Glazed tile roofing sheet machine

Product Description

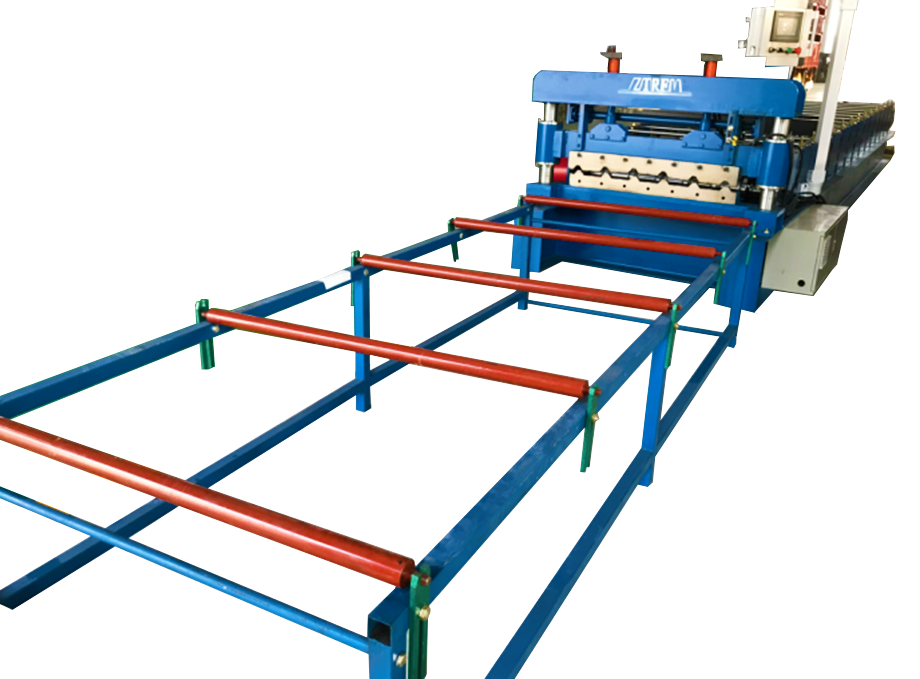

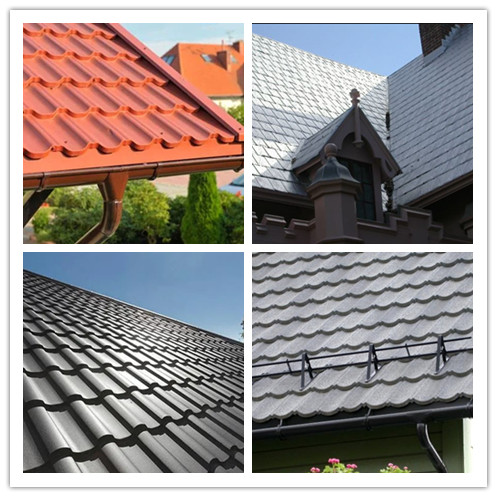

A Glazed tile roofing sheet machine is a device used for mass - producing glazed tile roofing sheets. It processes raw materials like color - coated steel plates, galvanized steel plates, or aluminum plates (usually with a thickness of 0.3 - 0.8mm) into beautiful and durable glazed tile roofing sheets through processes such as uncoiling, guiding and feeding, roll forming, pressing, and length - cutting. These sheets are widely applied in the roofing construction of villas, scenic spots, industrial plants, civil buildings, etc., boasting features like an exquisite appearance and long - lasting durability.

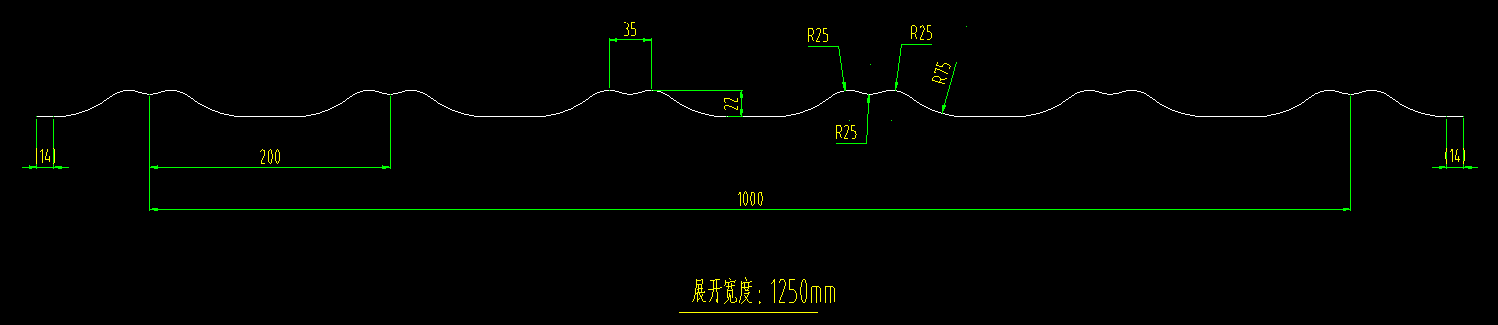

Profile Diagram

Lap Effect

Equipment Requirements and Parameters

Regarding the raw materials:

★ Material: PPGI/GI

★ Material thickness: 0.25 mm - 0.6 mm

★ Material width: 1250 mm

★ Discharge width: 1000 mm

Regarding the manual decoiler:

★ Maximum load-bearing capacity: 5 tons

★ Inner diameter adjustment range: 450 - 550 mm

★ Maximum coil loading width: 1250 mm

★ Others: Equipped with a brake turntable

Forming System:

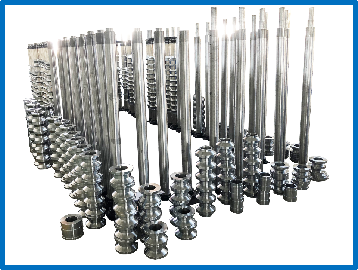

★ Main shaft: 45# steel with quenching and tempering treatment, shaft diameter 80 mm

★ Rollers: 45# steel with chrome plating treatment

★ Inlet: Regular inlet

★ Main machine structure: Medium plate. Base: Welded with 350# H-beam steel and internally equipped with diagonal braces.

★ Forming speed: For glazed tiles, 0 - 4 m/min

★ Main machine power: 5 kW

★ Transmission system:

Double-chain drive

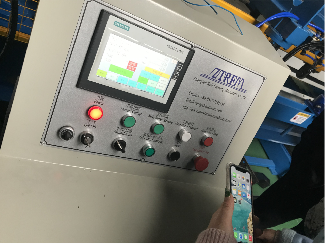

Electrical Control System:

★ Brands of Inverter and PLC: Siemens

★ Display: Touch screen with buttons

★ Display Languages: English, Chinese, Russian

★ Low-voltage electrical appliances: Siemens

★ Encoder: Omron

Cutting System:

★ Hydraulic cutting

★ Drive: Driven by a guide post type oil cylinder

★ Structure: Guide post type

★ Hydraulic power: 4 kW. The pump station is equipped with air cooling.

★ Blade material: Cr12 with quenching treatment

Remarks:

★ Voltage: 380V-50HZ-3P

★ Simple material receiving rack: 1 piece, 3 meters in length and 1.25 meters in width.