Corrugated Roofing sheet rool forming machine is a type of tile machine, and its remarkable feature is the adoption of a single-side single-guide post shearing method. This guide post structural design provides multiple advantages for the equipment operation: in terms of precision, the guide post enables the shearing tool to maintain extremely high trajectory accuracy during movement, controlling the dimensional error within the millimeter range to ensure that the arc and edge precision of each tile meet the design standards; in terms of service life, the guide post has high surface hardness and wear resistance, and with the lubrication system, it can reduce the wear during long-term operation, and the service cycle of its core components is longer compared to equipment with ordinary structures; although the guide post structure leads to slightly higher initial investment cost of the equipment than conventional tile machines due to high material cost and processing precision requirements, in actual production,Corrugated roof tile making machine can demonstrate efficiency advantages through fast and precise positioning, and the entire process from positioning to completing shearing can be finished within seconds, reducing the debugging time and material waste. Such characteristics of "high precision, long service life and fast positioning" make the single-side single-guide post shearing structure the preferred solution for arc roof tile equipment in complex tile processing scenarios.

Corrugated roof sheet rool forming machine adopts servo tracking cutting technology, and its cutting speed is particularly remarkable. During the cutting operation, the main forming machine keeps running without stopping, and the cutter accurately follows the movement track of the steel plate for synchronous cutting. This dynamic tracking working mode greatly improves production efficiency. The equipment has an extremely fast cutting speed, reaching 25 to 40 meters per minute, which can meet the needs of mass production. It is especially suitable for customers with large production demands and pursuit of fast production speed, such as large factories. In the production scenario of large factories, the huge demand for roof tiles requires efficient equipment support. With its fast cutting speed, the equipment can greatly shorten the production cycle, increase production capacity, help factories complete order delivery in a timely manner, and meanwhile, the continuous and stable high-speed production can also reduce the production cost per unit, bringing better economic benefits to enterprises.

Corrugated Roofing sheet rool forming machine adopts a split forming method, which can make the produced finished products more flat and beautiful. Specifically, split forming decomposes the material forming process into multiple independent and collaborative module operations - for example, first pressing the basic arc of the steel plate through the main forming module, then trimming the edges of the tiles through the side trimming module, and finally eliminating fine wrinkles through the surface pressing module. Each forming module can independently adjust the pressure, temperature and forming track. For example, the arc roller of the main forming module adopts a segmented pressure design, which can apply precise pressure to different parts of the tile to avoid wavy bending caused by local stress concentration in traditional integrated forming; The side trimming module is equipped with fine-tuning precision cutting tools, which can trim the edges of tiles synchronously during the forming process to meet the design standards of right angles or arcs, and eliminate defects such as burrs and curled edges; The surface pressing module repeatedly rolls the tile surface through mirror-treated rollers, just like "ironing" to eliminate the original texture of the metal plate and fine traces during forming, so that the tile surface presents a mirror like smooth effect. This split forming process is like "modular customization", with each link specially optimized for flatness and aesthetics. The finally produced tiles not only have uniform arc and small size error, but also have smooth surface and regular edges. Whether they are used for the arc domes of classical buildings or the sloping roofs of modern villas, they can improve the delicacy of the building appearance with uniform paving effect. At the same time, the flat surface can also reduce rainwater accumulation and dust deposition, and prolong the service life of the tiles.

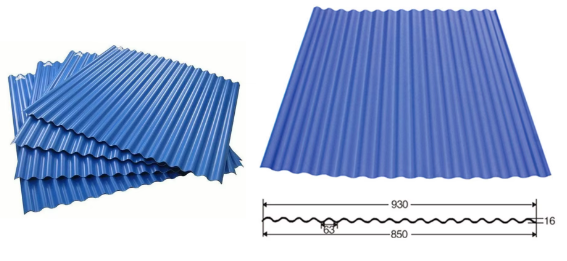

The finished products produced by Corrugated Roofing sheet rool forming machine have clear standard ranges in specifications and dimensions. The wave width of the tiles is roughly maintained at about 63 millimeters. This size design can well adapt to the paving needs of various building roofs. Whether it is a large-area flat-slope roof or a domed structure with an arc, the wave width of 63 millimeters can achieve a tight fit through reasonable arrangement, reducing installation gaps. The thickness of the tiles is controlled between 0.3 millimeters and 0.8 millimeters. Such a thickness range has strong applicability. For example, scenic pavilions, temporarily built roofs, etc., can not only ensure a certain strength but also reduce the overall weight of the roof; the 0.8-millimeter thick specification is suitable for buildings that need to resist strong winds, heavy rains and other bad weather, such as houses in coastal areas, industrial plants, etc. Thicker plates can enhance the wind pressure resistance and deformation resistance of the tiles. Through the precise roll forming system and thickness adjustment device, the equipment can flexibly adjust production parameters according to different material qualities (such as galvanized steel plates, color-coated steel plates, etc.) and usage scenarios to ensure that the wave width and thickness of each tile can meet the design standards, not only meeting the mechanical requirements of the building structure but also conforming to the neat and beautiful requirements of the appearance paving. This standardized specification design also makes the finished tiles have wide versatility in the market, facilitating construction parties to quickly purchase and install according to project needs.