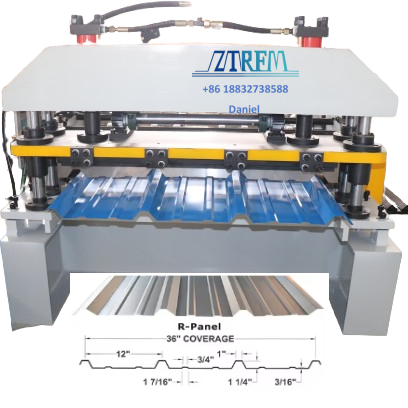

PBR/R/AG Roof sheet roll forming machine

Having precise, long-lasting, and effective PBR/R/AG Roof sheet roll forming machine is crucial to sustaining project progress in the modern construction sector. Trapezoidal roof sheet machine is a vital tool in the industry for producing these panels due to its remarkable performance and broad range of applications.

Typically, PBR/R/AG Roof sheet roll forming machine consists of multiple essential components. With both manual and automated options, the uncoiler offers a reliable coil support for production. Its usual load-bearing capacity is five tons, but other capacities can be customized to satisfy particular client needs.

With its frame, feeder, shaft, rollers, chain drive, motor, cutter, and other components, the roll forming machine is the central component of the apparatus. Stainless steel rollers are used in the feeder to guard against material scratches while in transit. Roof sheet machine rollers are treated with hard chrome plating, which greatly increases their hardness and lifespan, and the shaft is made to be sturdy. Stronger guide columns and tool holders are included with the cutting device, guaranteeing steady cutting machine operation and prolonging the PBR/R/AG roof sheet roll forming machine's lifespan.

Roof sheet machine control system makes use of well-known brands such as Omron encoders, Schneider low-voltage electrical components, and Siemens PLC and touch screen. Zhongtuo factory make it easy for their customers by offering extensive worldwide after-sales support. Even during long workdays or hot weather, the hydraulic system's fan cooling setup efficiently cools the oil and guarantees steady PBR/R/AG roof sheet roll forming machine operation.

Here's how it works: the coil is unwound by the unwinding machine and then fed into the roll forming machine via the feeder. A series of rollers gradually shape the sheet into a trapezoidal form. Finally, the trapezoidal roof panel is produced by cutting it to the specified size using the forming cutting device.

Key Benefits

Swift Production Process

The PBR/R/AG roof sheet roll forming machine utilizes automated production techniques, enabling rapid manufacturing speeds. This significantly boosts production efficiency, catering perfectly to large-scale projects. For instance, some cutting-edge trapezoidal roof sheet machine can churn out 20 meters of panels every minute, drastically cutting down project timelines compared to traditional methods.

Precision in Panel Formation

Thanks to meticulous mold design and advanced manufacturing processes, the roll forming machine guarantees exceptionally accurate molding and consistent dimensions for the trapezoidal roof panels. Whether it's the panel's thickness, trapezoid angle, or overall flatness, everything adheres strictly to standards, ensuring top-notch material quality for construction projects.

Versatile Material Handling

PBR/R/AG roof sheet roll forming machine can process various sheet materials based on customer preferences, including color steel plates and galvanized sheets. It also accommodates different sheet thicknesses and widths, making it adaptable to diverse building scenarios.

User-Friendly Operation

Operating the equipment is straightforward and easy to master. With minimal training, a single operator can proficiently manage the entire production process without needing extensive professional skills. This reduces labor costs and simplifies operational complexities.

Robust and Long-Lasting Design

Constructed from high-quality materials, the equipment features specially treated key components that offer excellent wear and corrosion resistance. PBR/R/AG roof sheet roll forming machine can endure prolonged, high-intensity work, ensuring a long service life and low maintenance expenses.

Machine different section introduction:

Feeding Section

The positioning plate is designed to fine-tune the alignment of incoming materials, making sure they fit the feed width requirements with pinpoint accuracy down to the millimeter. This part helps eliminate any misalignment problems, which means no more jams and a steady flow of materials into the machine.

