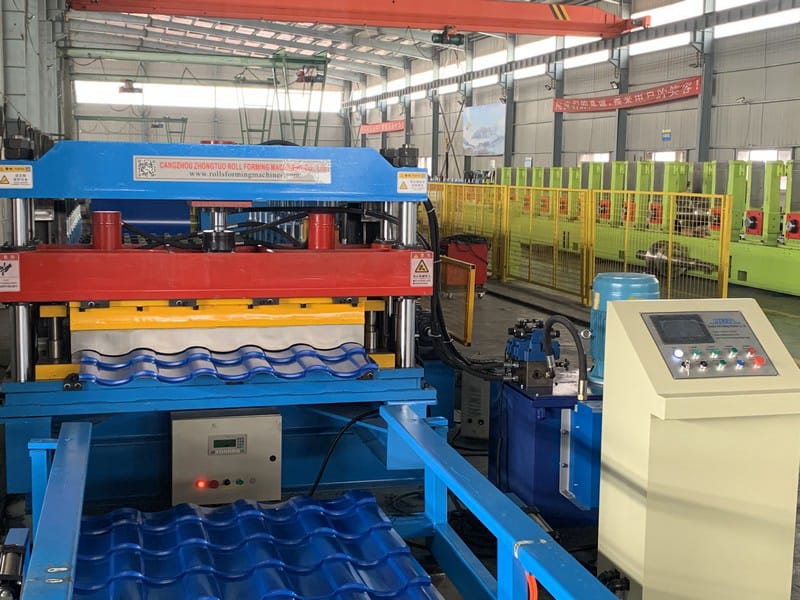

Automatic Colour Glazed Tile Metal Steel Roof Panel Roll Forming Machine

Automatic Colour Glazed Tile Metal Steel Roof Panel Roll Forming Machine is for making the roofing sheet with 3D effect.Which is very good look use on the roof.

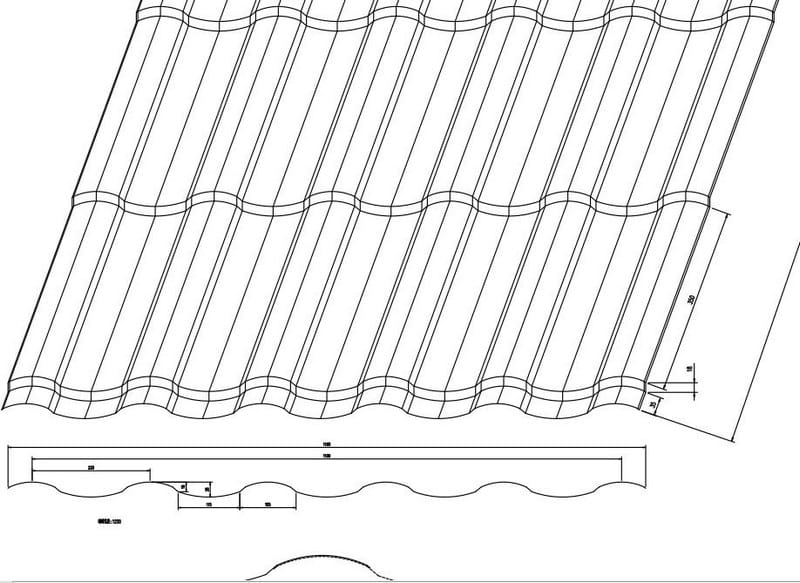

Here one profile drawing and finished products show you.(Or ypou want produce other shapes roofing sheet can show me,as customized)

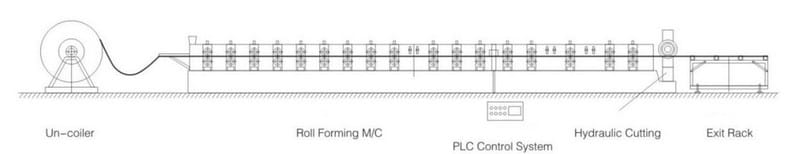

Working flow of Glazed roofing sheet producing line:

Uncoiling---feeding device---main roll former---hydraulic press and cutting---product collect table

Main Elements of Glazed roofing sheet producing line:

Series | Quantity | Remark |

Manual decoiler | 1 set | 5 tons |

Roll forming machine | 1 set | By chains drive |

Hydraulic system | 1 set | Press step andcutting |

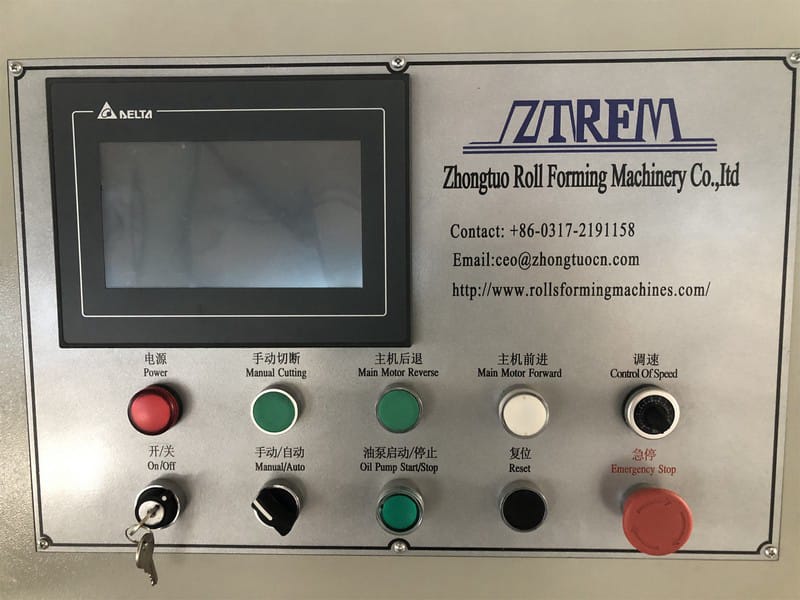

PLC control system | 1 set | |

Product receiving table | 1 set | 3 m automatic stacker |

Main parameters of Automatic Colour Glazed Tile Metal Steel Roof Panel Roll Forming Machine:

