Corrugated Roofing Sheet Machine Corry Profile Roll Forming Machine

Corrugated sheets are typically used to span a roofing structure to provide cover or shelter, distinguished for their wavy design which gives the sheet rigidity along its length and prevents it from sagging between the supports. Corrugated sheeting can also be overlapped which often avoids the need for reducing the lengths by cutting. Waterproof and often impact resistant, corrugated roof sheeting is suitable for standard roofs, canopies, walkways, carports, and many other structures.

Zhongtuo corrugated roofing sheet roll forming machine is designed to produce corrugated sheets in batch automatically.

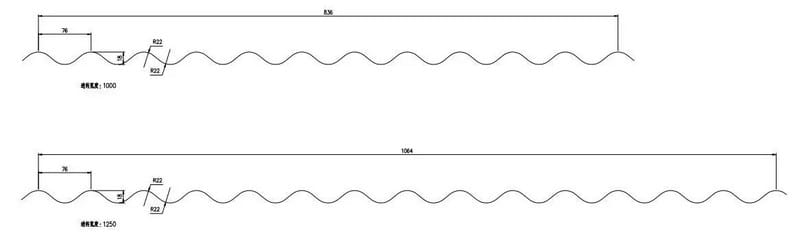

The profile drawing provided by customer

Finished Product

Series | Details | Parameter |

Product sheet | Raw material | Galvanized sheet or PPGI |

Material thickness | 0.3-0.8 mm | |

Feeding width | 1000 mm,1250mm | |

Effective width | 836 mm,1064mm | |

Sheet cutting length | Adjustable |

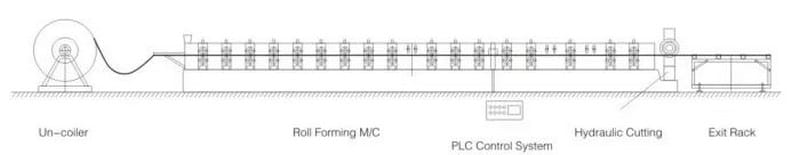

The Work Flow of Roll Forming Machine

5T Manual Un-coiler

Decoiler | Work type: passive type |

Structure: Steel channel welded for the basic frame | |

usage:To support the coil and make the uncoiling | |

Loading capacity: 5 tons | |

Inner diameter: 450-550mm (manual adjustment) |

The Main Roll Forming Machine

Roll forming machine | Feedingdevice | One set guiding roller |

Steel plate welded platform to carry the sheet and feed into roll forming system | ||

Feeding width is adjustable with the handle wheels | ||

Rolling shaft | Shaft material:45# STEEL | |

Shaft diameter: 80 mm | ||

Tempering treatment to prevent deformed and improve hardness | ||

Roller | 45# steel | |

Chromed treatment, improve the hardness and prevent abrasion, anti corrosion increase of service life | ||

Rolling station | 17 rollingstations | |

Work speed | 0-15m/min | |

Machinestructure | cast iron archway structure | |

Machinebasic frame | 500# H steel welded | |

Work power | 7.5 kw | |

Rolling spacer | Anti rusty treatment | |

Pull rod | Anti rusty treatment | |

Transmission | ByChains with cover | |

Noted: please fill the lube in case the chains getting dry |

PLC Control System

Control system | Frequency brand | Delta |

PLC brand | Delta | |

Screen type | Touch screen, also have buttons on the panel | |

Screen language | English/Chinese/Spanish | |

Cut command | Yes | |

Profile length set-up | Yes | |

Batch quantity program | Yes | |

Low pressure electric part | Schneider brand | |

Encode | Omron brand | |

Tip | please do the waterproof and damp proof work well if the machine is not used for a long time | |

Please restart the machine and try all the functions each two weeks, to prevent the electrical parts getting aging | ||

Remark | Support multi orders input,ensure the machine can work continuously according to different request without stop | |

All the electrical parts are branded with a high quality, it can be fixed easily if damaged. Because you can find these again in any area of the country and it’s a standard parts. |

Cutting System

Cuttingsystem | Work type | Hydrauliccutting |

Driving method | Bypillar type Cylinder | |

Cutting device structure | Pillar type | |

Noted: please fill the lube before start the machine the first time | ||

Hydraulic motor power | 3kw | |

Hydraulic oil | Hydraulic oil number: 46# | |

Quantity: around 100 Litre | ||

Maintain: change the hydraulic oil every 2 years | ||

Cooling method | Equipped with fan on the tank, in case the oil temperature getting hot when the machine working for hours continuously, ensure the hydraulic oil in a constant temperature to have enough power for cutting device | |

Cuttermaterial | GB-Cr12with heat treatment | |

Cutting length tolerance | ±1mm/3m | |

Cutting feature | Steady and safe working condition | |

Oil tube and wires connection | All the tubes and wires will be marked by the numbers or letters, So that it will be very easy to connect for the new. | |

Remark | If the production quantity is large, we suggest the client prepare the one set spare cutter, the spare cutter will cost USD280 one set, the original cutter can be grinding then use again. It’s better that stop the machine for 30minutes every 4-5 hours, if the temperature is high. If the weather is cold, please start the pump first for 5 minutes to heat the hydraulic oil, then do the cutting work. |

The Hydraulic Station with cooling system

<p style="margin-top:0;ma