Double layer metal roofing sheet roll forming machine

Double layer metal roofing sheet roll forming machine is the machine that can make two different roof sheets. To meet the requirements for roll forming two different profiles in a limited plant area, the double layer machine is designed. This machine is considered to be one of the most cost-effective roll forming equipment and has been widely used in many industrial plants and steel structures. At present, this kind of machine has been widely used in the United States, Canada, India, Russia, Australia, Asia, Europe, the Middle East and other countries and regions. It can be seen that the double roll forming apparatus has broad market prospects. Compared with the ordinary double layer forming machine, this machine has great advantages. In order to produce different metal roofing sheets and metal wall panels, the machine is equipped with two layers of forming rollers. The palletizing system is adjustable up and down to accommodate the height of the two floors.

Product Description

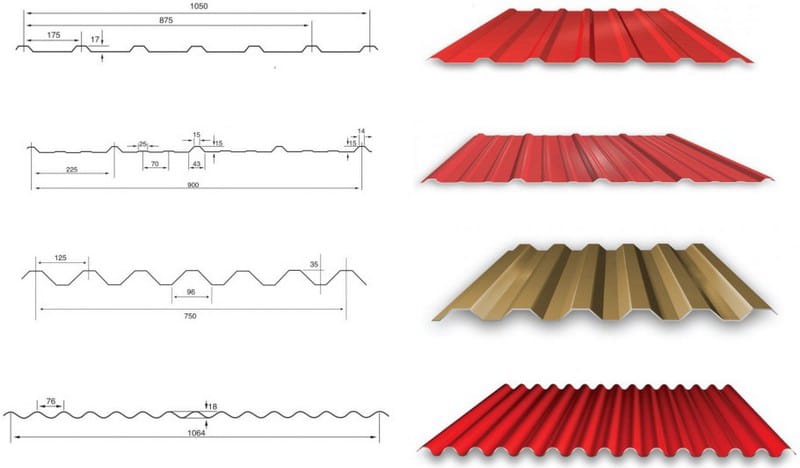

The double layer roll forming machine can be used to produce corrugated steel sheets of two different shapes, such as two wall panels or roof panels, a deck panel, corrugated sheet, and so on. This machine can save a lot of work space and improve work efficiency.

Here are some popular product drawings and pictures for your reference:

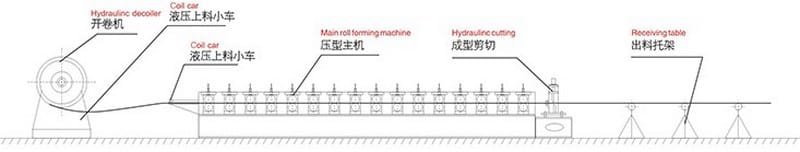

Work flow: Uncoiling→ Feeding material into machine →Roll forming → Auto shearing →Products receiving table

Main parameters :

1 | Machine name | Double layer metal roofing sheet roll forming machine |

2 | Dimension | 8500*1500*1500mm |

3 | Weight | 8T |

4 | Total power | 11KW |

6 | Voltage | 380V/50HZ/3PH |

7 | Material | PPGL,PPGIGI,GL |

8 | Forming speed | 15m/min |

9 | Material thickness | 0.3-0.8mm |

10 | Tolerance | ±1mm |

Main pictures:

IBR/Corrugated tile/panel can be used in many scenes, here are some buildings that built with it ,which is really beautiful

Main parts of our machines:

Packaging & Shipping