YX32-250-1000 Trapezoidal metal roof sheeting roll forming machine for Jordan

Trapezoidal sheets are economic, light, durable, resistant to mechanical failiure and non-corrosive. They are a very popular solution in the case of detached houses, production halls, warehouses and business venues. Trapezoidal sheets are best suited to cover large, flat roofs.Trapezoidal sheets are exceptionally light and as such can be used on roofs which aren’t able to withstand the burden of ceramic tiles. In spite of their low weight, trapezoidal sheets are very durable. The degradative effect of wind and atmospheric effects prove unable to damage them. Trapezoidal sheets are also resistant to water and moisture due to which they never rust. Proper installation of trapezoidal sheets ensures their functioning for many years.YX32-250-1000 is a popular profile roof sheeting in Jordan market. Zhongtuo roll forming machine is designed to produce trapezoidal metal roof sheeting with different specification in batch automatically.

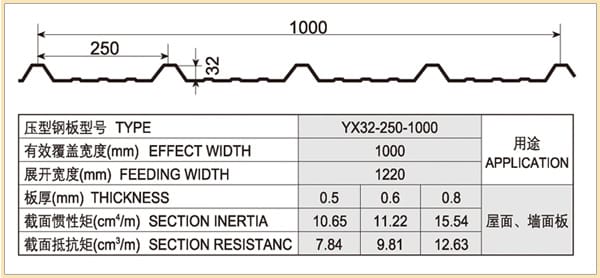

1.Profile drawing as below,and we also can design as customer's request

2.Raw material:0.3-0.8mm,GI,GL,PPGI,PPGL

The specifications of the whole line:

3.Components:

Item | Name | Quantity |

1 | Manual uncoiler | 1 set |

2 | Main roll former | 1 set |

3 | Control cabinet | 1 set |

4 | Hydraulic station | 1 set |

5 | Product table | 2 sets |

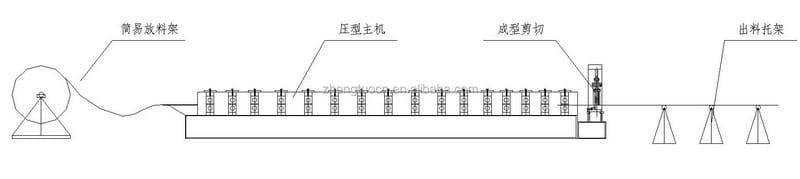

4.Process flow of Trapezoidal metal roof sheeting roll forming machine

5.Manual decoiler(also can use hydraulic decoiler as customers' request)

Capacity:5T

Coil diameter:450-550mm

Coil outer diameter:1500mm

Coil width:1220mm(as customers' request)

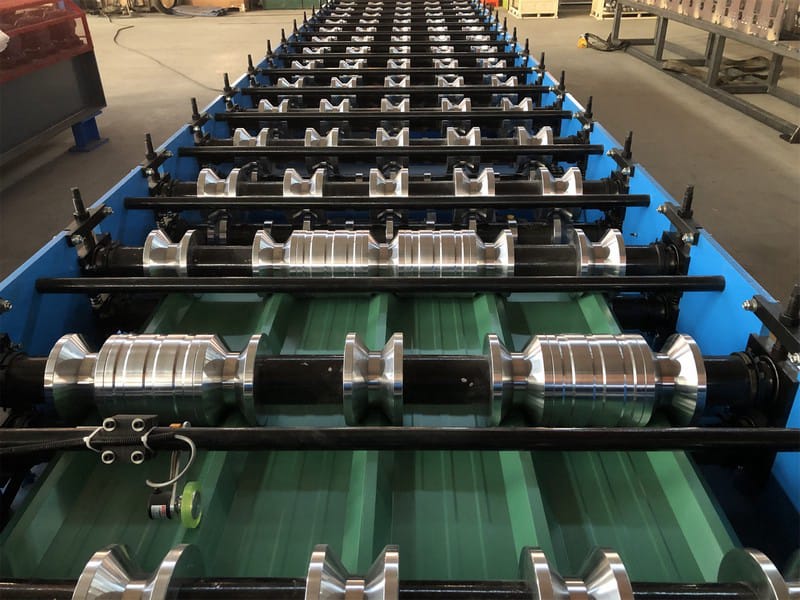

6.Main roll forming machine

Feeding device:with two hand wheels to adjust the feeding of the material,with bearing inside of the feeding rollers.

Frame:400H steel,with 20mm middle plate support

Roller stations:16 stations

Roller materila:45# steel with quenched treatment and hard chroming

Shaft diameter:75mm,solid

Shaft material:45# steel with tempering treatment

Motor power:5.5kw

Speed:0-20m/min

Transmission:By double chains

Voltage:380V,50HZ,3P

7.Hydraulic cutting system

Blade material:Cr12,with quenched treatment

Hydraulic power:4.5kw

Cutting tolerance:±1mm

With fan cooling on the oil pump

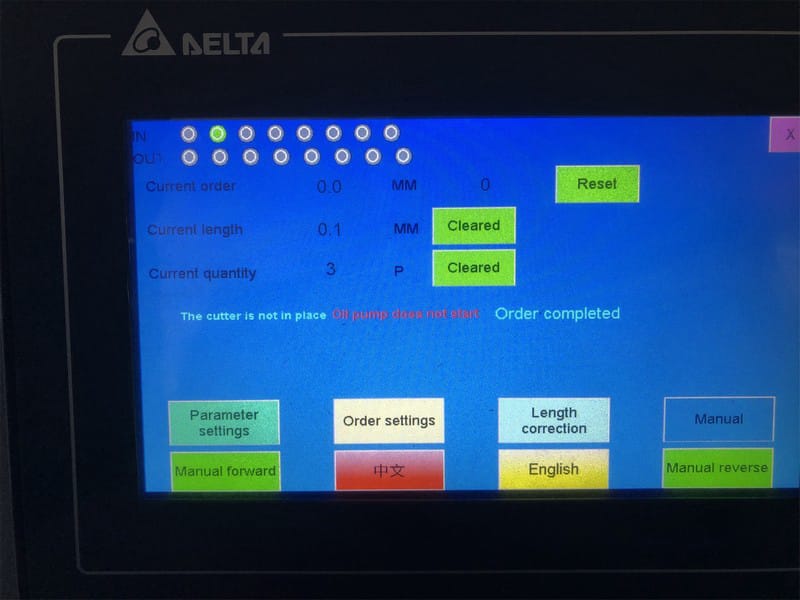

8.Control system PLC

PLC brand:Delta from Taiwan

Frequency converter brand:Delta from Taiwan

Encoder:Omron

Function:Automatic control the length and quantity

Trapezoidal metal roof sheeting roll forming machine for Jordan working video for your reference: