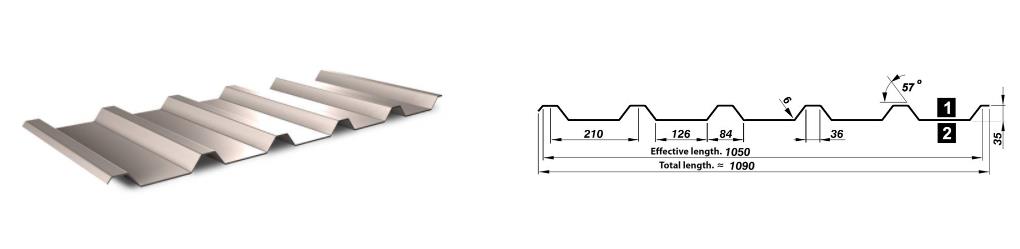

Trapezoidal Roof Sheeting Roll Forming Machine

Roof trapezoidal steel, often used to cover industrial facilities, but also for private homes.It is very much appreciated by architects thanks to its excellent technical characteristics such as durability and good load bearing.Besides panels, available are also the accompanying assurances, load tables, as well as warranties.

Profile Drawing for reference

The machine is composed by the following elements | ||

NO | Item name | Quantity |

1 | 5 Ton manual decoiler | 1 set (you can change hydraulic ) |

2 | Leveling beach with manual cutter | 1 set |

3 | Main forming machine | 1 set |

4 | PLC control system | 1 set |

5 | Hydraulic pump station | 1 set |

6 | Hydraulic shearing | 1 set |

7 | Spare parts | 1 set |

8 | 3m simple stacker | 1 set (you can choose automatic) |

EACH PART DETAIL INTRODUCTION

1. 5 Ton Manual Decoiler

2. Roofing sheets forming machine

1) Leveling beach with manual cutter

Usage: Put the raw material (steel plate) through the beach to manufacture and process, it can guarantee that the products are neat, parallel and everything is uniformity. Please refer to the equipment regulation to know the function of locate board.

Note: 1. Use manual cutter, and in the handrail method to fix input coil.

2. There must be two layers of leveling and designed according to customer requirements.

2) Main Roll Forming System for Roofing sheets forming machine

Usage | In order to keep the product shape and precision, adopts welded sheet structure, motor reducer drive, chain transmission, roller was chromed which can keep the molding plate surface smooth and not easy to be marked when it is being stamped. |

MACHINE | About 10500*1650*1500mm |

Weight of main part | About 11 T |

Voltage | 380V/50HZ, 3Phase |

Roller fixer | Middle plate welded of thickness 20mm |

Frame | 350mm H steel welded |

Frame thickness | 20mm |

Drive mode | Double Chain 1.0 |

Material of rollers | 45# steel surface hard chromium plating. |

Material of shafts | 45# steel |

Diameter of shafts | 90mm |

Number of rollers | 18 rollers |

3) Shearing system

Usage | Automatic cutting controlled by PLC. It adopts the hydraulic drive and automatic location to decide the dimension and cut the target products. In order to increase the speed, we have to change the shearing method. Shearing from down to up or using the servo motor. |

Material of blades | Cr12 quenched |

Power supply | hydraulic power |

Components | It contains one set of blade, one hydraulic tank and one cutter machine, Note: two hydraulic jacks. |

4) Hydraulic Station with cooling fan

Usage | It is controlled by gear pump. After filling the hydraulic oil into the hydraulic oil tank, the pump drives the cutter machine to begin the cutting job. |

Power | 5.5kw for 20L/min Chinese brand. |

Hydraulic oil | 46# |