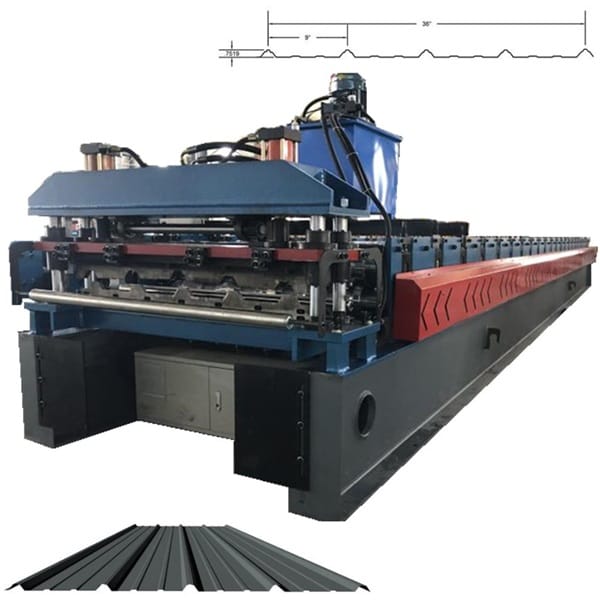

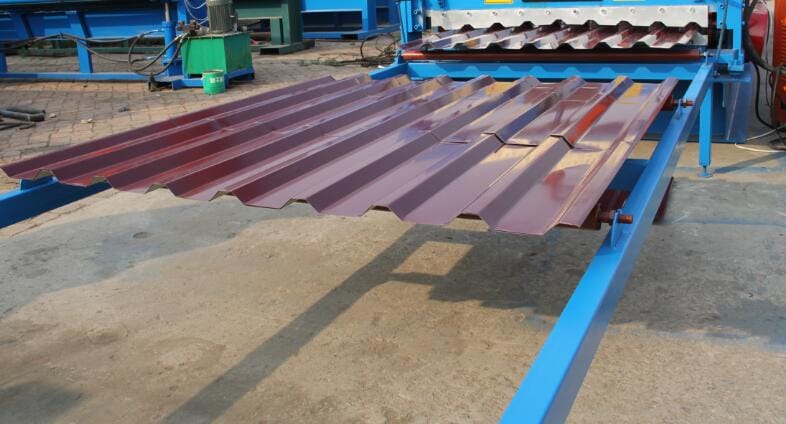

36" cover width trapezoidal roofing sheet L5 panel roll forming machine

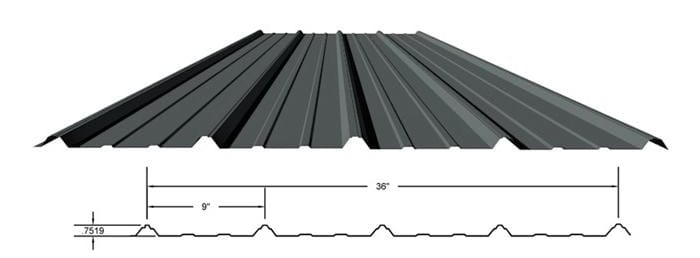

36" cover width trapezoidal roofing sheet L5 panel is popular type in USA market. The profile drawing as below.

Tecnnical Parameter

Series | Details | Parameter |

Product sheet | Raw material | Color coated/Galvanized mild steel |

Material thickness | 0.3-0.8 mm | |

Feeding width | 1050 mm | |

Effective width | 914 mm | |

Sheet cutting length | Adjustable |

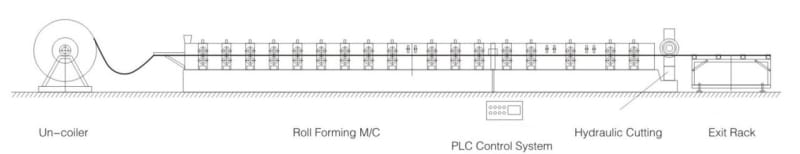

The Work Flow of the forming production line

Roll Forming Machine Feature

1.Control system support multi orders input.

2.Steady working condition and low failure rate to improve the production.

3.Simple installation and maintainence.

5T Decoiler

Decoiler | Work type: passive type |

Structure: Steel channel welded for the basic frame | |

usage:To support the coil and make the uncoiling | |

Loading capacity: 5 tons | |

Inner diameter: 450-550mm (manual adjustment) | |

Coil width: 1050mm | |

Brake system: manual brake |

The Main Forming Machine

Roll forming machine | Feeding device | One set guiding roller |

Steel plate welded platform to carry the sheet and feed into roll forming system | ||

Feeding width is adjustable with the handle wheels | ||

Rolling shaft

| Shaft material:45# STEEL | |

Shaft diameter: 80mm | ||

Tempering treatment to prevent deformed and improve hardness | ||

Roller

| 45# steel | |

Chromed treatment, improve the hardness and prevent abrasion, anti corrosion increase of service life | ||

