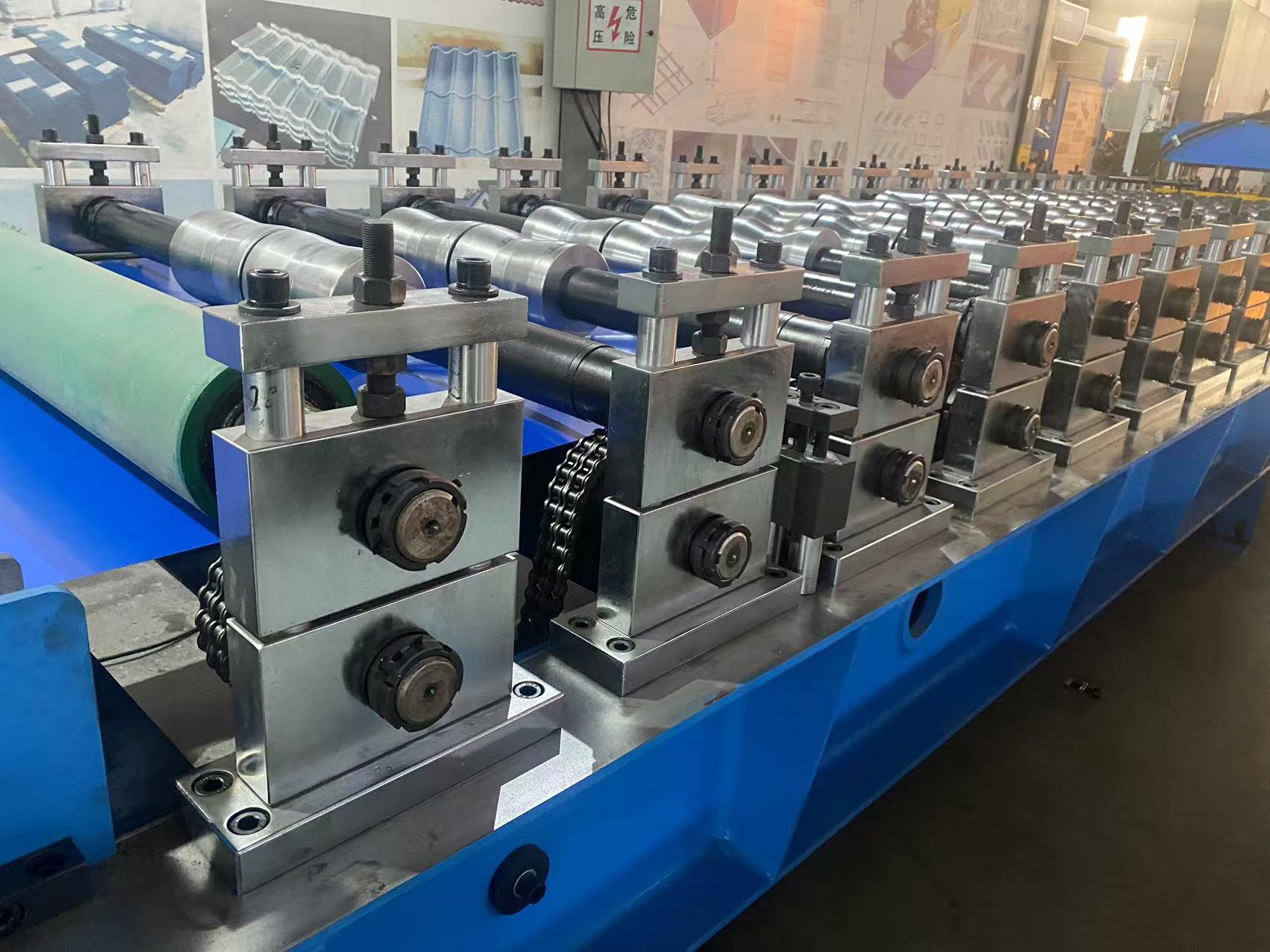

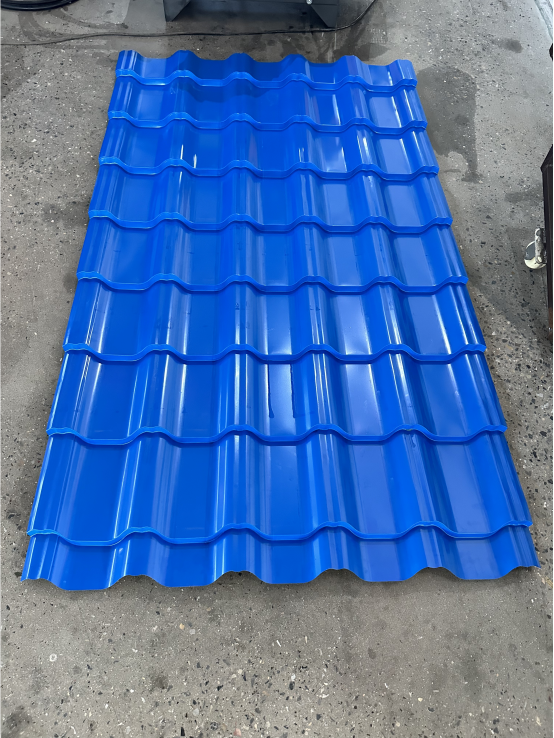

Description:The Glazed Sheet Roll Forming Machine for Versatile Metal Roof Tile Production is an advanced piece of industrial equipment designed to efficiently create metal roof tiles. This machine combines hydraulic cutting with roll forming technology to produce high-quality metal tiles used in various roofing applications.

