C8 C21 Roofing Sheet Double Layer Machine

C8 and C21 profiles both are popular roofing sheet in Russian market. These two profiles can be make by one double layer roofing sheet machine. Here I will show you more details information about C8 and C21 roof sheet making machine.

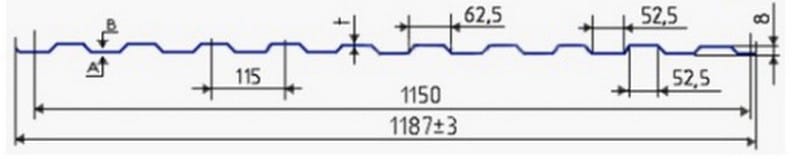

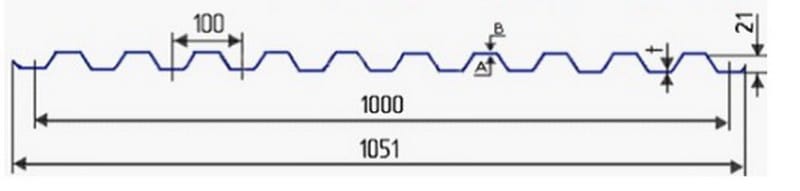

The Profile drawings

C8

C21

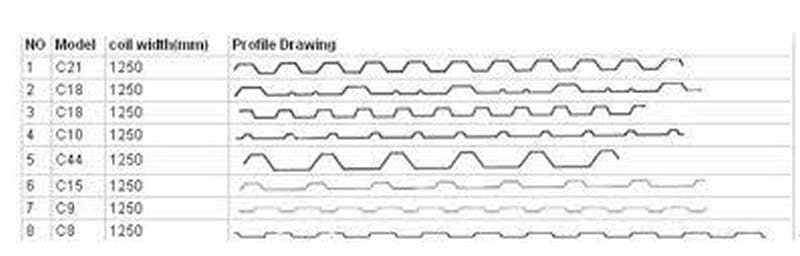

We also can customize the machine as your requirments to make more profiles as follows.

Product show C8

C21

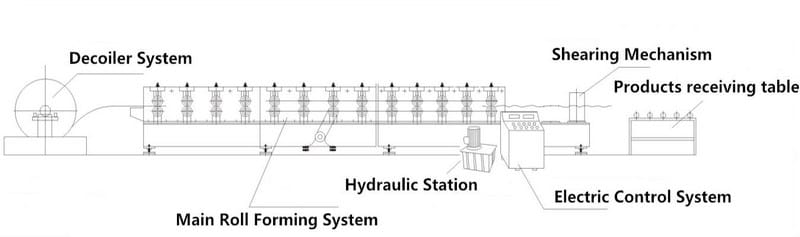

Work flow of C8 C21 Roofing Sheet Double Layer Machine

5T Manual Decoiler

Usage: It is used to support the steel coil and uncoil it in a turnable way. Passive uncoil pulled by roll forming system

Decoiler type: manual

Loading capacity: 5T

Uncoiling width: 1250mm

Inner diameter: 450-550mm

Quantity: 1 set

Usage: Put the raw material (steel plate) through the platform into the roll former and process, it can guarantee that the products are neat, parallel and everything is uniformity.

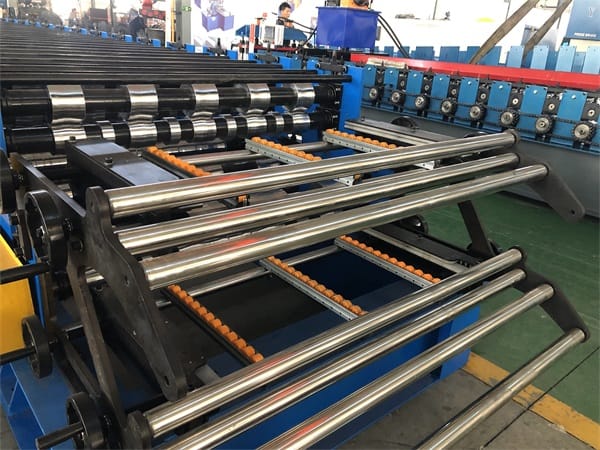

Main Roll Forming System of C8 C21 Roofing Sheet Double Layer Machine

Usage: In order to keep the product shape and precision, adopts welded sheet structure, motor reducer drive, chain transmission,roller was coated with hard chrome which can keep the molding plate surface smooth and not easy to be marked when it is being stamped.

Length of the main part | About 9000*1650*1500 mm |

Weight of main part | 7 tons |

Voltage | 380 v 50 hz 3 phase |

Roller fixer | Middle plate 20mm thickness |

Frame | 400 H-beam steel welded |

Drive mode | Chain |

Material of rollers | 45# steel, surface hard chromium plating. |

Material of shafts | 45# steel |

Diameter of shafts | φ 80 mm |

Number of rollers | 13 rollers (C8) 17 rollers (C21) |

Main power | 7.5 kw |

Material thickness | 0.3-0.8mm |

Forming speed | 8-20 m per minute |

PLC Control system

Adopted PLC , transducer, touch panel to ensure high speed with stability, precision and lifetime.

Voltage: 380 v 50 hz 3 phase

Language: Chinese and English

Automatic length measurement

Automatic quantity measurement

Length Tolerance: 3 m±1.5 mm

Length inaccuracy can be amended easily.

Unit of length: millimeter (switched on the control panel)

Computer operating panel: touching screen and button together.

Hydraulic Cutting System

Tips: the machine picture only for reference, the actual machine will customize as your requriement.

Feature : Ensure stability, precision and cutting speed

It adopts the hydraulic drive and automatic location to decide the dimension and cut the target products.

Function: Automatic cutting controlled by PLC

Material of blades: Cr 12 quenched

Power supply: Hydraulic power

Components: It contains one set of blade, one hydraulic tank, and one cutter machine.

It is controlled by gear wheel oil pump. After filling the hydraulic oil into the hydraulic oil tank ,the pump drive the cutter machine to begin the cutting job.

Hydraulic motor power: 5.5 kw

Hydraulic oil: 46# hydraulic oil

Components: The system includes a set of hydraulic tank , a set of hydraulic oil pump, two hydraulic pipes. and two sets of electromagnetism valves.

Receiving Table

It adopts welded steel and supported roller to transmit the products.

Table length: 3 m per set

Table quantity: 2 sets