High speed C21 C35 trapezoidal roof tile making machine

High speed C21 C35 trapezoidal roof tile making machine description

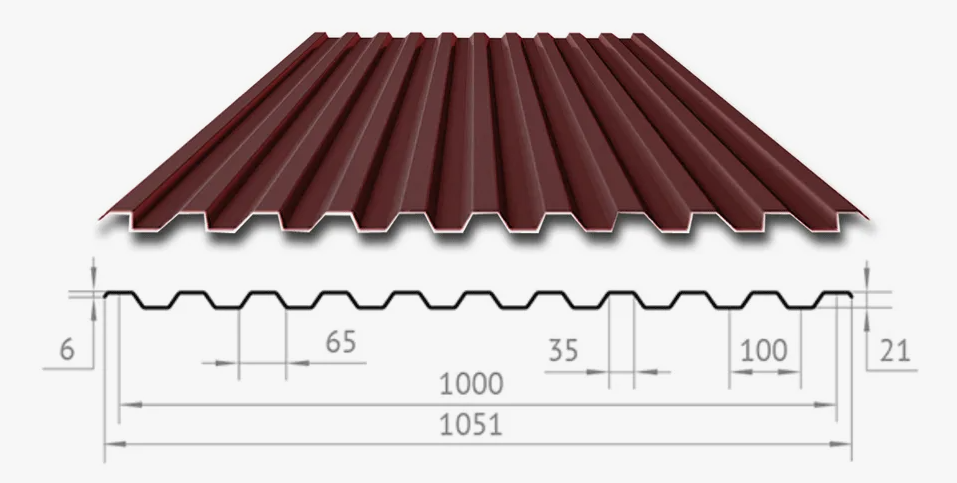

Zhongtuo High speed C21 C35 trapezoidal roof tile making machine each row of rollers equipped with an independent gear box with a transmission ratio of 1:1. The machine production speed can reach 25-40m/min. The machine's version C21 and C35 can be customized. The detailed version diagram is as follows

Design idea:

Fast speed-25-40m/min forming speed ,very fast ,more efficiency.

Stable forming-the roller stand is vertical cast steel stand ,gearbox driving,very strong ,the forming very stable and final product very accurate.

Profile drawing for reference

Roofing sheet has many different shapes,usually different countries have its own popular design ,we can customize the machine as customers’ demand.The C21 and C35 panels are very popular in Russia and Central Asia. We also offer AG Panels and R Panels for the US and Canada, as well as TR4, TR6, and T101 for South America. Our machines are highly customizable, and our dedicated team of engineers will design professional CAD drawings based on your needs and provide expert 3D prototyping demonstrations.

Parameters

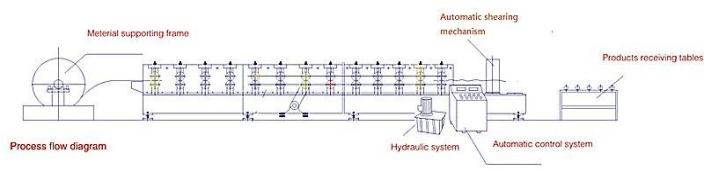

High speed C21 C35 trapezoidal roof tile making machine processing flow

Uncoiling → Feeding material into machine →trapezoidal roll forming machine → Auto cutting →Products receiving table

1. Feed mechanism with support bracket and three rows of stainless steel auxiliary feed rollers.

2. 90mm arch structure, with additional medium and thick plate processing frame and trapezoidal legs.

3. 80mm double-locking belt retaining pads, with active up and down movement of the feed and discharge shafts.

4. 20 rows of rollers + ribbed rollers (45# steel, chromium-treated and chrome-plated; the ribbed rollers are hardened and chrome-plated, and the spacers are chrome-plated).

5. 140# gearbox transmission (one gearbox per row).

6. Dual-cylinder guide column hydraulic shearing with shutdown cut-off.

7. 11KW transmission motor, 5.5KW large valve pump station with air cooling.

Raw material | PPGI,PPGL |

Material thickness:24/26 gauge (0.4-0.6 mm) | |

Machine frame | 350mm H beam structure |

Material of rollers | High grade 45# forged steel,Chromed treatment |

Roller stand | Vertical cast steel structure |

Forming stations | 16 rows |

Diameter of shafts | Φ80mm solid |

Material of shafts | High grade 45#,with heat treatment |

Forming speed | 25 m/min |

voltage | 380V/50HZ/3P (as requested) |

Transmission way | By gearbox |

Main motor | 11 KW |

Cutting blade material | Gcr12 quenched treatment |

Cutting type | Hydraulic post cutting |

Driving method | By pillar type Cylinder |

C21 C35 trapezoidal roof sheet machine product display

Capacity:5 tons

Coil inner diameter:450-550mm

Feeding width: max 1220mm

Function:Supporting the coils and doing uncoiling,It adopts the hydraulic cylinder to make the decoiler expand and fit to the inner diameter of coils. It is equipped with the cantilever.Motor drive the coils running and can do forward and reverse running as well as do the decoiling with tension.

Feeding device

1. Hand wheels on both sides can be used to adjust the feeding width.

2. Four stainless rollers can make the material go into the machine smoothly and prevent the scratch on the material surface.

