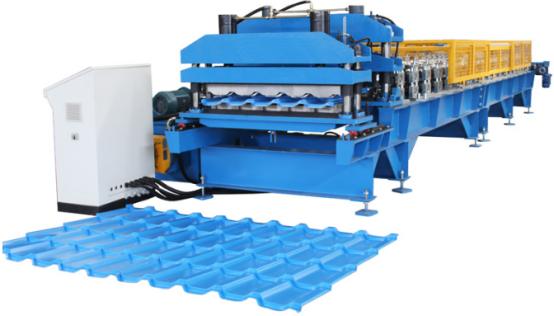

Description:Roof Tile Forming Machine adopts steel coils as material and gets roofing sheets after the process of uncoiling, feeding, roll forming, cutting into length and output with table. Whole machine adopts PLC controlling, AC frequency speed regulating to fulfill the automatic production, which is very suitable for the metal cold rolled processing industry.

Glazed Tile Roof Roll Forming Machine

A glazed tile forming machine is an essential piece of equipment in theconstruction and roofing industries, specifically designed to produce highquality, aesthetically pleasing glazed tiles. These machines operate by automatically feeding and pressing metal sheets into desired profiles,replicating the appearance of traditional clay tiles while offering enhanced durability and weather resistance. The production process is characterized by its precision, speed, and efficiency, making it suitable for large-scale manufacturing. Equipped with advanced features like hydraulic cutting systems, programmable controls, and automated decoilers, glazed tile forming machines ensure consistent product quality and significantly reduce manuallabor and production time. Consequently, they are a vital asset for manufacturers seeking to meet the growing demand for reliable, visually appealing roofing materials.

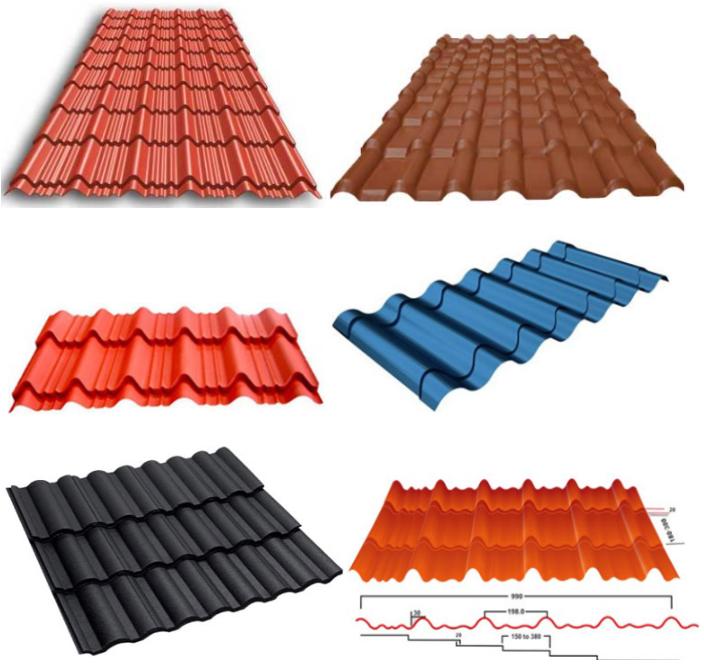

Here Are Some Drawings Profile For Your Reference:

