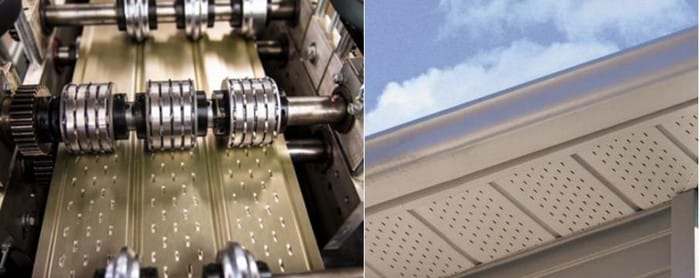

Soffit Panel Rolling Forming Machine

What is the Soffit panel and where to use?

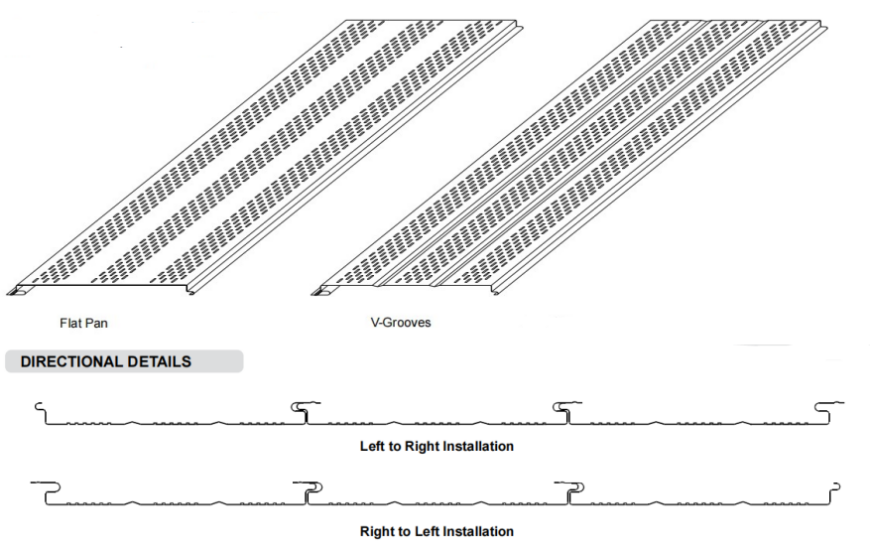

For the Soffit panel, in the market, there are two types one is with punching and one without punching. Here I will take the

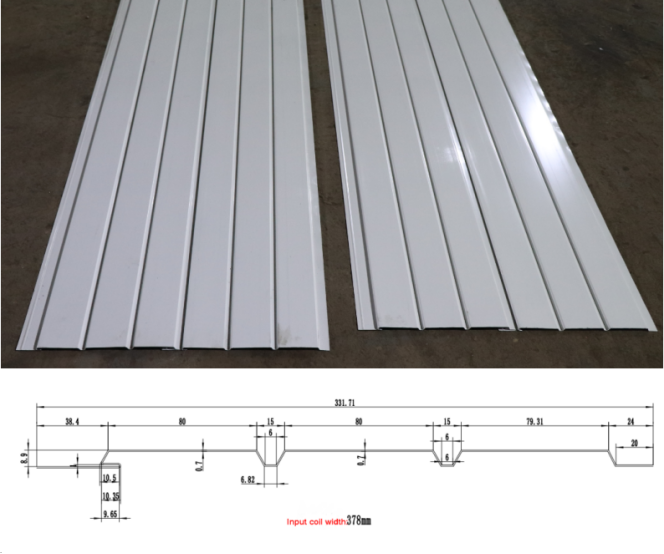

Soffit panel rolling forming machine DESING:

The machine we design using 18 roller stations. The motor and PLC we all use the world famous brand Siemens.

The the punching roller are adjustable according to your needs. Features

Soffit panel rolling forming machine DESING:

Soffit panel rolling forming machine we designed with 18 roller station and to make the punching and without punching adjustable.

The machine we design using 18 roller stations. The motor and PLC we all use the world famous brand Siemens.

The the punching roller are adjustable according to your needs.

Features

Frame Construction: The frame construction we use molding frame or pillar frame to make a rigid frame. The frame is machined to provide a true plane for the assembly of the forming stations. Adjustable feet are provided enabling the machine to be set perfectly level.

Forming Stations: All the forming rolls coming into contact with the painted surface of the conductor pipe are hard chrome plated to insure long roll life and protect the finish. We design the machine using 18 roller station for either can support PPGI , Alum or others.

Driving part: All the stations of the machines are driving stations by gear, top and bottom. They are all spring loaded which creates a constant load on the material. The springs make our gutter machines the most versatile on the market allowing you to run different material with virtually no adjustments. And also the machine can produce the profile with punching or without.

And this Soffit panel rolling forming machine will be equipped with a perforating station. Each panel section will include 5 separate lancing blades on top and mating rings on the bottom. This will create a loop perforation that will be pressed down. The perforation is disabled by raising the upper section. Both the lancing knives and the lower rings can be replaced individually if they should be damaged. They will be made out of A-2 tool steel and then, they will be heat treated and ground for a higher precision. It is something like the rotary punching, you can choose to let it work or not and then the profile will be produced with or without punching.