3. There are three rows of orange plastic rollers can make the steel coil go into the machine smoothly.

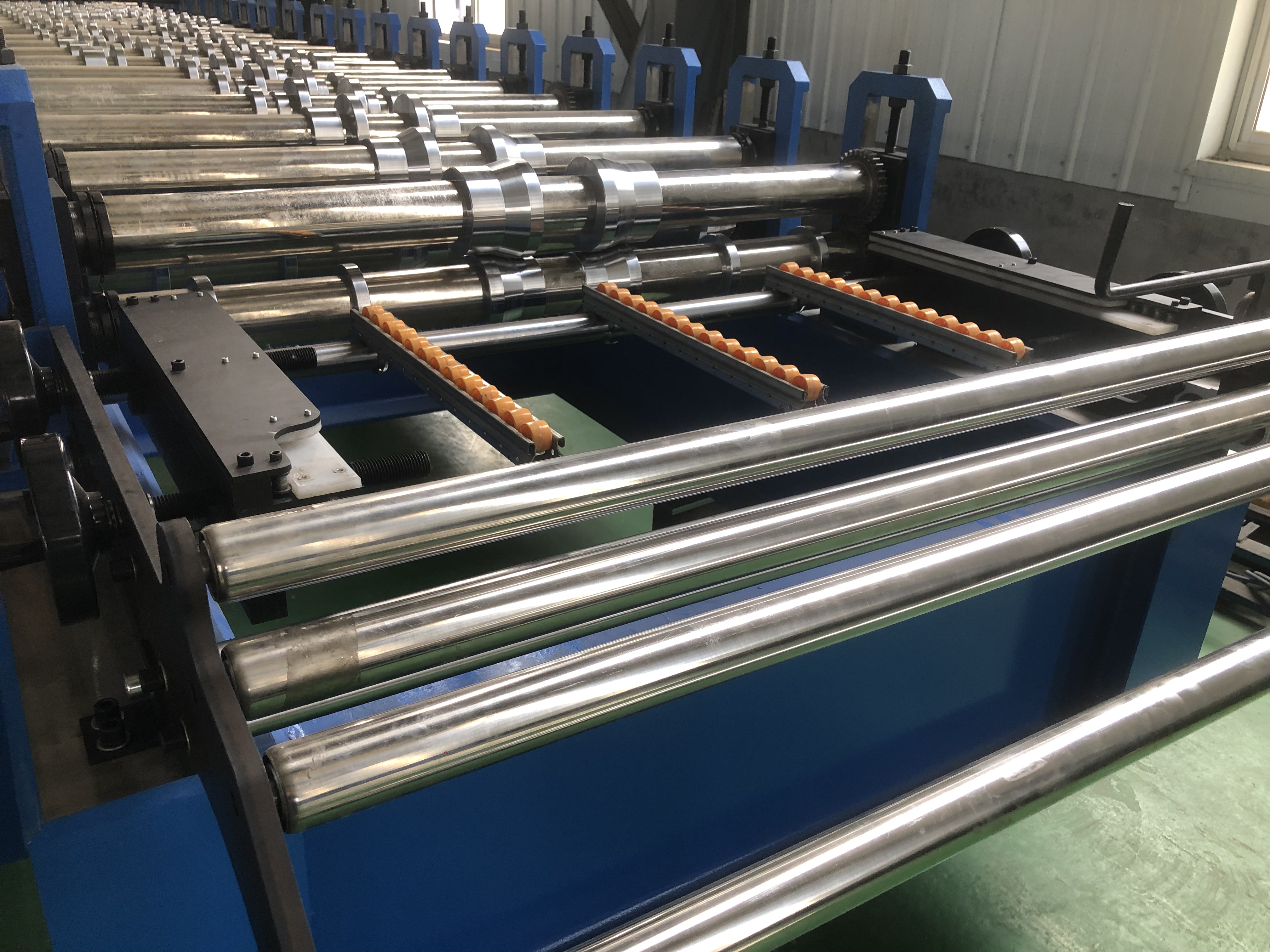

Roll forming and transmission device

1.High speed C21 C35 trapezoidal roof sheet roll forming machine rollers thick chromed good hardness for long service time.

2.Each roller has number and with keynotes, it can fix on the shaft stablely

3.Gear and double chain,will more stable

Hydraulic cutting device

Our high speed C21 C35 trapezoidal roof tile making machine use four pillars cutting system structure, it can make sure the cutting stable

PLC control system

PLC brand:Delta(Taiwan) PLC, and transducer and touched screen

● Encoder brand:Omron

● Electrical components:Schneider

●Operating language:English and Chinese(or as requested)

You can set the orders on this part,changing product length and quantity,it is really easy to operate,and there are aviation plugs to make it much easier to install the machine while it arrived.

Hydraulic station

● Hydraulic station motor:7.5KW

● Hydraulic oil:46# hydraulic oil

● Main components:Include a set of hydraulic tank, a set of hydraulic oil pump, two hydraulic pipes. And one of electromagnetism valve

Automatic palletiser

Function :Collect the finished product automatically ,save labor,and very efficiency.

The length of our palletizer can be customized according to the length of the customer's finished product. Automatic Stacker mainly composed of a longitudinal receiving pallet and a transverse conveying drag chain, which is used in conjunction with the control system of the forming machine. It can realize full-automatic production and receiving and discharging, save labor, and one worker can operate a forming production line.

Why suggest your C21 C35 trapezoidal roof tile making machine add Automatic palletiser?

1.Improve product quality: The automatic palletiser stacks according to the preset procedures to ensure the neatness, compactness and beauty of the product, so as to improve the appearance quality of the product and market competitiveness.

2.Space saving: Automatic palletiser can be stacked according to the rules to maximize the use of the stacking space, improve the utilization rate of warehouse space, and reduce the storage space occupation.

3.Improve safety: The use of automatic palletizing machines reduces the need for personnel to work in dangerous areas and reduces safety risks in the working process.

4.Reduce human error: The programmatic operation of the automatic palletizing machine reduces the possibility of human error and ensures the stability of production.

5.Improve the degree of automation: The application of automatic palletizer is an important part of industrial automation, which helps to improve the automation level of the entire production line.

6.High flexibility: The automatic palletizing machine can adapt to products of different sizes and shapes, and is easy to adjust and adapt to different production needs.