High Working Speed Glazed Tile Roll Forming Machine

Best Price for Glazed Tile Roof Sheet Roll Former Machine is widely used in building: the steel-structured large-scale warehouses, plants, supermarkets, shopping malls, trade markets, stadiums, holiday villages, sanatoriums, hotels, villas, residences, and different kinds of greenhouses. What’s more, equipment can be designed and manufactured as customized requests.

Here are some profiles for your reference:

High Working Speed Glazed Tile Roll Forming Machine

Features

Hydraulic Cutting System:

Precision: The hydraulic cutting system ensures accurate cuts with clean edges, reducing waste and improving the quality of the final product.

Durability: Hydraulic components are built to last, providing reliable performance over long periods of operation.

Roll Forming Technology:

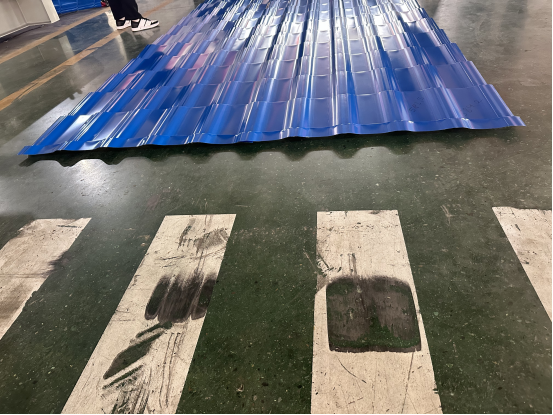

Efficiency: The roll forming process allows continuous production of metal roof tiles, significantly increasing productivity compared to traditional methods.

Consistency: This technology ensures uniform thickness and shape of the tiles, maintaining high standards of product quality.

Cost-Effective:

Energy Efficiency: The machine is designed to use less energy, reducing operational costs.

Low Maintenance: Built with high-quality materials and components, the machine requires minimal maintenance, further lowering operational expenses.

Versatility:

Multi-Profile Capability: The machine can be adjusted to produce different profiles and shapes of roof tiles, catering to various design requirements.

Material Flexibility: It can handle a range of materials, including steel, aluminum, and other metals, making it suitable for diverse roofing projects.

Automation and Control:

User-Friendly Interface: Equipped with an intuitive control system, the machine is easy to operate, allowing quick adjustments and settings.

Automation: Features automated feeding, cutting, and stacking, reducing the need for manual intervention and increasing efficiency.

Benefits

High Productivity:

Capable of producing a large volume of metal roof tiles in a short time, meeting high-demand requirements.

Quality Assurance:

Ensures consistent product quality with precise cutting and forming processes, leading to high customer satisfaction.

Cost Savings:

Low energy consumption and minimal maintenance reduce overall production costs, making it a cost-effective solution for manufacturers.

Flexibility:

The ability to produce various tile profiles and use different materials makes this machine adaptable to changing market needs and customer preferences.

Durability:

Robust construction and reliable components ensure long-term operation with minimal downtime, enhancing overall productivity.

Applications

Residential Roofing:

Ideal for producing metal roof tiles for houses and apartments, providing durable and aesthetically pleasing roofing solutions.

Commercial Buildings:

Suitable for creating roof tiles for commercial structures such as offices, shopping centers, and warehouses.

Industrial Facilities:

Used in manufacturing roof tiles for factories and other industrial buildings, offering strong and long-lasting roofing options.

Agricultural Structures:

Produces metal roof tiles for barns, sheds, and other agricultural buildings, ensuring protection against harsh weather conditions.

Renovation Projects:

Perfect for creating custom tiles for renovation and restoration projects, allowing for precise matching of existing roofing styles.

Machine Parameters

Item | Value |

Driving Motor | 15KW*2 |

Forming Station | 20 |

Roller Material | GCr15 |

Shaft Diameter | 75/105mm |

Shaft Material | 45# steel |

Pump Motor | 7.5KW |

Frame Type | Common weld wall |

Cutting Type | Hydraulic Cutting |

Control System | PLC |

Main Electric Parts Brand | Simenz, Delta, Omron or Schneider |

Cutting Length Precision | ±2mm |

Machine Dimension | 10500*1520*1750mm |

Electric Standard | 380V/50HZ/3Ph or customized |

Paint Color | Grey White+bule or customized |