The double-sided hydraulic arching roofing sheet machine is a special device used for bending metal plates (like steel plates, aluminum plates, etc.) into curved shapes. With its key technology of double-sided synchronous hydraulic drive, it can efficiently and accurately turn flat plates into workpieces with specific curves or curved surfaces. It is widely used in production fields that need curved structures, such as building decoration, car making, pressure containers, and pipe parts.

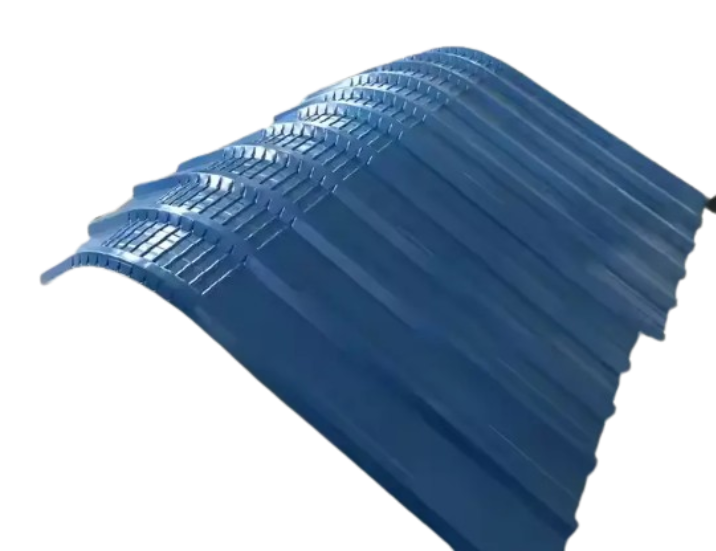

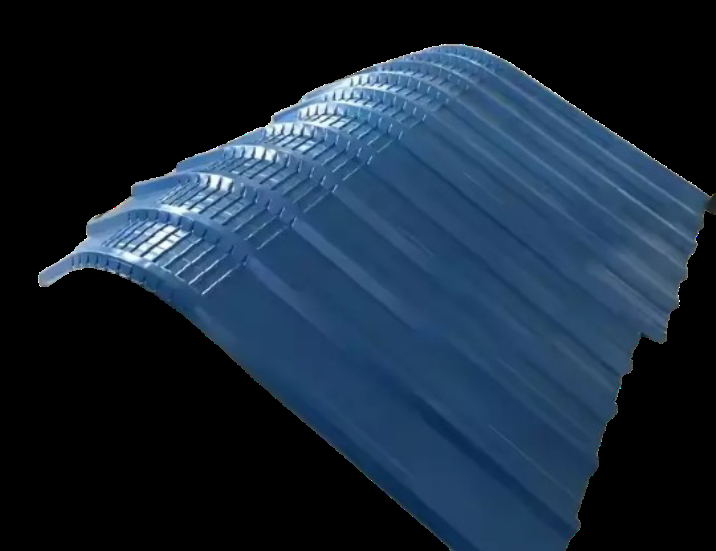

The double-sided hydraulic archingroof tile making machine can work together with tile machines to form a combined process of "tile machine prefabricating basic shapes + arching machine performing secondary curved processing". This provides a flexible solution for the diverse forming of roof tile products. Specifically, tile machines first process metal plates into basic products such as flat tiles and trapezoidal tiles, which already have the basic outline and size needed for roof paving. Then, the double-sided hydraulic arching machine can perform secondary processing on these prefabricated tiles. By applying pressure synchronously through double-sided hydraulic systems, it presses the flat tiles into curved tiles with specific radians.

What's even more important is that the patterns on the arching machine can be customized according to customers' needs. During the arching process, these patterns are pressed onto the tile surface at the same time. This way, they don't damage the tile's structural strength but give the finished product a unique look and feel.This customization ability can not only meet the need to replicate traditional patterns for the renovation of ancient buildings, but also adapt to the design requirements for personalized decoration in modern buildings. It enables the tiles to have both waterproof and load-bearing functions, as well as decorativeness and suitability for different scenarios.

This "tile machine + arching machine" combination breaks the forming limitations of a single device. It not only retains the efficiency of tile machines in mass-producing basic tiles, but also achieves diversification in product shapes and surface details through the secondary processing of the arching machine. In the end, it provides customers with a full-range solution from basic specifications to customized patterns, and is widely used in scenarios such as villa roofs that have high-level requirements for tile shapes.

