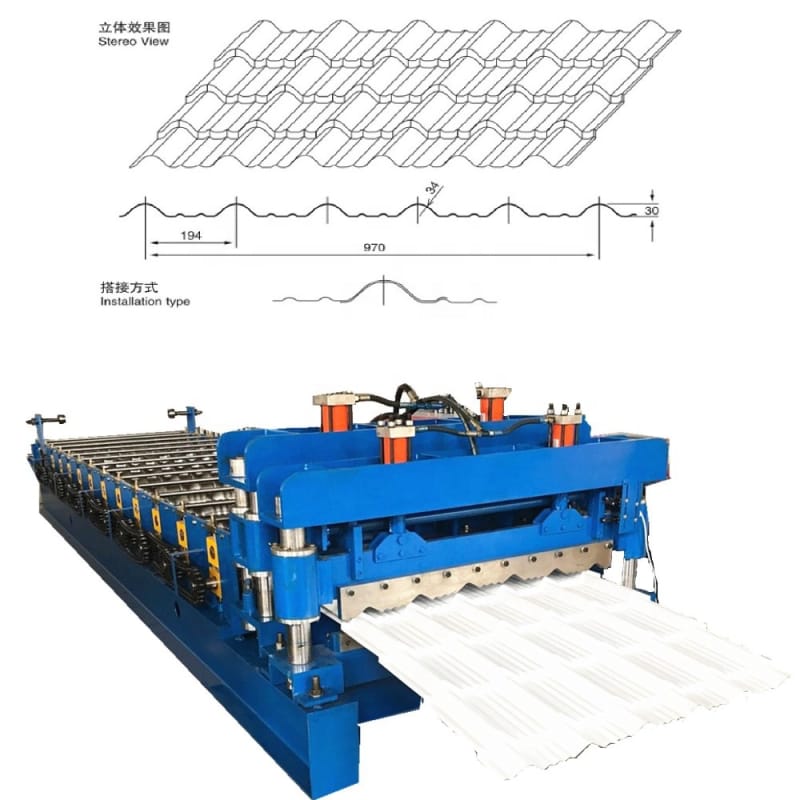

Glazed tile roofing sheet making machine metal step tile making machine

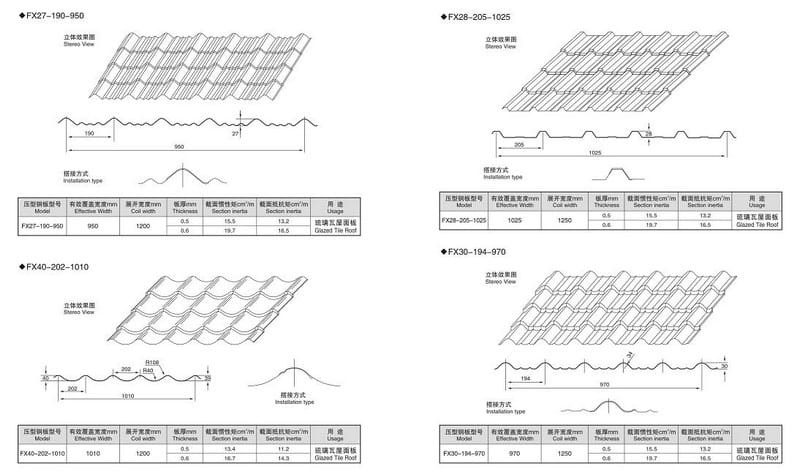

Glazed tile (also called step tile, metocoppo tile, corrugation tile etc) roofing sheet roll forming machine is a new generational type with high accurate and high-efficient, including decoiling system, feeding system, roll forming system, pressing system, cutting system, auto-stacker system, hydraulic system, PLC control system etc. Material thickness: 0.3-0.8mm Max, speed:5-8m/min. Here are some drawing profile for example:

The Glazed tile roofing sheet making machine allows you to produce many types and sizes sheet .The drawing profile is customized.One machine for any length and width sheet , it also can create 3D roofing effect.

Product parameter of Glazed tile roofing sheet making machine

Roofing glazed sheet producing line elements | ||

NO. | Item name | Quantity |

1 | decoiler(manual/hydraulic) | 1 set |

2. Main forming machine

| feeding device with manual broach | 1 set |

roll forming | 1 set | |

shearing system | 1 set | |

3 | Hydraulic Station | 1 set |

4 | PLC control system | 1 set |

5 | Runout table | 1 set |

6 | Spare parts: 1.Easy damaged parts: conk 2 pcs, fuse-link 4 pcs 2. Rubber mat 1 pcs; 3.Bolt spanner 1 pcs 4. One set of cutting balde

| |

What makes Zhongtou glazed tile making machine is different with other?

1. Each hydraulic part, we will use two hydraulic jack to make sure the shearing more powerful.

2. We use the pillar post as the shearing pole, it can add oil more easily.

3. All the rollers we will use the hard chroming, to make sure not damage the surface of the coil.

4. At the leveling part, we will add the filming system for the tile making machine.

5. And for the leveling part, we will manual cutter, hydraulic cutter or the others.

Related products

5 Ton hydraulic decoiler, 7 Ton hydraulic decoiler or 10 Ton hydraulic decoiler

Metal fully automatic stacker like 6 meters or 12 meters.