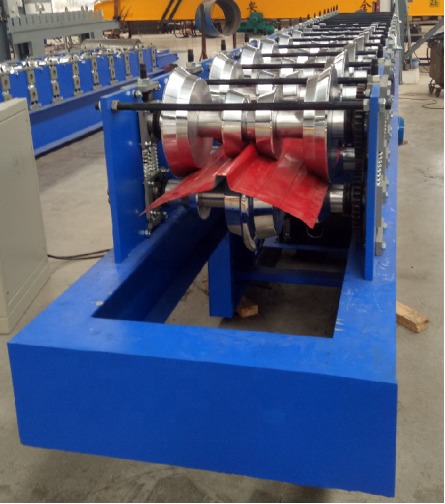

Description:Roofing ridge forming machine to make ridge cap suitable for steel roofing sheet top.Your ridge can be designed here.

Here are some popular ridge machines for your reference, stop to cut machine, working speed about 12-15m/min, non stop to cut machine, working speed about 20m/min.

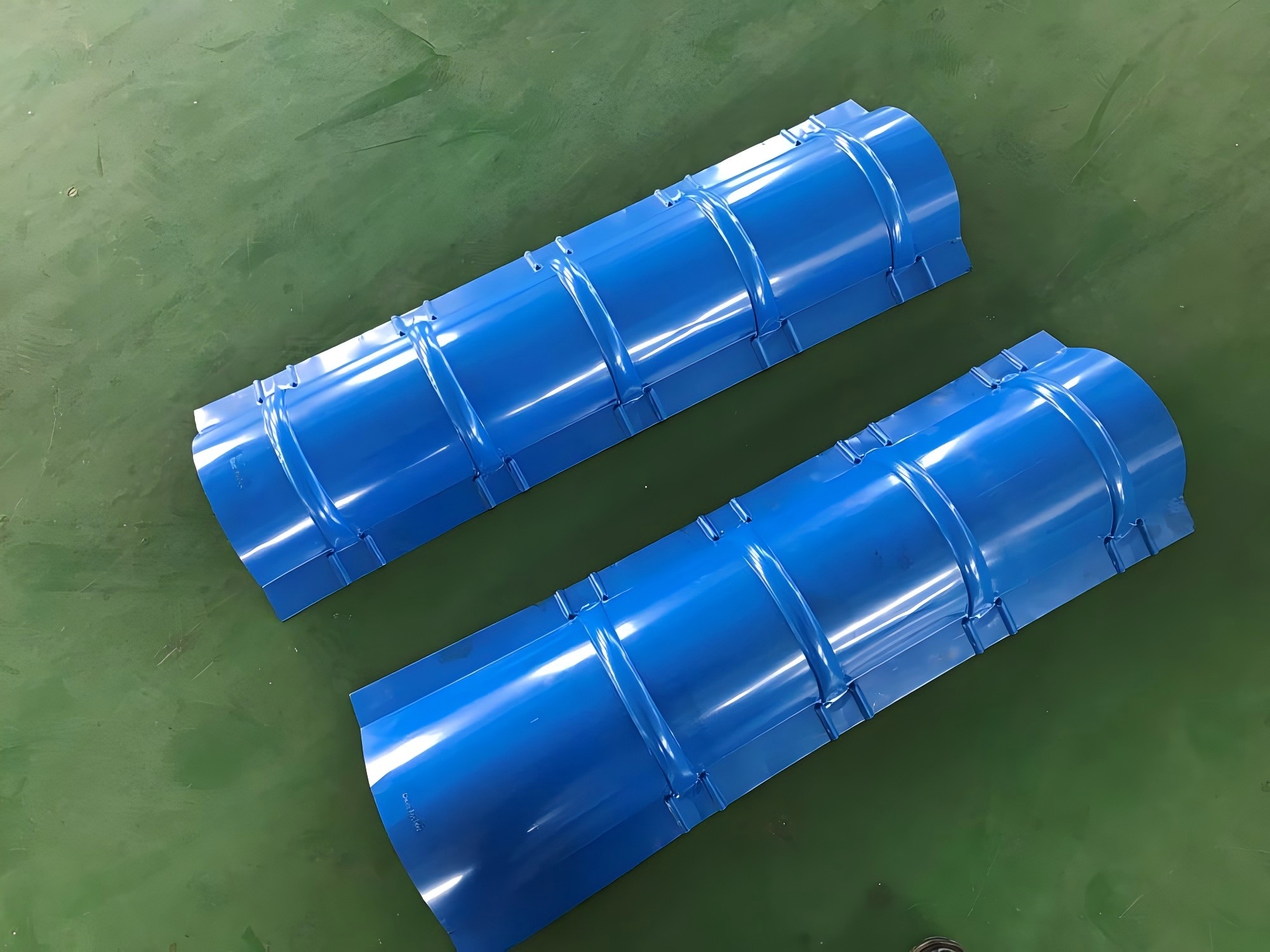

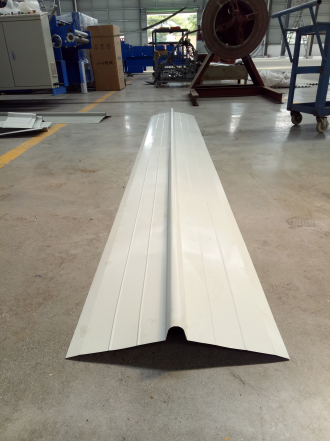

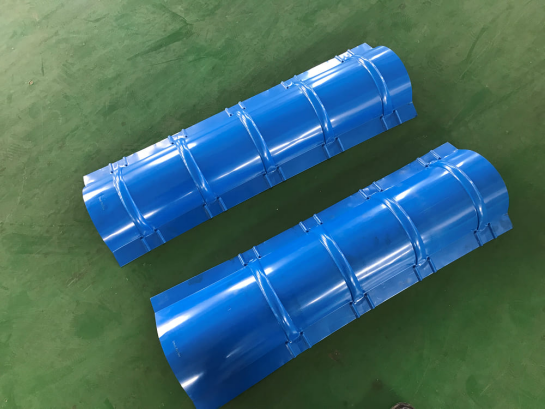

Standard ridge with flat leg, which need to cut the leg according to roofing trapezoidal sheets during installing/special ridge cutted according to roofing trapezoidal sheets, which can easily attached on roofing without futher cut during installing, which improve work efficiency greatly, and make great match to roofing sheets to water proof.

