Description:Box profile roofing sheets are currently our most popular product as they offer a modern alternative to the older corrugated style at a very competitive price. In the market, each box profile roofing sheets price around 6.5USD/ meter.

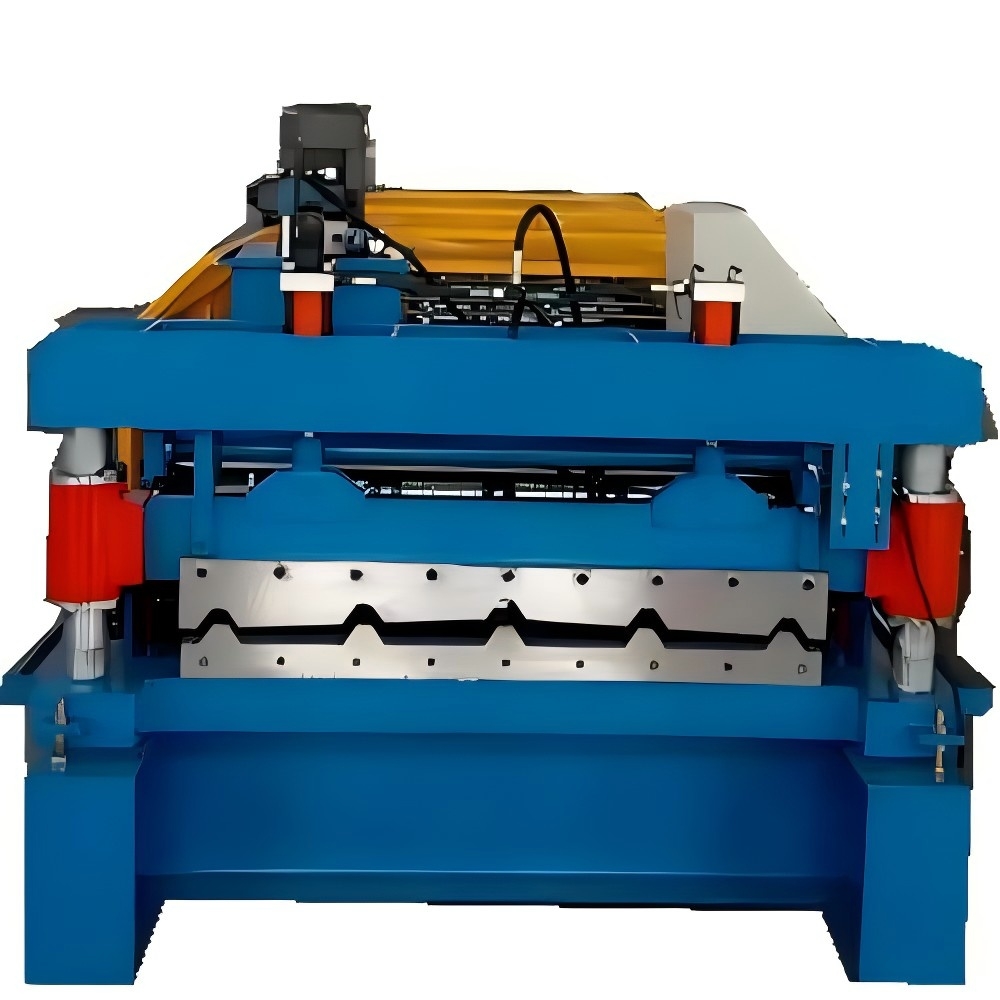

Metal Box Profile Roofing Sheet Rolling Machine

Box profile roofing sheets are currently our most popular product as they offer a modern alternative to the older corrugated style at a very competitive price. In the market, each box profile roofing sheets price around 6.5USD/ meter.

What Box Profile Roofing Sheets?

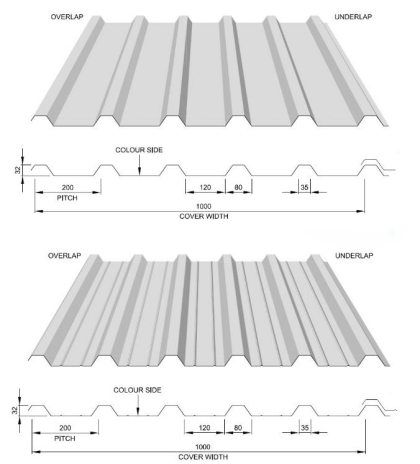

Box Profile Roofing Sheets consist of six profiles and five valleys where the water runs. The profiles are 32mm deep and at 200mm centres. For extra support and stability, two extra ribs can be roll formed into every valley of the sheet.