As to the punching rollers, we design to use the optional control online rotary punching machine. So you can choose to produce it with punching or without.

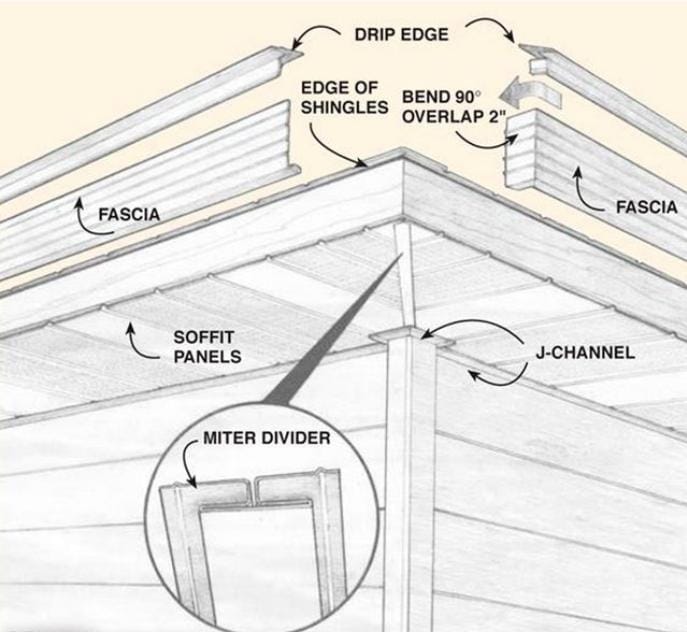

How to install Soffits Panel?

Fix the roof first. If you hide problems, they’ll only get worse! Chances are, if your soffits or roof framing is water damaged, you have serious roof problems that you must solve before starting this project. Even though water won’t damage the new aluminum, you may actually accelerate underlying wood decay by burying evidence of leaks. Common problems are ice dams, shingle edges that are broken off or that don’t project far enough, and even sagging shingles that form a trough just behind the fascia. You may even need a new roof. If you’re not sure, have a pro make the call before you start.

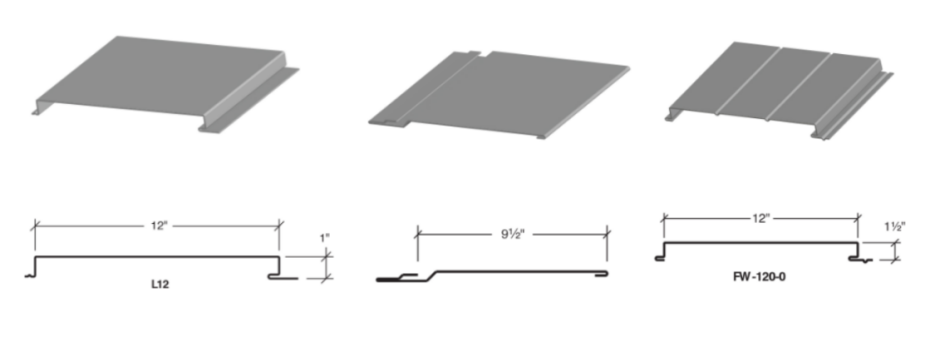

Just figuring out what everything is called is half the battle! Soffit panels are available in 12-ft. lengths, 12- or 16-in. widths and vented or unvented. Vented soffit has thousands of perforations that allow air to flow through but keep insects out. Solid (unvented) soffit has no perforations. Most installers use only vented material, even in areas that don’t need venting, such as gable ends (the peaks at the ends of roofs). Make your life easy—stick with 16-in. wide ventilated panels to simplify ordering and to cover large areas faster.

To calculate quantity, multiply width by length (in feet) of each soffit surface, add them all up to get total square footage and divide by 16 (the square footage of one 16-in. panel). Add 5 percent extra for waste and overlaps.

Fascia:

Aluminum fascia goes directly over the wood fascia and has a lip at the bottom that laps over the outer edge of the installed aluminum soffit. It comes in two standard widths: 6 and 8 in. Measure the width of your wood fascia to determine which width to buy. Measure the entire length of the existing fascia in linear feet, and divide by 12 to establish the quantity of 12-ft. fascia and J-channel sections needed. Then add 5 percent.

J-channel:

J-channel is a (surprise!) J-shaped length of aluminum that the soffit fits into against the house. Use it to anchor any edges of soffit not covered by aluminum fascia.

Drip edge:

Metal drip edge may already be on your home. It projects from under the shingles and directs water away from the surface of the fascia. You can reuse existing drip edge if it’s in good shape and you’re happy with the color.

To calculate the number of pieces of drip edge, divide the total linear footage of the outer perimeter of the roof edge by 10. Then add 5 percent.

Easy does it. Don’t bother climbing around on ladders to measure your soffits and fascia (you’ll get enough of that later). Measure the walls and “guesstimate” overhang lengths to get an approximate total. On gable ends, hold a tape measure at the approximate roof angle, at the halfway point of the wall (directly under the peak), to get lengths for gable trim.