Double-layer roofing sheet machine is a specialized forming device used for the continuous production of double-layer composite color steel tiles. It is widely applied in fields such as building roofs and wall enclosures. Its core function is to composite two layers of color-coated steel plates with the intermediate thermal insulation core material through a series of mechanical processing procedures, forming double-layer color steel tile products with thermal insulation, heat insulation, load-bearing and other properties.

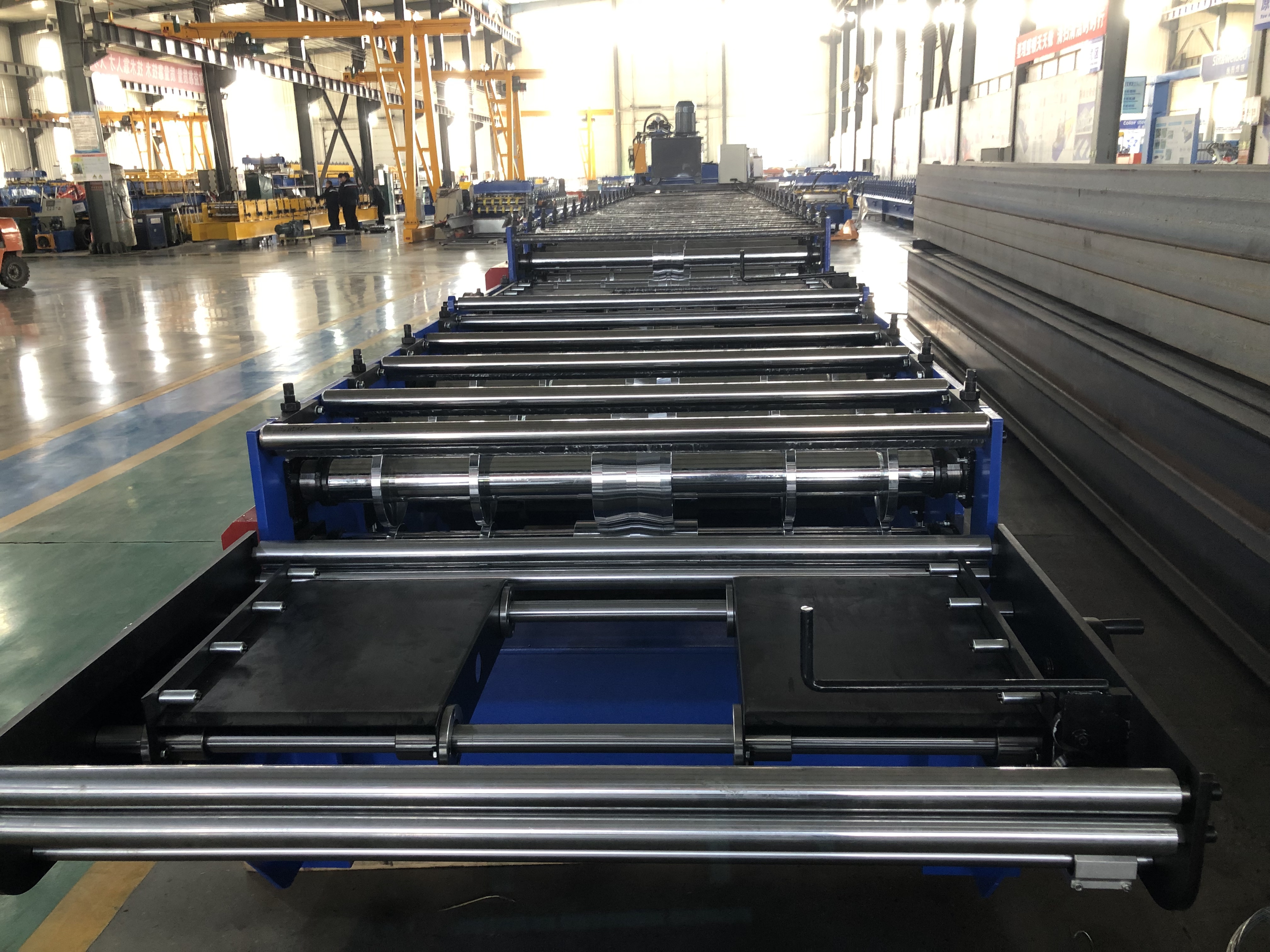

Double layer roofing sheet rool forming machine is an integrated production line, and its core components include an uncoiler, a main forming machine, a shearing device, a hydraulic station, a material receiving rack and an electrical control system. After the steel plate enters from the feed inlet, the main forming unit rolls the pre-formed color steel plate into the final tile profile through multiple groups of continuously arranged rollers, ensuring that the upper and lower tile profiles match. The shearing device is equipped with a high-precision hydraulic shearing machine, which can automatically cut the continuously formed double-layer color steel tiles according to the set length, ensuring flat cuts and precise dimensions. The control system adopts PLC combined with touch screen operation, which can realize functions such as real-time setting of production parameters and achieve automated production.

Double layer roof tile making machine adopts a medium plate structure, and the design of such a structure is an optimized solution aimed at enhancing the operational stability of the equipment. The medium plate structure generally refers to the overall welding or assembly of the equipment's body frame and the supporting parts of the forming mechanism using high-strength steel plates with moderate thickness. By enhancing the rigidity and deformation resistance of the main body of the equipment, it can effectively counteract the vibrations and stresses generated during the production process due to material conveying, roll pressing, or die stamping. This prevents the machine body from shaking or component displacement, thereby ensuring the positioning accuracy of raw materials in the forming process, reducing quality issues such as tile size deviations and surface scratches caused by unstable equipment operation, and enabling the entire machine to maintain stable operation in continuous production.

The reason why double-layer trapezoidal color steel tile equipment can demonstrate stronger competitiveness in the market lies in its all-round upgrade compared to traditional Trapzoidal roofing sheet rool forming machine. A Trapzoidal roofing sheet rool forming machine can replace the work of multiple single-layer equipment. Its compact structural design enables efficient utilization of factory space. Whether it is used to expand the layout of other production lines or reduce the leased area of the factory, it can help enterprises save substantial operating costs.

The equipment can produce double-layer trapezoidal tiles with different wave heights and specifications by flexibly adjusting roll parameters, sheet thickness, etc. It can not only meet the basic roof construction needs of ordinary factories and warehouses but also be suitable for scenarios with higher requirements for thermal insulation and load-bearing, such as agricultural greenhouses and temporary office areas. Customers do not need to look for multiple suppliers for different needs; they can "choose on demand" through products produced by this single type of equipment. This not only simplifies the procurement process but also makes the enterprise's products more competitively differentiated in the market, thereby attracting a more diverse customer group and further expanding the business scope.

Products produced by double-layer color steel tile equipment have a wide range of applications, including roofs and walls of industrial plants, warehouses, and logistics centers; enclosure structures of large public buildings; as well as wall and roof materials for prefabricated houses and integrated houses.