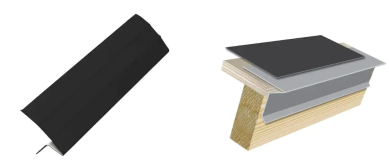

Description:A roof eave drip edge is an essential component of any roofing system. It is a metal strip that is installed along the edges of the roof to prevent water from seeping into the underlying structure. To efficiently produce these drip edges, a specialized machine called the Eaves Flashing Making Machine is used.

Eaves Flashing Making Machine

The Eaves Flashing Making Machine is a state-of-the-art equipment designed to manufacture high-quality drip edges with precision and efficiency. It is equipped with advanced technology and features that make the production process faster and more accurate. The machine is typically operated by skilled technicians who are trained in its operation and maintenance.

One of the key features of the Eaves Flashing Making Machine is its ability to form the metal strips into the desired shape. The machine is equipped with adjustable rollers and bending mechanisms that can accommodate different sizes and profiles of drip edges. This flexibility allows for the production of customized drip edges that perfectly fit the unique specifications of each roofing project.

Here is one drawing profile and finished product:

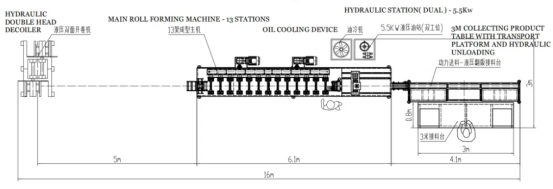

Work flow of the Eaves Flashing Making Machine:

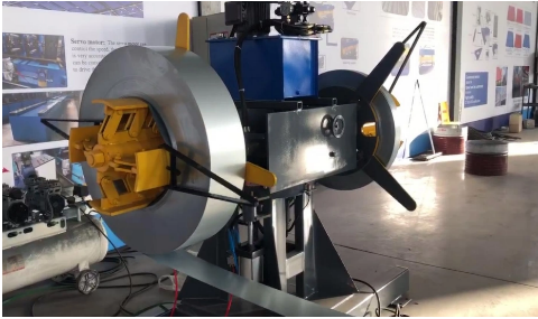

Eaves Flashing Making Machine

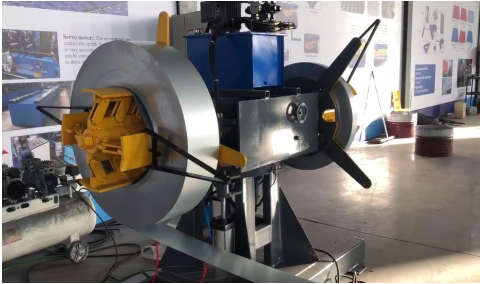

Automatic uncoiler with 2 coil's holder (each holder can load 1.5 tons coil)

a, Loading capacity: each side holder can bear 1.5 tons

b, Drive motor: 0.75 KW motor to drive the rolls moves rotary and 3 KW motor to get the trips tensioned

c, 4 pieces of arc plates as supporting arm to fix and adapt the inner of coils. they come to into a shape close to a circle, so that the material will not be badly deformed.

d, Max feeding speed: up to 100 meters per mintue

Rollformer

a, Frame of Steel Eaves Flashing Making Machine is made of cast iron stands,which are processed twice CNC tools

b, Shafts made of forged solid bar, material 45# steel and Fine lathing finished and cylindrical grinding, Quenching and tempering heat treatment to get good physical properties, No deformed after long term work.

c, Rollers made of high grade alloy steel Cr12, Twice CNC machined to get high precision & high frequency quenched with HRC 58-62 hard chrome plated & fine polished

d, Driven by gearbox transmission

e, Rugiing speed is up to 65-80 meters per minute

f,Flying shear with servo motor controlling system to guarantee the fast cutting and high-precision length cut

Electric Cabinet of the Eaves Flashing Making Machine

a,PLC,Inverter are adopted international brand, such as Siemens,Mitsubishi,Delta & Panasonic, and lower power components are Schneider brand

b, Motor is normally Chinese brand, but international brand is also available as per customization.

c, Wires are set in typically aviation plugs, convenient to get connected and more the installation more easier.

d, Encoder is OMRON brand

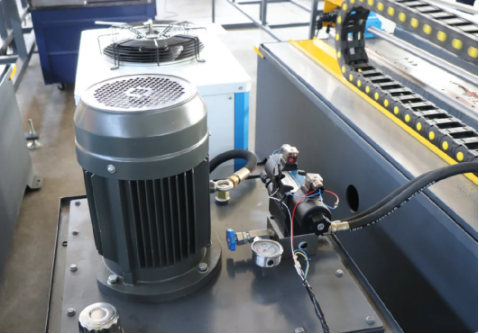

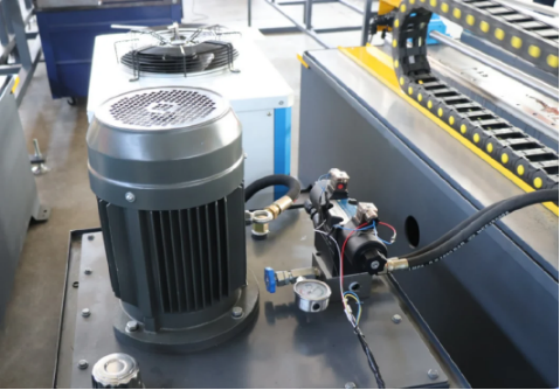

Hydraulic Station

a, A large power hydraulic pump is adopted, with tank that can fill into 280 liters oil. so that the pump supply good strength while keep natural temperature.Besides, a oil cooling machine is equipped to guarantee the pump output power stable for long time.

b, Solenoid valve is first class Chinese brand

Automatic Stacking Table

a,3 metters automatic stacking table with typical belt conveyor to match up with the drip edge rollformer's fast speed

b, 2 pushing poles are adopted, it is driven by hydraulic pump

c, semi-automatic baler machines are as option, we can change to simple manual table

The machine also has a cutting mechanism that can accurately trim the metal strips to the required length. This ensures that the drip edges are uniform in size and can be easily installed on the roof. Additionally, the machine can be programmed to produce drip edges with pre-set dimensions, further enhancing the efficiency of the manufacturing process.

Another advantage of using the Eaves Flashing Making Machine is its ability to work with various types of metal materials. Whether it is aluminum, steel, or copper, the machine can handle different thicknesses and strengths of metal, ensuring the production of durable and long-lasting drip edges. This versatility makes the machine suitable for a wide range of roofing projects.

In terms of safety, the Eaves Flashing Making Machine is designed with multiple safety features to protect the operators and prevent accidents. It is equipped with emergency stop buttons, safety guards, and sensors that detect any abnormalities in the operation. These safety measures ensure that the machine can be operated without any risks to the workers.

Overall, the Eaves Flashing Making Machine is a valuable tool in the roofing industry. It streamlines the production process, improves the quality of the drip edges, and enhances the overall efficiency of roofing projects. With its advanced technology and features, this machine has become an indispensable asset for roofing contractors and manufacturers worldwide.