Coil thickness | 0.3-0.8mm |

Roller shaft | 75mm |

Roller station | 13 station |

Motor | 5.5kw |

Frame | 300 channel beam |

Driver | 1 inch |

Working speed | 0-10m/min |

Roller material | 45# heat treatment |

Machine style | ERU style |

Length | 7.5m |

hydraulic station | 4.5kw |

PLC control | With touch screen Delta brand for good using |

Delivery time | with 45 days |

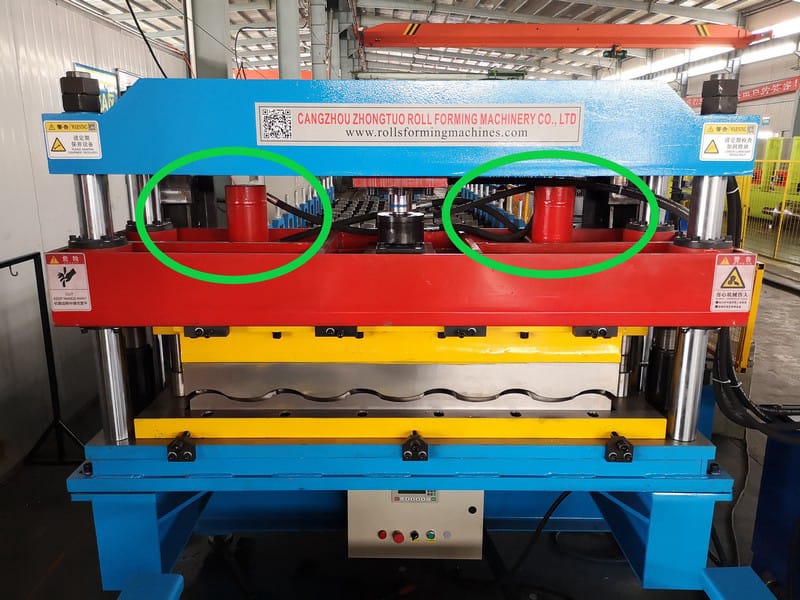

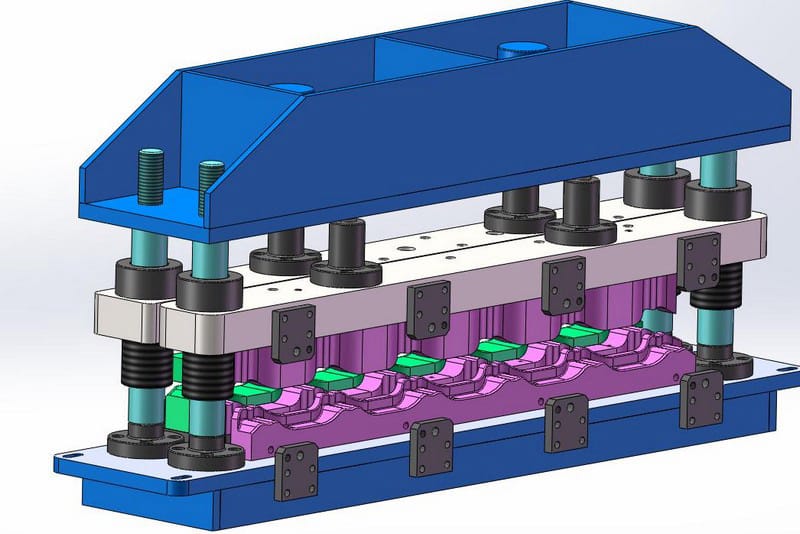

The hydraulic cutting system we use two guide pin cylinder, provide more hydraulic power to the cutting.

The technical of Automatic Colour Glazed Tile Metal Steel Roof Panel Roll Forming Machine,especially on the cutter.

Advantage details:

1. A glazed tile conformal cutter, which is characterized by comprising a cutter holder, the upper part of the cutter holder is provided with an oil cylinder, the end of the piston rod extending from the lower end of the oil cylinder is provided with an upper knife beam, and the upper cutter.

2.The connecting plate is fixedly installed on the upper knife beam, and a lower cutting knife is correspondingly arranged below the upper cutting knife,the lower cutting knife is fixedly installed on the lower knife beam, and the lower knife beam is arranged on the cutting knife frame.

3.The structure of the blade can cut out the arc of the glazed tile according to the shape, and the edge can be controlled to 5 mm.It does not produce waste, so that the color steel plate can be used 100%

All of the rollers and roller shaft have quenched and chormed treatment, make the rollers more smoothly,improve the hardness and prevent abrasion, anti corrosion increase of service life.

Hydraulic station with cooling fan for long time using

PLC control cabinet use Delta touch screen and Schneider buttons for good quality.