable for current production. This machine is easy to operate and run stable with good precision.

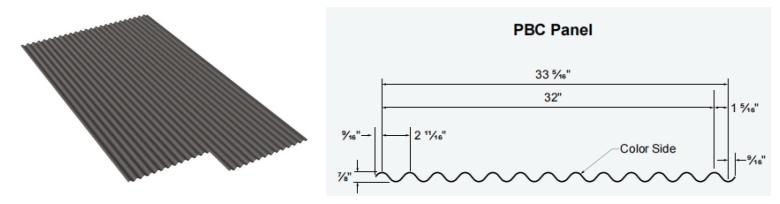

Here is one drawing profile and finished product:

What is a PBC Panels Roofing Sheet:

The PBC panels can be used for both roof and wall applications. PBC panels are attached to a building structure with exposed fasteners and are often used in horizontal wall applications.

Metal PBC Panels Roofing Sheet Machine

Processing Flow:

Decoiler→feeding material→roll forming→cutting→receiving the product

Feeding Device

The metal coil is fed into the machine through a set of rollers and guides to ensure a smooth and continuous process.

1. Utilizes rubber rollers to safeguard the surface of raw materials.

2. Easy adjustment for varying thicknesses of raw materials using handwheels.

3. The platform width is conveniently adjustable via handwheel, featuring built-in bearings to safeguard the steel sheet’s edges.

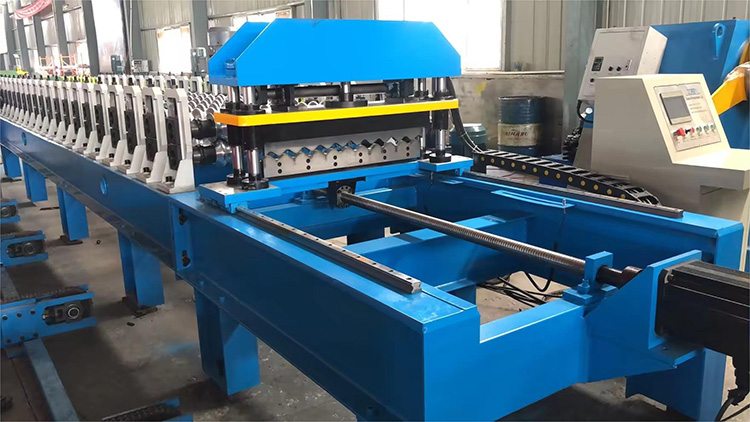

Roll Forming Device

This is the heart of the machine, where the metal sheet is formed into the corrugated profile. A series of specially designed rollers and dies shape the metal as it passes through this section.

1.45# Steel,Chromed Treatment (Cr Thickness:0.05 Mm), Anti-Corrosion,Increase Hardness, thick chromed good hardness for long service time.

2. Each roller has number and with keynotes, it can fix on the shaft stablely

Transmission device

Gearbox transmission,stable and no loose.

Hydraulic Cutting Device

After the metal sheet has been corrugated, a cutting mechanism is employed to cut the sheet to the desired length. This can be achieved through various methods, such as shearing or rotary cutting.

1.Work type:hydraulic servo track cutting servo motor 5.5KW

2.Driving method:By pillar type Cylinder

3.Hydraulic motor power:4 kw

4.Cutter material :GB-Cr12 with heat treatment

5.Cutting length tolerance ±10m/2mm

PLC control system

Modern machines are equipped with a control system that allows operators to set parameters, monitor the production process, and make adjustments as needed. This may include features like touchscreen interfaces and programmable logic controllers (PLCs).

Brand

PLC brand : Delta

Inverter brand: Delta Low electric part: Schneider

Encoder: Omron

Function:

1.Adopted aviation plugs,easy installation.

2.Full automatic easy operation.

3.Operation language:English(provide customized)

4.National coinsurance,spar parts Brand Siemens and Schneider

Hydraulic station

7.5kw motor with cooling system for long time using.

Automatic Stacker

3m Conveyor

Automatic Stacker

6m Automatic Stacker