TR4 roofing sheet making machine

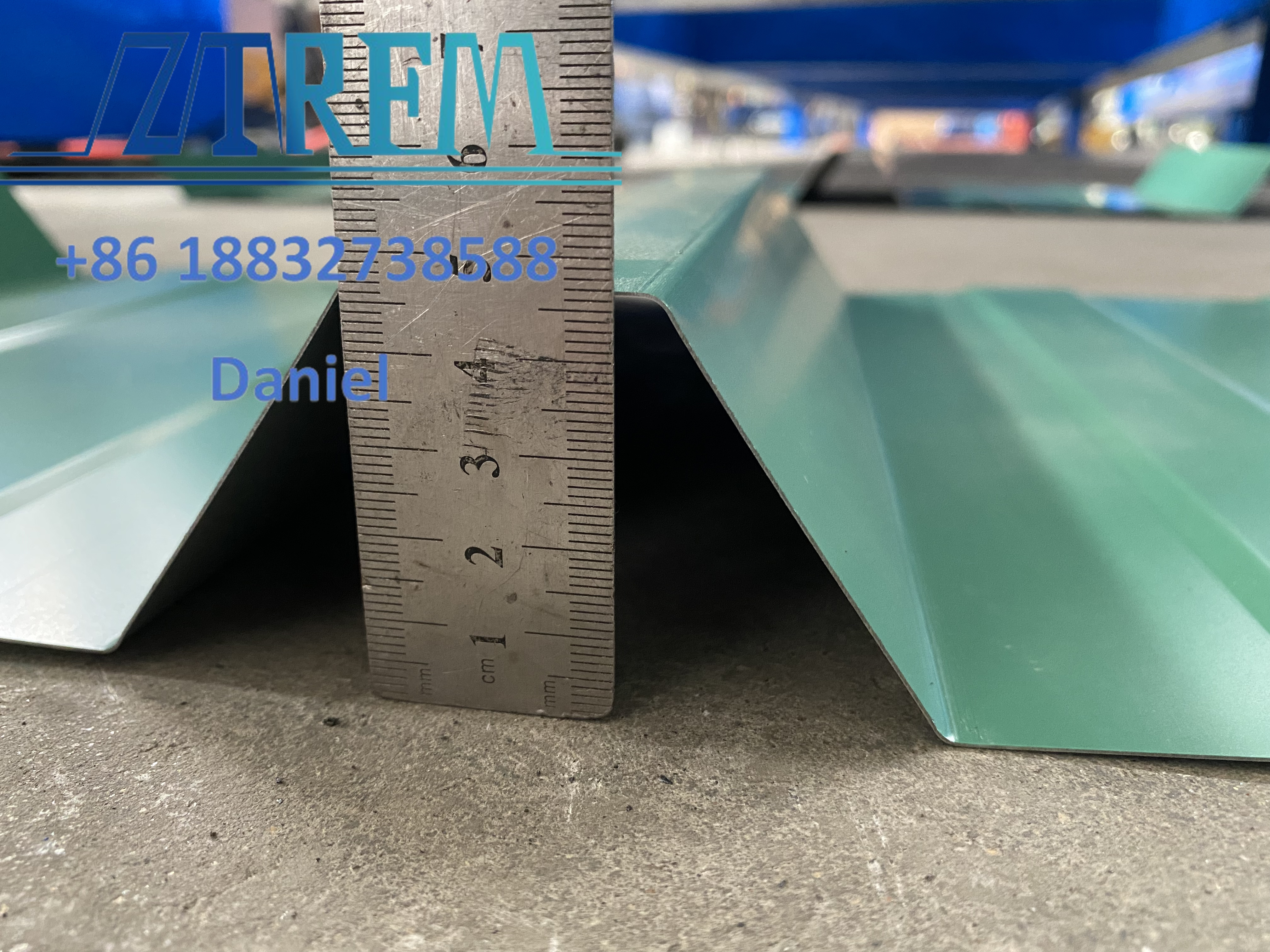

TR4 roof tile machine specially designed to process zinc-aluminum colored steel coils, There are generally 4 waves, the finished sheet height is usually 45mm/48mm, the effective width after forming is 1000mm, in South America, such as Peru, Chile and other countries in the construction market is very widely used!

Our TR4 roof tlie making machine using coil material for the machine: PPGI/GI, in our sales experience over the years the basic material thickness range is 0.3-0.8 mm; the original width of the coil is 1250 mm, the effective width after forming is 1000 mm.

The main shaft of our machine is made of 45# steel with tempering treatment, and the diameter of the shaft reaches 80mm; the rollers are made of 45# steel with chrome-plated treatment to ensure the hardness and precision of the rollers, and the keys and keyways are used to fix and install between the rollers and the shafts to ensure the forming accuracy in the process of using effectively.

Our machine's feeding device is also made of finishing treatment.

1. Equipped with multiple support rollers for smoother feeding.

2. There are two plastic belts in the middle of the platform and two plywood feeders to prevent damage to the surface of the material, which makes the feeding more convenient and quicker.

3. Equipped with a hand wheel, can adjust the feeding size, more convenient.

Straight guide column structure at the feeding port, equipped with front and rear clamping rollers and manual puller to ensure stable feeding and easy adjustment. The board surface is flat and does not damage the paint.

Main roll forming machine | |

Machine frame

| 350mm H beam structure, with 18mm welded steel middle support plate. |

Material of rollers

| High grade 45# forged steel |

Chromed treatment (Chrome thickness:0.05 mm), make the rollers surface more smoothly, improve the hardness and prevent abrasion, anti corrosion increase of service life | |

Forming stations | 22rows |

Diameter of shafts | Φ80mm solid |

Material of shafts | High grade 45#,with heat treatment |

Forming speed | 0-15m/min |

voltage | 380V/50HZ/3P |

Transmission way | By 1 inch chain (double chains) |

Main motor | 7.5 KW |

Cutting blade material | Gcr12 quenched treatment |

Cutting type | hydraulic post cutting |

Driving method | By pillar type Cylinder |

The finished sheet produced by our machines will also be measured professionally:

1. Whether there is any error in the position of the rollers of the bureaucratic machine can be adjusted in time through the measurement data.

2. To understand the edge molding situation through the lap demonstration, to ensure the lap sealing and waterproof.

3. Test the flatness of the sheet to ensure that the finished product has a broader market in the customer's factory, whether it is for their own use or as a commodity for sale.

Trust Zhongtuo, trust Daniel, give you reliable and practical machines and wealth!