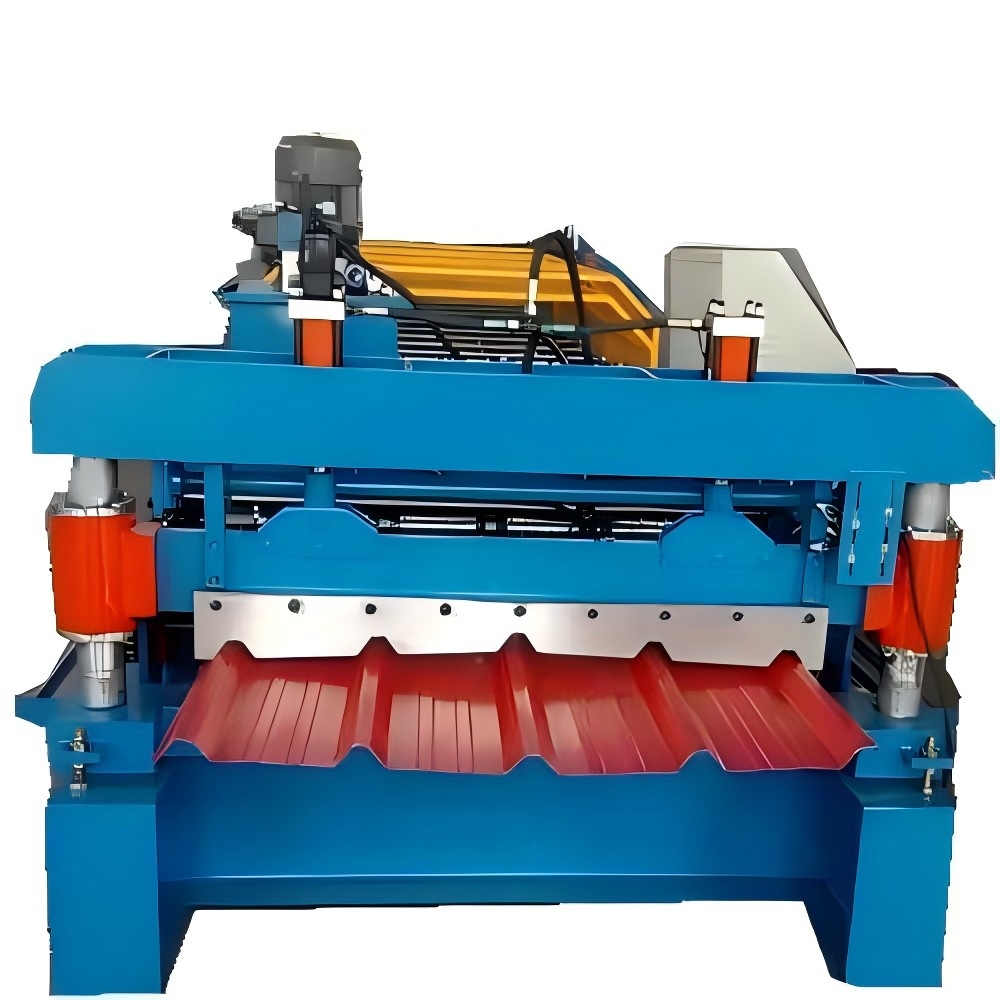

GBR roofers manufacture Box Profile Roofing Sheets from coil of flat coated steel which are processed through a roll forming machine. The machine is able to form any length and thickness of sheets.

Box profile is a modern alternative to corrugated metal sheets, which effective cover width is 1000mm. It also has a capillary groove down one edge which eliminates the need for using sealing strips and is proof.

Here are drawing profile and finished products:

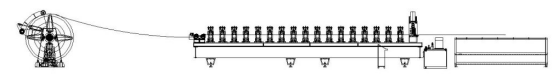

Layout of Metal Box Profile Roofing Sheet Rolling Machine

Uncoiling– Feeding and Guiding– Roll Forming– Cutting Off– Collecting.

Metal Box Profile Roofing Sheet Rolling Machine

Automatic Hydraulic Uncoiler

Hydraulic uncoiler is for holding and driving the steel coil. The uncoiler allows for a quick change of steel coli with minimal manual labor. The uncoiler is powered with a feedback system that ensures the roll former is not required to turn the coil. And the uncoiler will turn as required to reduce the potential for over coiling.

Roll Forming Machine

Coil Material: GI, PPGI, SS, HR, CR. 235-550MPA

Thickness range: 0.2-0.8mm

Line Speed : 15-20m/min

Main motor power: 7.5KW

Machine Voltage, Frequency, Phase:440 V, 50 Hz, 3Phase

Roll station: 20 stations

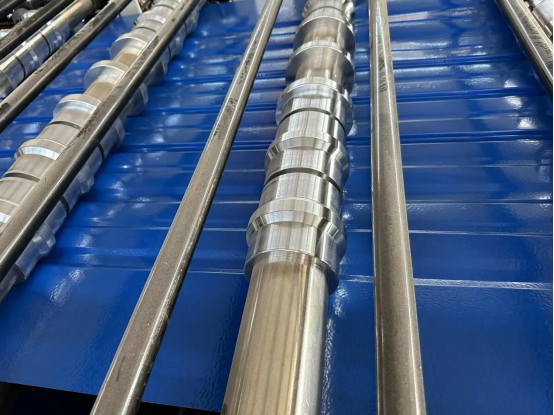

Roller material:ASTM 1045 chrome plated surface with hardness 58-62 degree ,CNC,

Shaft diameter: ¢76mm material: ASTM1045 with quenching and tempering

Transmission: by chain

Machine base frame adopt H beam welding steel

Machine chromed pillar as the stands

To avoid accidents,all of drive part adopt protect cove

Cutoff Unit

Cutting type: hydraulic, connect with the punching hydraulic unit

Cutting power by hydraulic, 5.5KWAC motor

Hydraulic working pressure: 12-16Mpa

Cutting after forming: Cut the sheet before roll forming to required length

Cutting motion: The roll forming part is NON-stop when cutting

Material of blade:Cr12 with heat treatment

Length measuring: Automatic encoder length measuring, brand: Omron

Tolerance of length: +/- 1.5mm each piece end product

Controlled Box

Programmable setting of profile dimensions: to be provided

Programmable cutting unit, various lengths in one programming cycle without quantity restrictions (without stopping the operating equipment)

Automatic stopping of the equipment after completion of the cutting program

Operating system language: English and Chinese.

Voltage, Frequency, Phase: 415 V, 50 Hz, 3Phase

Length inaccuracy can be amended easily.

Control panel: Button-type switch and touch screen

Unit of length: millimeter (switched on the control panel)