Description:A standing seam roofing panel roll former is a specialized machine used in the construction industry to produce standing seam roofing panels. These panels are widely used in commercial and residential buildings due to their durability, weather resistance, and aesthetic appeal.

Standing Seam Metal Roofing Snap Lock Panel Machine

Standing Seam Metal Roofing Snap Lock Panel Machine is designed and manufactured by our company as one of the flagman equipment for metal roofing panels production. Following machine makes standing seam roofing panels with self-closing lock on sides (snap lock).

The main advantage of such lock system is the easy way of installation: to connect two panels with each other you just need to cover bottom part with top part and press it with some force, you will hear specific click noise at this very moment. That is why name of system is self-closing lock one. Comparing to standard standing seam roofing panels with mechanical lock which you need to close with special tools or equipment, snap lock panels are much easier to install and don’t require additional expensive devices for work.

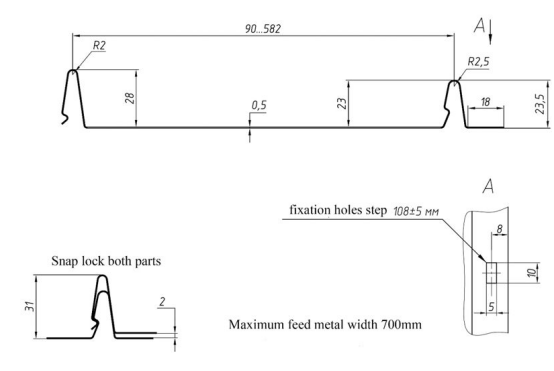

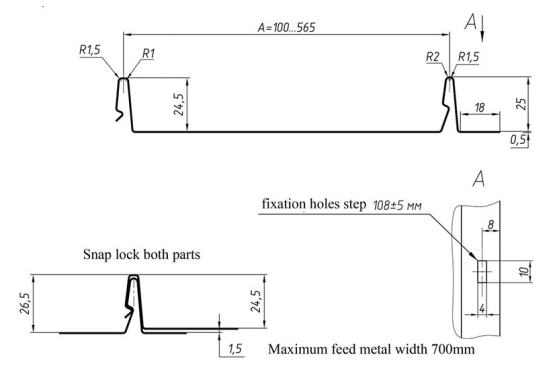

To fix panels at the roof frame you can use standard self-tapping screws, to make it possible, while rolling machine makes special fixation holes on one side of roofing panels. Such simple product design also helps to save costs and make installation process easier, not spending money on clips purchasing, comparing to the standard standing seam metal roofing with mechanical lock installation. So standing seam roofing with snap lock is easier to install, does not require high skilled employees and cut expenses for additional machines purchases.

Total high of panels - 31mm

According to customer preferences machine can be produced to make 26mm roofing lock high

Standing Seam Metal Roofing Snap Lock Panel Machine

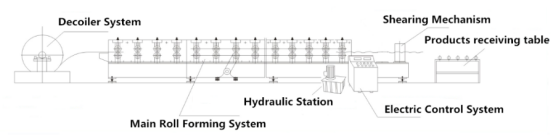

Work flow of standing seam forming machine:

Machine has 10 pairs of forming rolls.

One of the rolls has special punching parts so can cut fixation holes at roofing panel for further installation operations. Cutting tools are made from tools steel with heating and polishing, so have longtime working period.

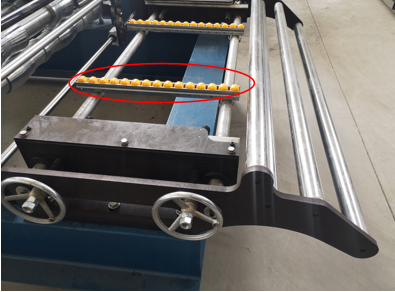

Maximum metal width can be 700mm, minimum 250mm. Standing Seam Metal Roofing Snap Lock Panel Machine is width easy adjustable one, so to adjust machine from one panel width to another you just need to rotate special handle.

Rolling length – unlimited

Rolling speed (m/min.): about 10

Standing Seam Metal Roofing Snap Lock Panel Machine includes safety covers to protect working parts of machine from foreign objects.

Snap lock machine can work with various types of metal: galvanized steel, copper, aluminum, color coated metal, etc.

Uncoiler

It is used to support the steel coil and uncoil it in a turnable way. The steel coil is uncoiled by automatic.

Entry Beach

Put the raw material(steel plate) through the beach to manufacture and process, it can guarantee that the products are neat, parallel and everything is uniformity. Please refer to the equipment regulation to know the function of locate angle iron.

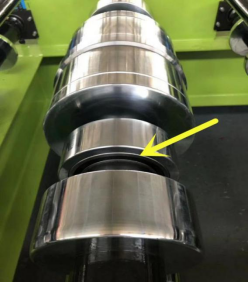

Rollers

In order to get high quality product, our machine adopts welded steel frame structure, AC frequency conversion motor reducer drive, chain transmission, roller surfaces polishing, hard plating, heat treatment and chrome coating.

Computer Control Cabinet

It adopts PLC to control. The target piece`s length is adjustable and digit of it can be adjusted. Computed mode has two modes:automatic and manual one. The system is easy to operate and use.

Hydraulic Station

It is derived by a Gear Pump. After filling the hydraulic oil into the hydraulic oil tank, the pump could drive the hydraulic cylinder to realize the cutting function.The system includes a set of hydraulic tank, a set of a Gear Pump, two hydraulic pipes .and two sets of Solenoid Valves.

Shearing Mechanism

It adopts the hydraulic drive and automatic location to decide the dimension and cut the target products. Material of blades: Cr12 Components:It contains one set of cutting tools, one hydraulic tank and one cutter machine.