Cangzhou Zhongtuo's trapezoidal roof tile making machine represents cutting-edge cold roll forming technology, specifically engineered for producing high-precision profiled metal sheets with wave heights ranging from 16mm to 52mm.

I. Core Product Introduction

The system integrates:

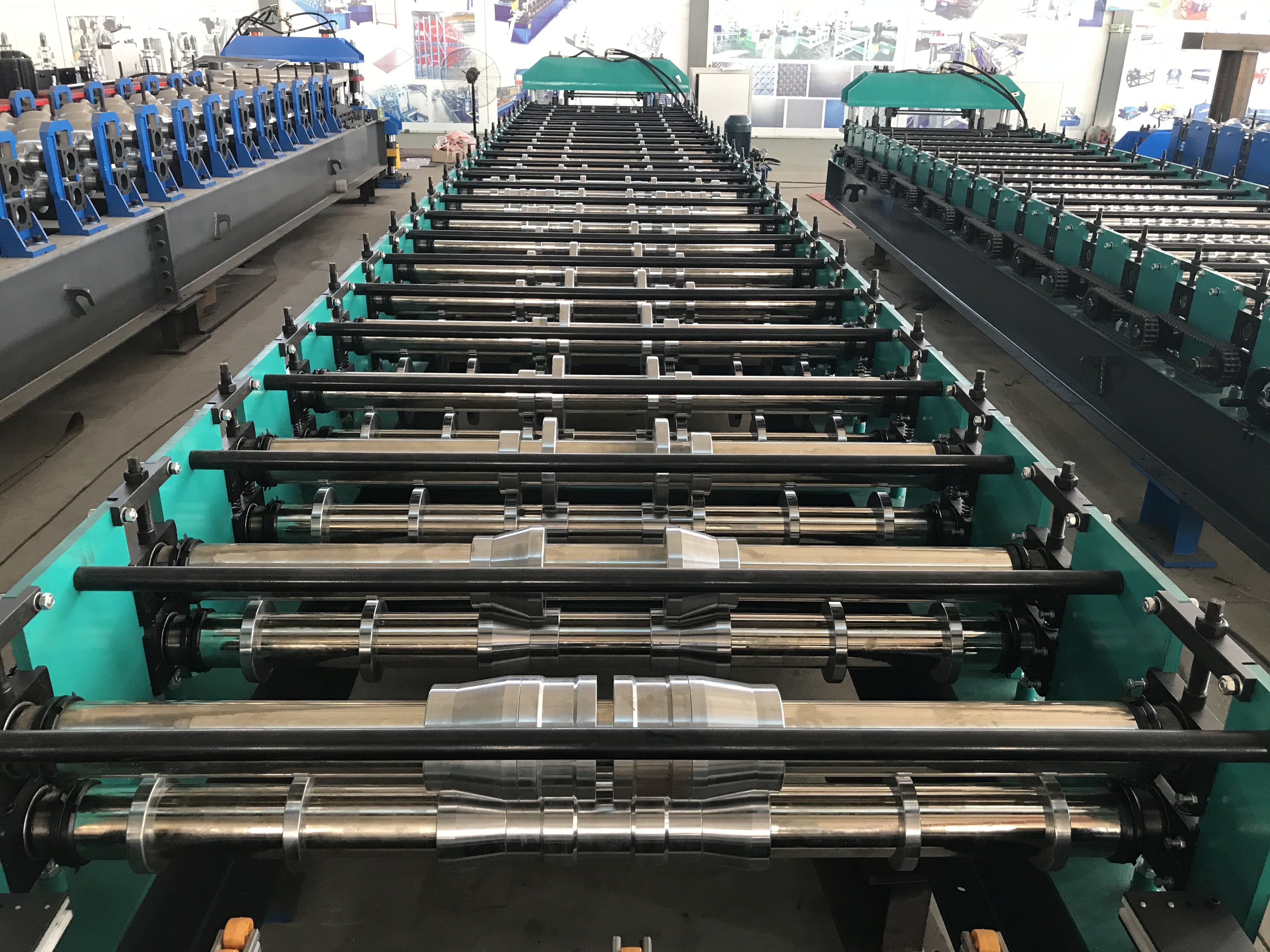

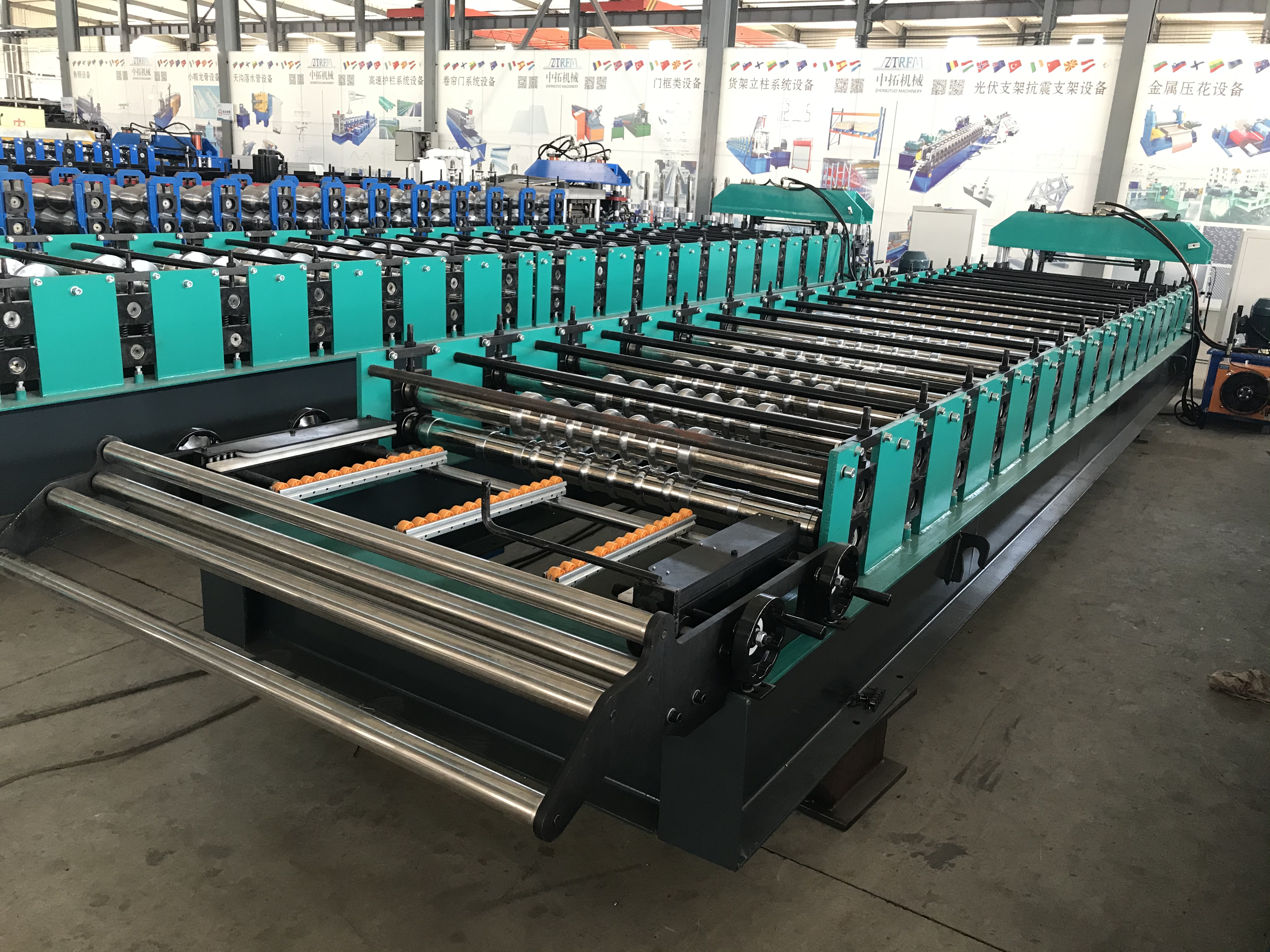

Multi-stage Roll Forming Units

14 precision-grade hardened steel rollers (GCr15 material, HRC 52-58) progressively shape galvanized steel coils (0.3-1.5mm thickness) into uniform trapezoidal profiles with ≤0.8mm/m flatness deviation.Smart Control System

Siemens PLC automates production parameters adjustment, synchronizing servo-driven cutting (±0.5mm length tolerance) with forming speed up to 45m/min.Modular Tooling Design

Hydraulic quick-change molds enable switching between 1040 trapezoidal wave, IBR watertight rib, and Roman decorative patterns within 2 minutes.

II. Key Performance Advantages

1. Unmatched Production Efficiency

70% faster than conventional stamping methods with continuous coil-to-tile processing

98% material utilization via AI nesting algorithms minimizing edge trim waste

24/7 operation capability with IoT-enabled predictive maintenance (MindSphere platform)

2. Superior Product Quality

Dimensional Accuracy: Laser-guided calibration ensures consistent wave pitch

Weather Resistance: Compatible with Galvalume/Zinc-aluminum coatings

Structural Strength: 30% higher load-bearing capacity vs. flat panels

55% lower power consumption through regenerative braking systems

Heat recovery unit recycles 80% of curing oven thermal energy

III. Technical Comparison

Compared to European counterparts

40% cost advantage at equivalent output

Broader material adaptability including APVC-coated steel and copper alloys

More Details find Daniel