The 840 Trapezoid Roof Roll Forming Machine

The 840 trapezoidal steel roofing machine is a roll-forming equipment for making trapezoidal steel roofing sheets. It mainly processes color-coated steel coils, galvanized steel coils, etc. with a thickness of 0.3 - 0.8mm. The machine is driven by a motor and consists of parts like the feeding platform, forming machine, and cutting device. It has 11 - 18 rows of rollers made of 45# steel. The forming speed is 9 - 25m/min and it's controlled by an industrial computer PLC system. It's highly efficient, produces good quality sheets, and has a long service life. It's widely used in the roofing of industrial buildings and other structures.

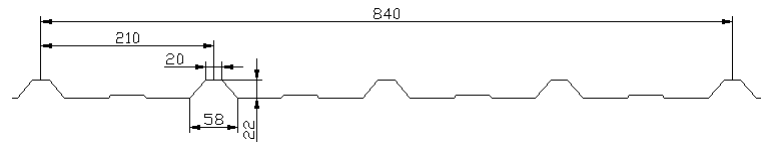

The profile drawing:

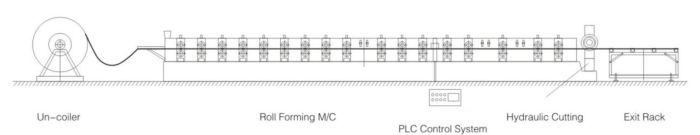

Production process:

Uncoiler-Feeding material into machine→Roll forming→hydraulic cutting→ Products receiving

The following are more details of Trapezoid Roof Roll Forming Machine for your reference:

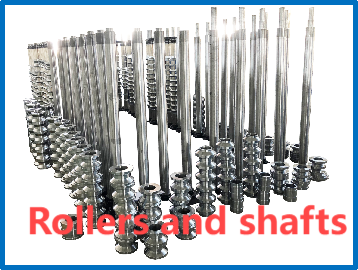

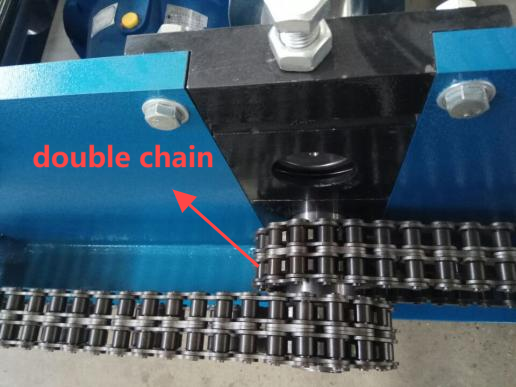

The raw materials for this machine are PPGI and PPGL with a material thickness ranging from 0.4 - 0.6 mm. The machine frame features a 350mm H beam structure along with an 18mm welded steel middle support plate. The rollers are made of high - grade 45# forged steel and have a Chromed treatment. There are 11 rows of roller stations for forming. The shafts, with a diameter of Φ70mm solid, are made of high - grade 45# and have undergone heat treatment. The forming speed can range from 0 - 12m/min. The voltage is 380V/50HZ/3P (as requested). The transmission way is by 1 - inch chain (double chains). The main motor has a power of 5.5 KW. The cutting blade material is Gcr12 with quenched treatment and the cutting type is hydraulic post cutting, with the driving method being by pillar type Cylinder.

Product display

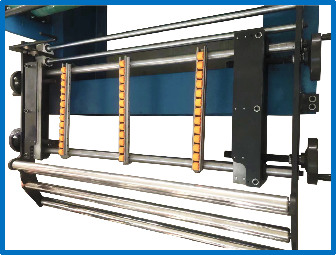

Feeding device

1. Hand wheels on both sides can be used to adjust the feeding width.

2. Four stainless rollers can make the material go into the machine smoothly and prevent the scratch on the material surface.

3. There are three rows of orange plastic rollers can make the steel coil go into the machine smoothly.

Roll forming and transmission device

1. rollers thick chromed good hardness for long service time.

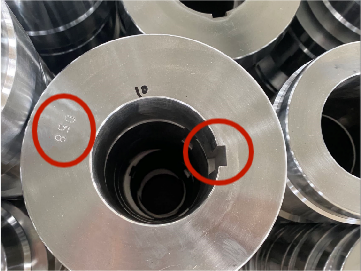

2. Each roller has number and with keynotes, it can fix on the shaft stablely

3.gear and double chain,stable

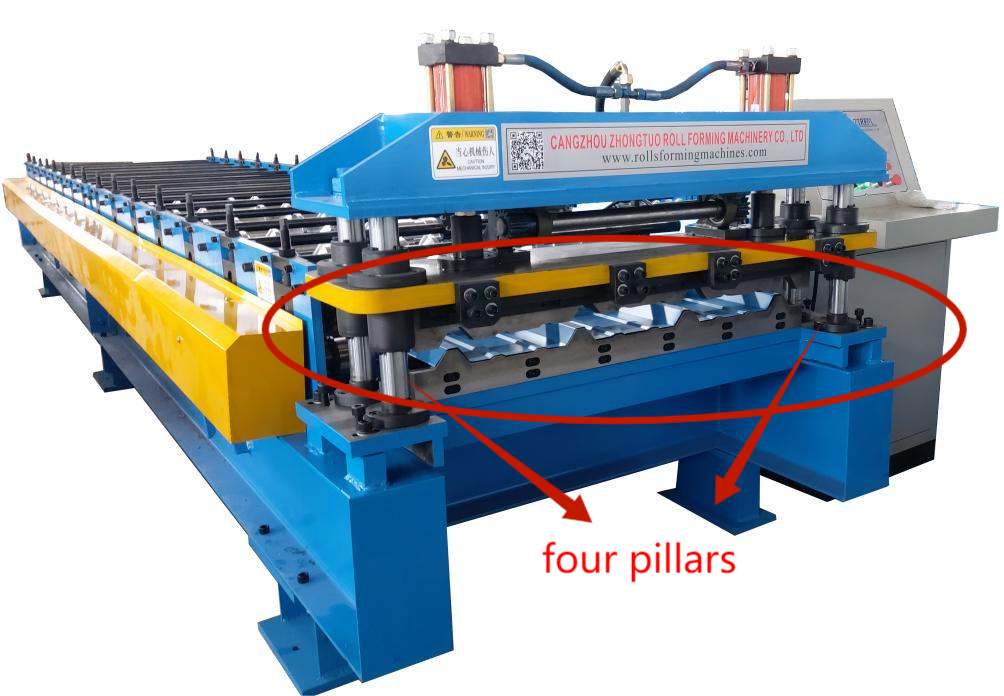

Hydraulic cutting device

We use four pillars cutting system structure, it can make sure the cutting stable.