Glazed Tile Roof Roll Forming Machine

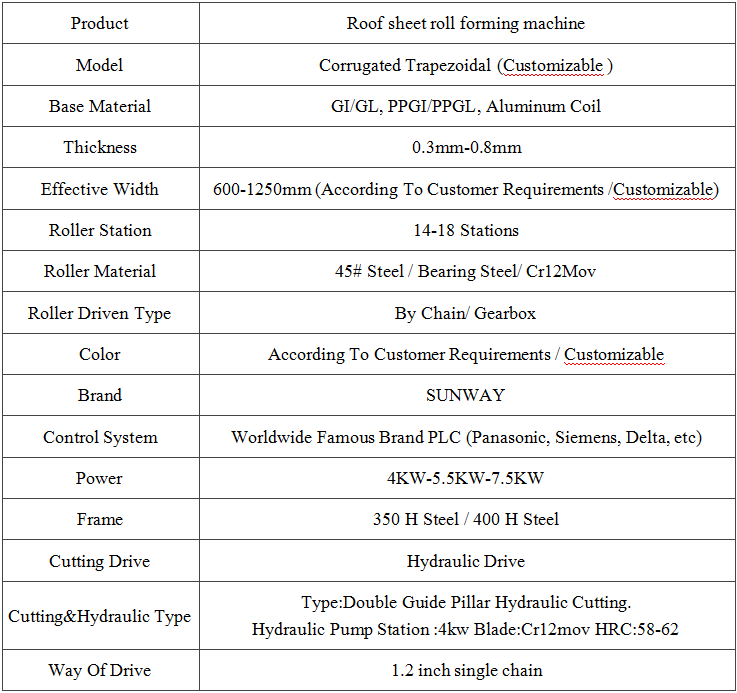

Roof Tile Forming Machine Parameters

Functionality and Process

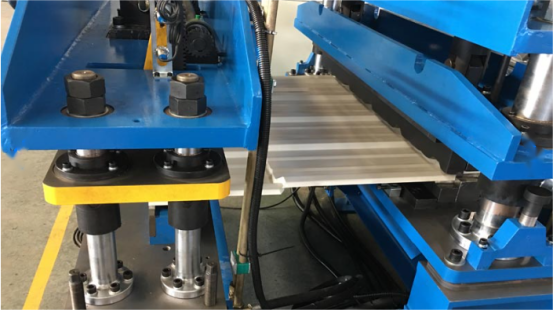

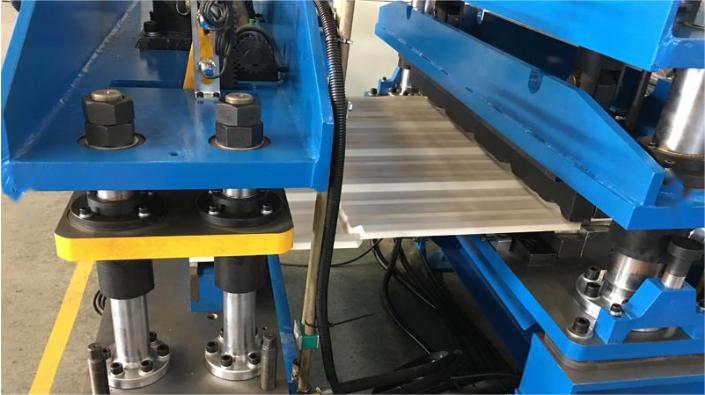

The machine operates by continuously feeding metal coils through a series of precisely engineered rollers and dies. These rollers shape the meta into the desired profile, forming the distinctive design characteristic of glazed tiles, The process involves roll forming the metal sheets while simultaneously applying a protective coating or glaze, typically made of materials like ceramic or enamel. This coating enhances the tile's durability, weather resistance, and aesthetics.

Features and Capabilities

Glazed tile roll forming machines are versatile, capable of producing various tile profiles, shapes, and sizes to meet diverse architectural and design requirements. They accommodate customization options, allowing for different tile lengths, widths, and surface textures. Additionally, these machines offer flexibility in creating tiles with different color variations, catering to the preferences and specifications of construction projects.

Advantages in Construction

The use of roof tile roll forming machines in construction offers numerous advantages. These tiles not only provide an attractive finish but also offer excellent durability, resistance to corrosion, and weatherproofing qualities. They contribute to the overall structural integrity of buildings while adding aesthetic value. Moreover, the high- speed and precision production capabilities of these machines ensure consistent quality and reduce material waste, making them a cost-effective solution for roofing and cladding needs.

Conclusion

In the construction industry, glazed tile roll forming machines stand as essential equipment for creating roofing and cladding materials that blend functionality with aesthetics. Their ability to produce high- quality, customized glazed tiles efficiently plays a vital role in ensuring durable and visually appealing building exteriors. As a result, these machines remain integral to the production process, meeting the demand for reliable, long-lasting, and visually striking roofing solutions in modern construction practices.