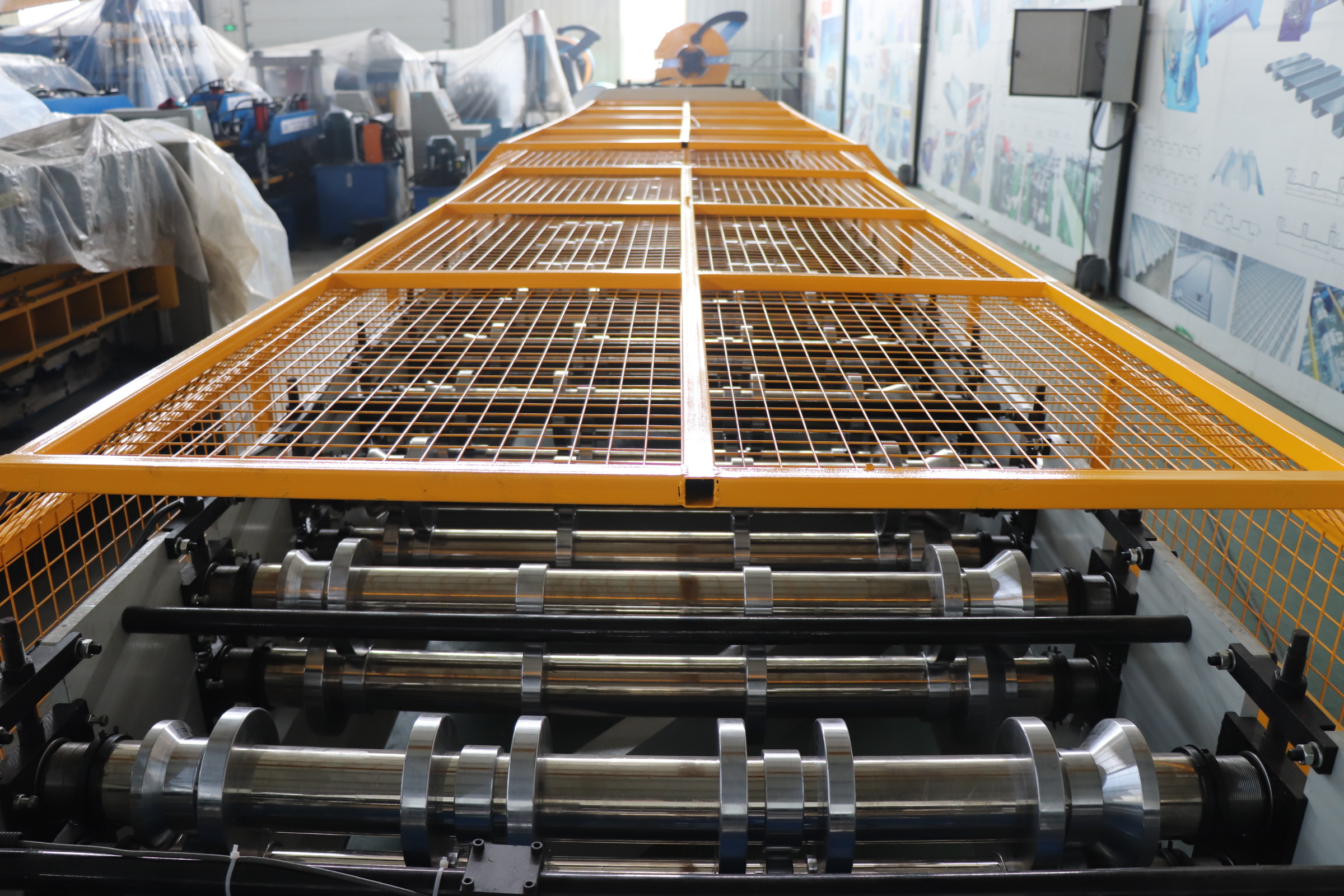

Roof sheet roll forming machine's guide frame provides robust structural support, ensuring everything stays stable even when operating at high speeds. This system includes adjustable guides that can handle different coil widths, allowing for a smooth and controlled transition of material from the uncoiler to the forming section. The guide roller assembly features paired upper and lower hardened steel rollers with polished surfaces, which help minimize friction and promote a more seamless feeding of the material. These rollers are dynamically balanced to reduce vibration, enhancing overall operational stability.

The hand-pull shear is a manually operated cutting tool located just before the material enters the machine. It gives operators the ability to trim any irregular edges or make quick adjustments, ensuring that only properly sized material moves on to the forming stage.

Forming Section

This section comprises a main forming machine equipped with precision-engineered rollers, drive rollers, and forming knives. The rollers are strategically arranged in a multi-station configuration, gradually shaping the material through a series of controlled bends.

PBR/R/AG Roof sheet roll forming machine multi-step forming process ensures exceptional precision, flatness, and consistent profile quality across every production run. Each roller station is calibrated to apply specific pressure, minimizing deformation and maintaining dimensional accuracy even at high speeds.

More details introduction:

Rollers: Made from premium Cr12 mould steel and rigorously heat-treated, these rollers are resistant to wear and deformation, guaranteeing long-term durability and reliable operation.

Cutter Frame: Made of welded joints and 20 mm thick steel plate, this frame offers unparalleled strength and rigidity, able to withstand high-pressure cutting forces without flexing.A robust 4KW hydraulic motor provides precise control over cutting forces for varying material thicknesses by delivering adjustable pressure (0–16 MPa).

Main Motor: Rated at 7.5–15KW with frequency conversion speed regulation, this motor optimizes energy efficiency while allowing seamless adjustments to production speed based on material type and profile complexity.

Maximum Production Speed: Up to 25 meters per minute, ensuring high-volume output without compromising quality.

Material Compatibility: Designed to process GI (galvanized iron), PPGI (pre-painted galvanized iron), and HR (hot-rolled) steel with thicknesses ranging from 0.3mm to 0.8mm and yield strengths between 235–550 Mpa.

High Precision: Cutting tolerance maintained at ≤±1mm, guaranteeing clean, accurate cuts for every profile.

Versatile Application Areas

1. Industrial Factory Construction

Large areas and highly durable roof and wall materials are usually required in industrial factories. Extremely durable, simple to install, and reasonably priced roof panels are produced by the trapezoidal roof panel machine. These panels offer dependable protection, are resistant to extreme weather, and guarantee an effective running of producing processes in factories.

2. Residential Housing

In addition to protecting homes from wind and rain, trapezoidal roof panels' distinctive shape enhances the overall appearance of residential buildings, providing a comfortable living space for occupants.

3. Warehouse Construction

Warehouses have strict demands for roof and wall materials, requiring excellent load-bearing capacity and waterproofing. The trapezoidal roof panel machine generates panels that fully satisfy these requirements, providing reliable protection for goods stored in the warehouse.

4. Commercial Properties

For commercial venues like hotels, clothing stores, and building material stores, the trapezoidal roof panel machine produces panels suitable for roof and wall decoration. Their varied appearances and good performance cater to the dual needs of commercial buildings for both aesthetics and functionality.

5. Temporary Structures and Light Steel Structure Fabrication

Thanks to their quick setup and easy installation, trapezoidal roof panel machines create panels that are perfect for temporary construction projects or building lightweight steel structures. This can really enhance construction efficiency and help cut down on costs significantly.