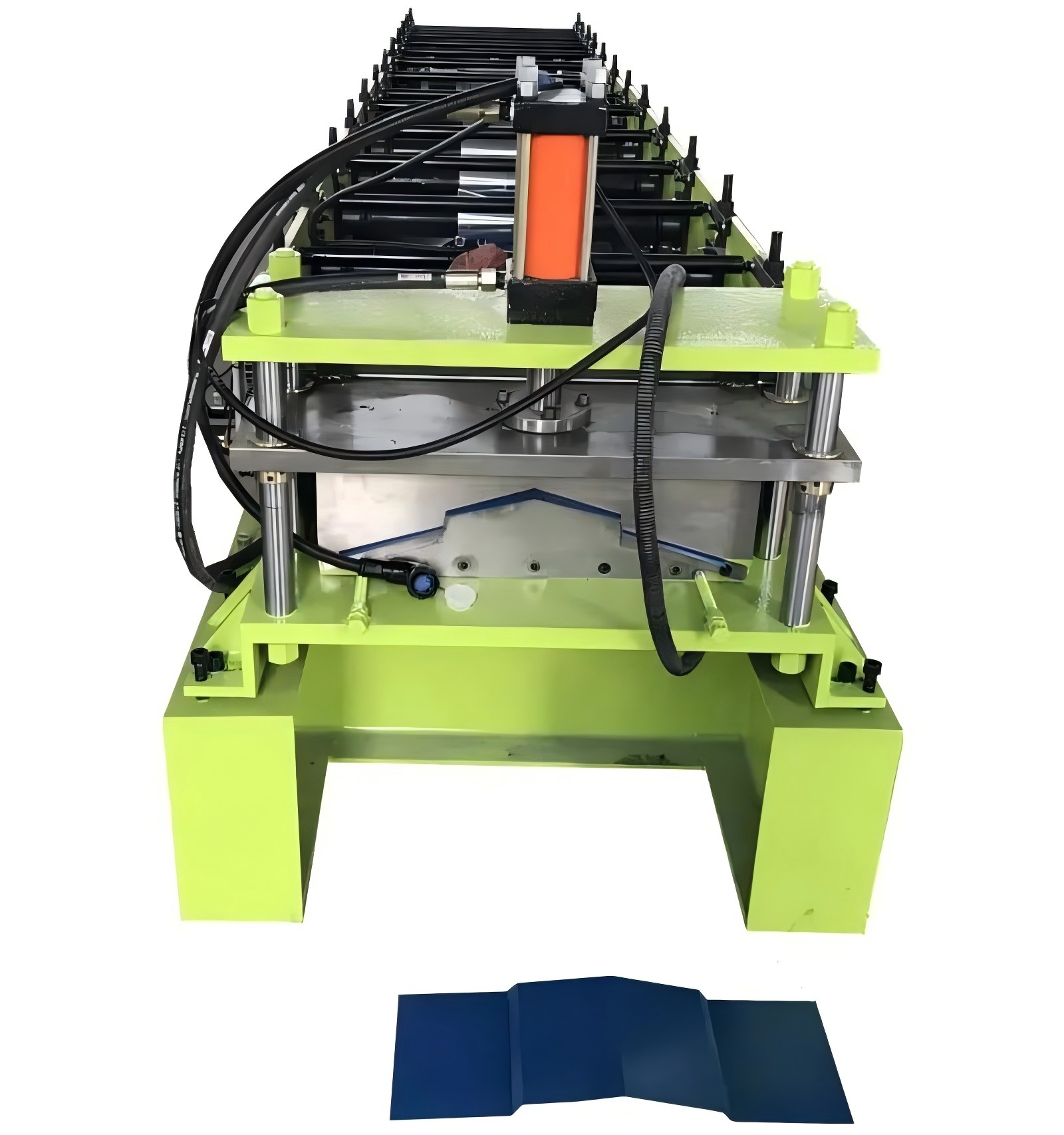

Ridge Capping Profile Rolling Machine

Ridge Capping Profile Rolling Machine is a cost-effective and smart roll former for manufacturing various shapes of ridge cap profiles for the roofing system.You can buy a good quality roof bending machine.

Ridge flashing use for the apex joins of two sides of the roof.Roof flashing a necessary part of any profiled clad building provides a clean,maintenance free and weightless,and totally weatherproof finish to your roof and is cost-effective it is the labor-saving solution that is available and can enhance the aesthetics of any structure.Roof flashing fit primarily to maintain a watertight roof.Without a flashing fitted.Also,rainwater would run down the chimney,or the higher area of roof tiles,and just disappear into the house interior where the chimney rises through the roof.

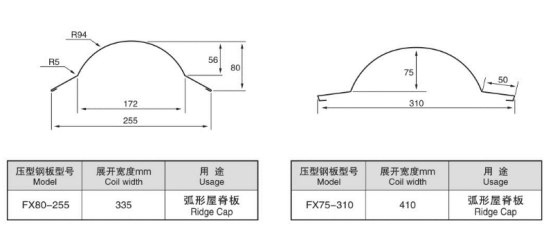

Here is one drawing profile and finished product:

Where the roof flashing used for?

Where a roof meets a vertical structure, there are natural weaknesses, including areas of discontinuity like joins and penetrable sections. If not properly sealed, these all become entry points for moisture.Roof flashing is used to connect these areas.

Zhongtuo Machinery can make a Economical and high quality roofing flashing machine, the machine size is small , it can’t take up so much factory space, the production speed 15-20m/min. The max speed we can design up to 55m/min, that will be a fully automatic high speed machine.

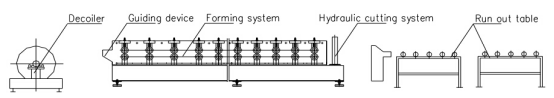

Processing Flow

Ridge Capping Profile Rolling Machine

The Advantage of the Machine:

1.Superior Quality Ridge Caps: The Ridge Cap Roll Forming Machine utilizes advanced technology to produce ridge caps of exceptional quality. With precise measurements and consistent shaping, it ensures that every ridge cap fits perfectly, providing a seamless and professional finish to any roof.

2.Time and Cost Efficiency: By automating the ridge cap production process, the roll forming machine significantly reduces labor costs and saves time. With its high-speed operation, it can produce a large quantity of ridge caps in a short period.