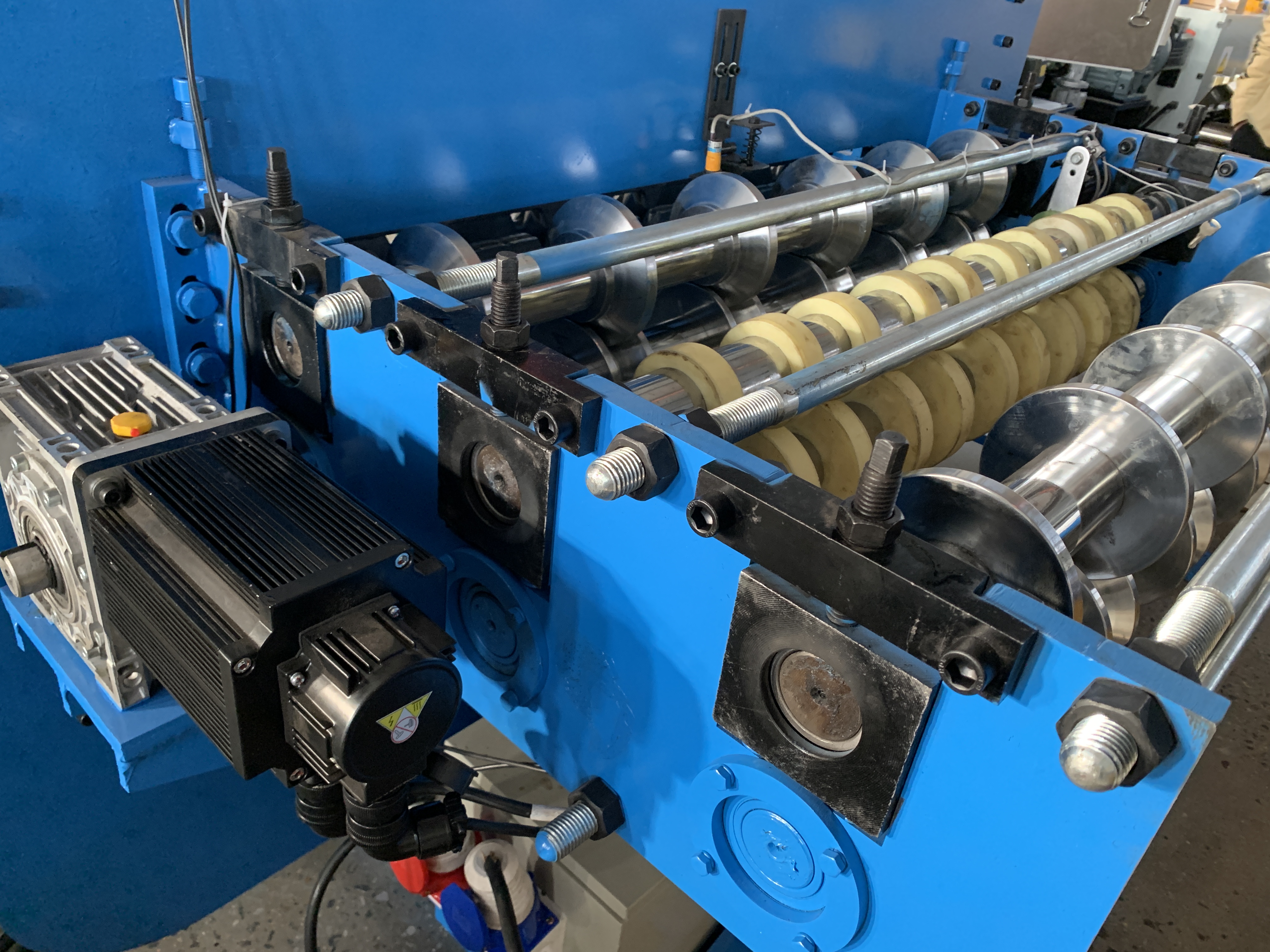

The double-sided hydraulic arching roof sheet rool forming machine uses 45# steel rollers to move the materials, which protects the materials from being scratched. At the same time, the double-sided hydraulic arching machine is equipped with a rocker-arm PLC. It can adjust the speed and angle.And while the machine is running, it can be raised or lowered to prevent the material from being squeezed.

The double-sided hydraulic arching roofing sheet machine has multiple design advantages in material protection and operational flexibility, which are specifically reflected in the cooperative effect of core component selection and intelligent control systems.

In terms of material conveying and protection, the equipment uses 45# steel rollers as transmission components. After quenching and tempering, 45# steel has moderate surface hardness and good wear resistance. At the same time, the surface of the rollers is precision-ground, showing a smooth and flat state. When materials (such as color-coated steel plates, aluminum plates, etc.) are conveyed or rotated on the rollers, the 45# steel rollers can not only provide stable friction to drive the materials forward, but also avoid scratches, indentations and other damages caused by rough surfaces or insufficient hardness. Especially for decorative materials with coatings or platings on the surface, they can maximize the preservation of the appearance integrity and reduce subsequent repair processes.

In terms of operation control and safety protection, the equipment is equipped with a rocker-arm PLC control system. It uses a programmable logic controller to achieve precise control of processing parameters. For speed, it can steplessly adjust the roller rotation speed and hydraulic drive speed according to material thickness and material properties (such as differences in the ductility of metal plates). This ensures that thin materials won't deform due to excessive speed during processing, and thick materials can maintain a stable forming rhythm. For angle, it can accurately adjust the arching angle through preset programs (such as switching between various angles from gentle curves to sharp bends). This meets the curvature requirements of different workpieces, and parameter adjustment is intuitive and convenient without complicated mechanical debugging.

In addition, the machine's built-in lifting adjustment function further ensures processing safety.During machine operation, if the system detects a risk of material squeezing due to positioning errors or uneven thickness, the lifting mechanism will automatically adjust the gap between the upper and lower molds in real-time. By increasing this clearance, it prevents the material from wrinkling or breaking caused by excessive pressure. At the same time, when changing molds or handling abnormal situations, the lifting function can also quickly raise the upper mold, providing safety guarantees for the operating space.

This design, which combines material protection, adjustable parameters and safety protection, enables the double-sided hydraulic arching machine to not only ensure processing accuracy, but also greatly improve its adaptability to materials of different types and specifications. It is especially suitable for production needs where high surface quality of finished products is required and processing scenarios are diverse. What's more, it saves a lot of labor – only one worker is needed to operate it.