Double-Layer Roofing Sheet Two In One Roll Forming Machine For Metal Material

Double-Layer Roofing sheet Two in one roll forming machine refers to normal roofing sheet roll forming machine,have the advantage of can produce two types profile drawings roofing sheet on one machine.and One machine it has one PLC, one motor and one whole body and frame,By this way, the machine takes small space and save cost than buy two normal one-layer type roofing sheet,if you want to produce two types roofing sheet.

(The double-layer roofing sheet two in one roll forming machine for your reference),A metal roof is a roofing system made from metal pieces or tiles. It is a component of the building envelope. One of the main disadvantages of a metal roof is the noise created when it rains outside.Metal roofs can last up to 100 years, with installers providing 50 year warranties. Because of their longevity, most metal roofs are less expensive than asphalt shingles in the long term.For the finished products,usually have the T-type roofing sheet/corrugated roofing sheet/and glazed 3D type roofing sheet.Here some drawing profiles for your reference.

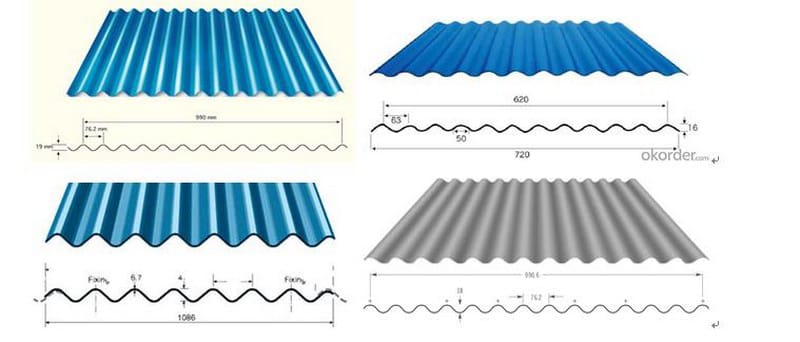

Corrugated type roofing sheet profile drawings for your reference.

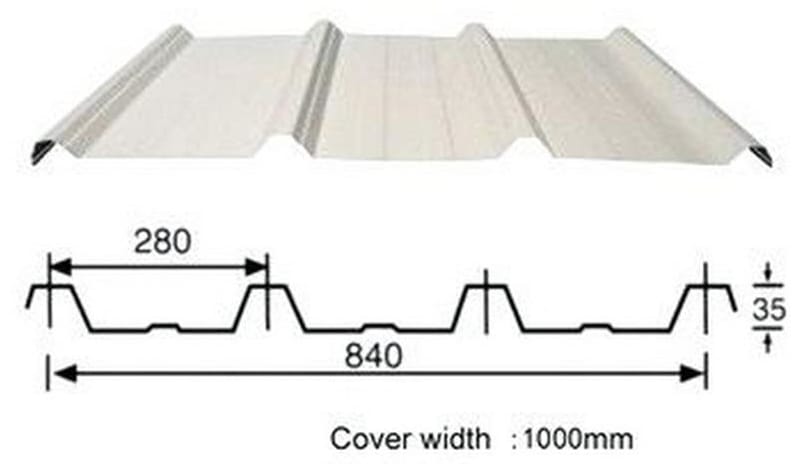

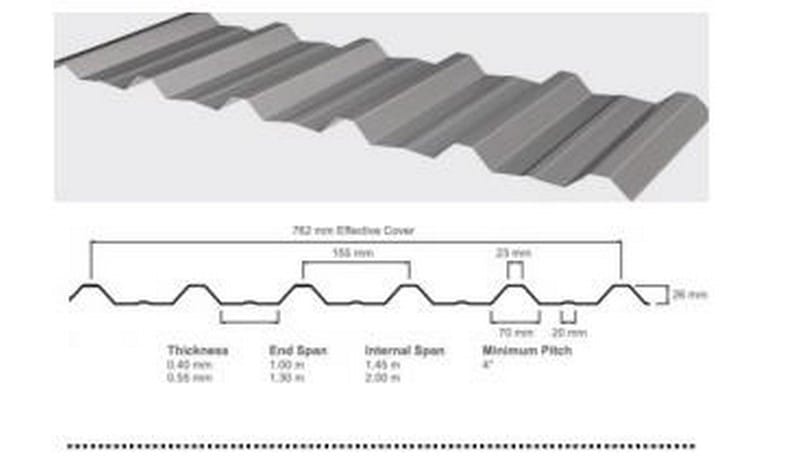

T-type roofing sheet profile drawings for your reference.

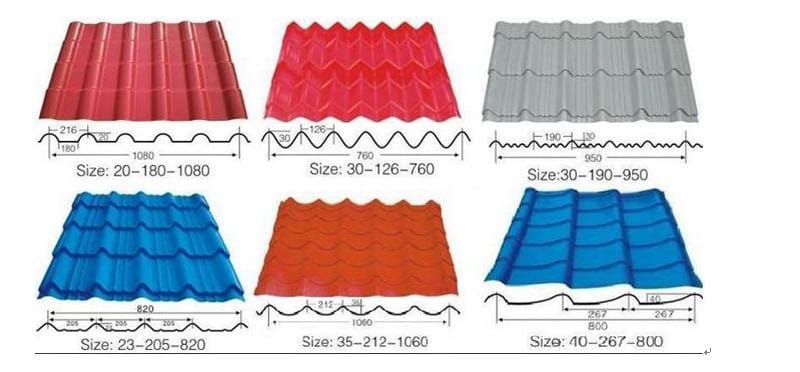

Glazed type(3D effect) roofing sheet profile drawings for your reference.

And as this double-layer roofing sheet two in one roll forming machine can produce two types profile drawings'roofing sheet on one machine,you can choose freely two types profile drawings for produce.(but cannot choose two types glazed type for produce.)

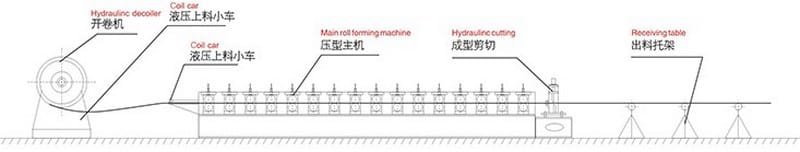

Working Process :

Uncoiling→ Feeding material into machine→ Roll forming→ Measuring length→ Step formed→ Auto cutting→ Products receiving

1. Manual decoiler:

1).Material coil inner diameter: 450mm-550mm

2).Max coil width: customized

3).Carrying capacity: 5000kg

2. Main roll forming machine:

Number of forming steps | R1000: 15 steps, C1000: 15 steps |

Material of shaft | 45# steel ; Outer diameter80mm |

material of roller | 45# steel |

Main motor power | 5.5kw |

Speed of forming | 10-20m/min |

3. Cutting system

1).Hydraulic cutter

2).Blade and mold material: Cr12 steel with quenched treated 60-62℃

3).Cutting system: advanced hydraulic drive, automatic cutting after forming,no distorting or wasting,high level safety factor.(main motor stop cutting)

4. Control system

1).PLC brand:Taiwan Delta/buttons:Franch Schneider.

2).Full automatic produce the finished products,you just need set data of orders.

Double-Layer Roofing Sheet Two In One Roll Forming Machine For Metal Material