Rolling station | 16 rolling stations | |

Work speed | 0-15 m/min | |

Machine structure | 20mm Steel plate welded structure | |

Machine basic frame | 350# H steel welded | |

Work power | 5.5 kw | |

Rolling spacer | Anti rusty treatment | |

Pull rod | Anti rusty treatment | |

Transmission | By Chains with cover | |

Noted: please fill the lube in case the chains getting dry |

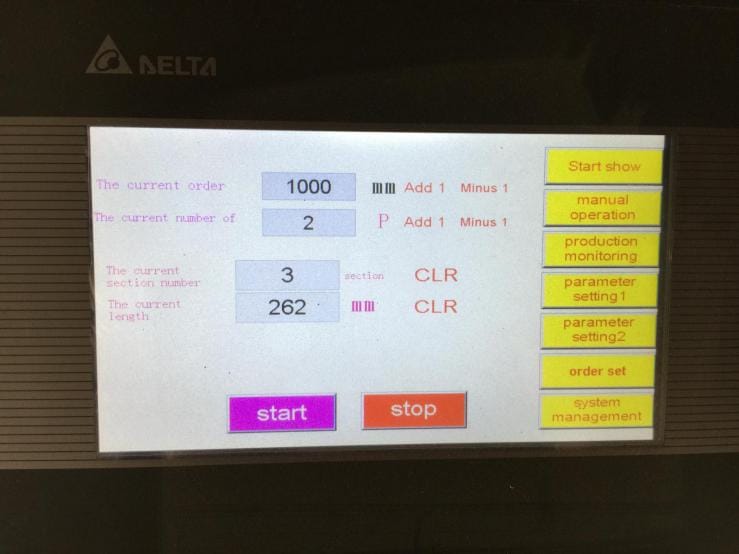

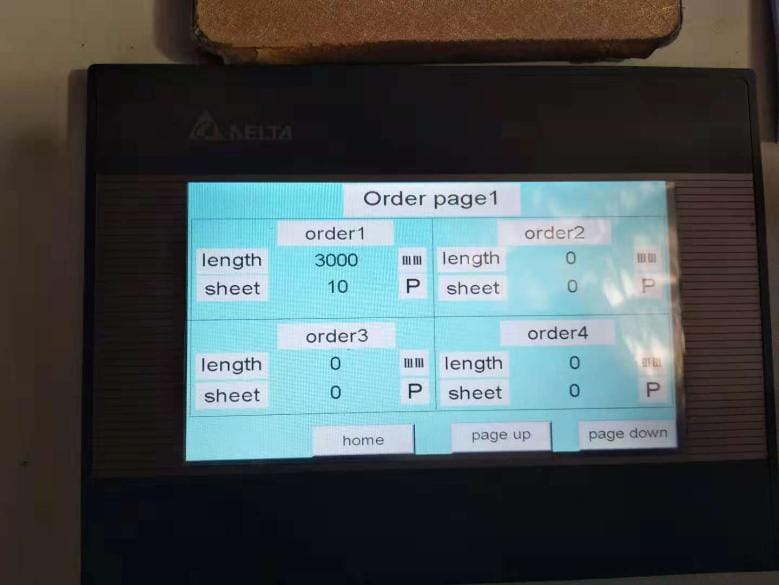

PLC Control System

Control system | Frequency brand | Delta (original) |

PLC brand | Delta (original) | |

Frequency brand | Delta (original) | |

Screen type | Touch screen, also have buttons on the panel | |

Screen language | English/Chinese | |

Cut command | Yes | |

Profile length set-up | Yes | |

Batch quantity program | Yes | |

Low pressure electric part | Schneider brand | |

Encode | Omron brand | |

Tip | please do the waterproof and damp proof work well if the machine is not used for a long time | |

Please restart the machine and try all the functions each two weeks, to prevent the electrical parts getting aging | ||

Remark | Support multi orders input,ensure the machine can work continuously according to different request without stop | |

All the electrical parts are branded with a high quality, it can be fixed easily if damaged. Because you can find these again in any area of the country and it’s a standard parts. |

Hydraulic Cutting System

Cutting system | Work type | Hydraulic cutting |

Driving method | By pillar type Cylinder | |

Cutting device structure | Pillar type | |

Noted: please fill the lube before start the machine the first time | ||

Hydraulic motor power | 4.5 kw | |

Hydraulic oil | Hydraulic oil number: 46# | |

Quantity: around 100 Litre | ||

Maintain: change the hydraulic oil every 2 years | ||

Cooling method | Equipped with fan on the tank, in case the oil temperature getting hot when the machine working for hours continuously, ensure the hydraulic oil in a constant temperature to have enough power for cutting device | |

Cutter material | GB-Cr12 with heat treatment | |

Cutting length tolerance | ±1mm/3m | |

Cutting feature | Steady and safe working condition | |

Oil tube and wires connection | All the tubes and wires will be marked by the numbers or letters, So that it will be very easy to connect for the new. |

Receiving Table

<td width="176" valign="top" style="padding: 0px 7px; border-left: none; border-right-width: 1px; border-right-color: windowtext; border-top

Product table | Length | 3 meters |

Width |

|