Description:Metal (including steel and aluminum) usage in construction is increasing more than any other building product out there. Steel roofing and steel walls are all manufactured on roll formers.Rollforming is a process by which a flat coil of steel is fed through rolls and formed to make a finished product.

Roof and Wall PBU Panel Rolling Forming Machine

We are one of the leading suppliers and manufacturer in china and have been supplying and making roll forming equipment for the metal building construction industry for a long time.

We are Specialists in roll forming machines for the manufacture the production of building construction, such as for the metal roofing and wall, various trapezoidal profiles can be custom manufactured. We build complete roll forming lines for roofing & cladding lines.

Our roof panel roll forming machines are special for manufacturing high quality steel roof & wall cladding panels, aluminum Lock Roofs. With our engineer’s many times improvements, the Ribbed Roof Panels machine design is perfect. The Ribbed Roof profile surface is smooth and power fee is lower, driven by chain.

It is specially designed forming roofing corrugated sheet, wall panel,floor deck, under mass-production. The highest speed of the line can reach to 30 M/min working with fully automaticlly stacking system.

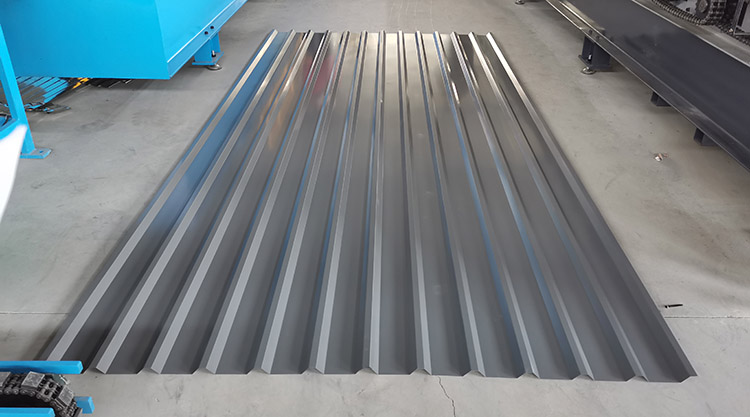

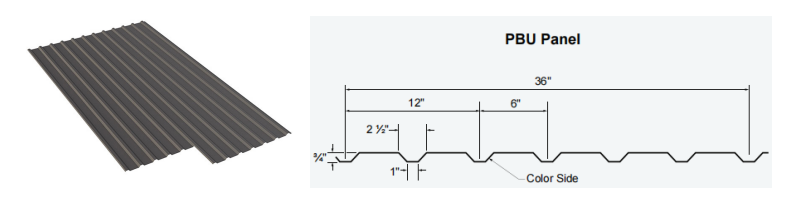

Here is one drawing profile and finished product:

What is a PBU Panel:

The PBU panel is an exposed fastener system that can be used for both roof and wall applications and can be installed directly over purlins or joists.

Roof and Wall PBU Panel Rolling Forming Machine

High Speed Trapezoidal Roofing Machine technical parameters:

Formed Material: PPGI,GI,AI

Thickness: 0.3-1.0mm

Width: 1000mm/1250mm(customized)

Roller station: 26 rows(As your requirement)

Diameter of shaft: 80mm solid shaft

Material of rollers: 45# steel, hard chrome plated on the surface

Machine body frame: 350 H steel

Motor Power: 5.5KW

Voltage: 380V 50Hz 3Phase(As your requirement)

Control system: PLC

Forming Speed: 0 – 60m/min

Cutting type: Hydraulic cutting

Hydraulic power: 7.5kw

Cutting blade material: cr12mov material, no scratches, no deformation

Cutting tolerance: +/-1mm

The advantage of High Speed Trapezoidal roll forming machine:

We have the capability to manufacture different types of roof sheet machines based on client specifications. This particular machine excels in high-speed operation, offers enhanced stability due to gearbox transmission, and boasts a robust cast iron structure.

Product display:

1.Hydraulic decoiler

Empowered with automated functionality, enabling autonomous operation.

Automatically adapts the decoiler to accommodate coils based on their diameter.

Equipped with a pneumatic braking system for enhanced control and safety.

Includes a press arm mechanism to secure coils and prevent loosening.

2.Roll forming device

Roller station: 26 rows(As your requirement)

Diameter of shaft: 80mm solid shaft

Material of rollers: 45# steel, hard chrome plated on the surface

Machine body frame: 400H steel

Drive chain: 1.2inch(As your requirement)

3.Hydraulic cutting device

We utilize a pillar cutting system structure, ensuring stable cutting operations. The hydraulic oil pump station supplies power to the cutting system, facilitating efficient and reliable cutting processes.

4.PLC control System

PLC brand: Delta(Taiwan)

Frequency converter brand: Delta(Taiwan)

Encoder: Omron

Function: Automatic control the length,quantity and batch