3.Customization Options: The roll forming machine offers versatile customization options, allowing you to create ridge caps tailored to specific roof designs and architectural preferences. From different profiles to various materials, you can effortlessly adjust the machine settings to achieve the desired results.

4.Durability and Weather Resistance: Ridge caps produced by the roll forming machine are built to withstand various weather conditions. The precise roll forming process ensures the creation of sturdy ridge caps that can effectively protect the roof from water infiltration, wind damage, and other environmental factors.

5.Easy Installation: We weld the hydraulic station with the machine, so you do not need to connect lots of pipes and wires. So it is easy for installation. In addition, each group of wires has corresponding markings for easy installation.

Ridge cap is widely used in various industrial plant, building, warehouse and simple steel structure constructure roofing system.

It used to connect the top between the two face of the roofing sheet.

This kind of ridge cap is usually matched with glazed tile on roofing system.

Here show you two kinds Kenya popular ridge cap profile drawing for your reference:

We support customized all kinds of profile. If you have drawing, pls send me. We will provide the best machine solution for you.

The machine use hydraulic cutting type, stable working, and the machine structurer is very durable, no easy deformation.

Before roll forming, the machine matched with pre-cutter to help cut off the material if you want to change to produce different colour and thickness.

The machine we use PLC system to control production quantity, speed and length.

That means you can use one machine to produce any length and quantity you want.

The PLC control system has aviation plug in it, just need plug in it, installation will be very easy, all of wires marked very clear.

PLC and frequency we use Delta brand, high quality no easy broken. Also can customized the electric part brand as your request.

All buttons on PLC use Schneider, counter use Omron brand. And have touch screen to easy operate.