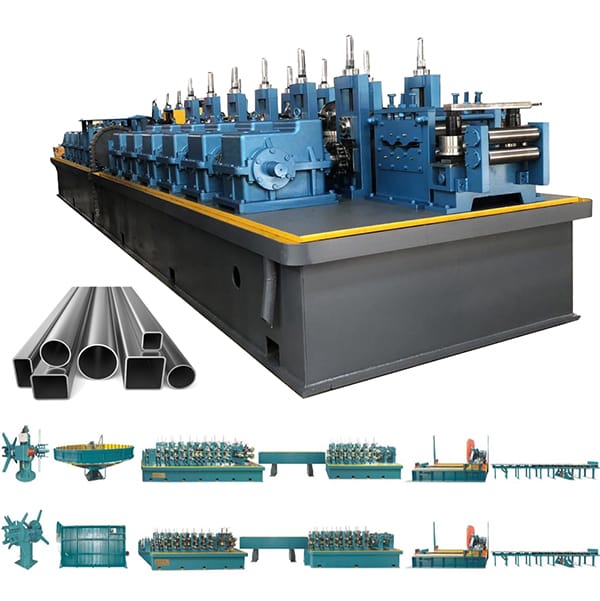

High Frequency Welding Pipe Making Machine Line

NO.4 ROAD, ECONOMIC DEVELOP ZONE, BOTOU CONUTY, CANGZHOU CITY, CHINA

High Frequency Welding Pipe Making Machine Line

With the introduction of advanced technology from American, Japan, taiwan into our company,the high-frequency welding pipe making machine line we specialize in, is well distributed incraftwork, high productivity, easily operated and the equipments are of reliable quelity, and haveachieved automation on a high level.

Products Display

BRIEF INTRODUCTION OF PRODUCTS

1.HIGH-FREQUENCY WELDING PIPE MAKING MACHINE LINE

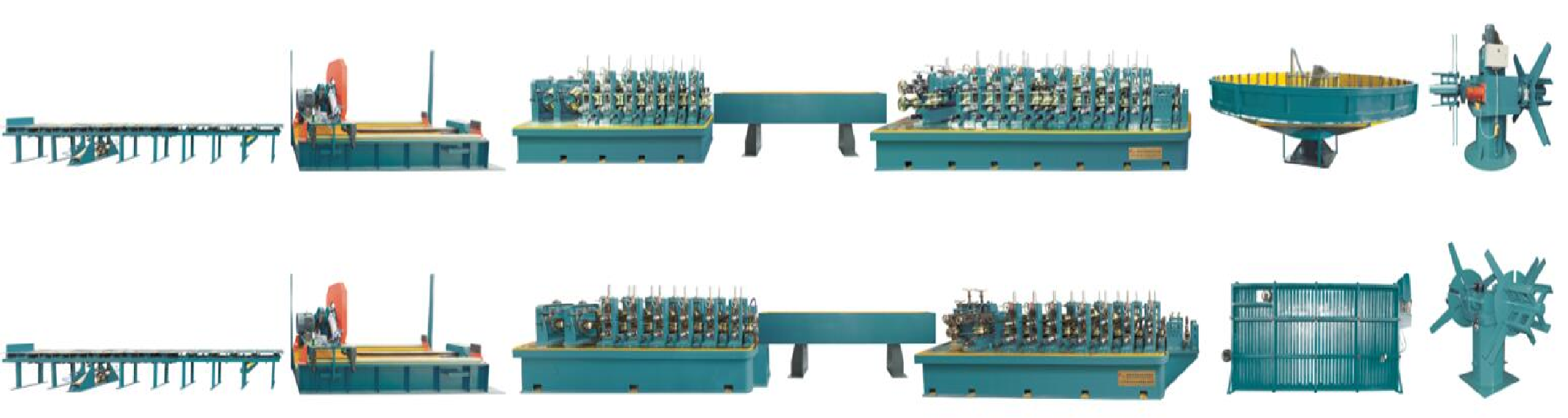

2.STRAIGHT SEAM AND HIGH FREQUENCY WELDED PIPE MILL LINE

3.BG SERIES HIGH-PRECISION STAINL ESS STEEL PIPE MILL LINE

4.PACKAGE CALCIUM TUBE UNIT

5.GW SERIES ROLL-FORMING MILL LINE

6.ELECTRONIC HEATING PIPES, REFRIGERATOR PIPES,AIR CONDITIONER PIPES

7.COLD-CUTTING FLYING SAW

8.WELDED PIPE MOULD-ROLLERS

9.PRODUCTS APPLICATION FILEDS

10.WORKING -FLOW CHART FOR WF SERIES PIPE- -MAKING MACHINE

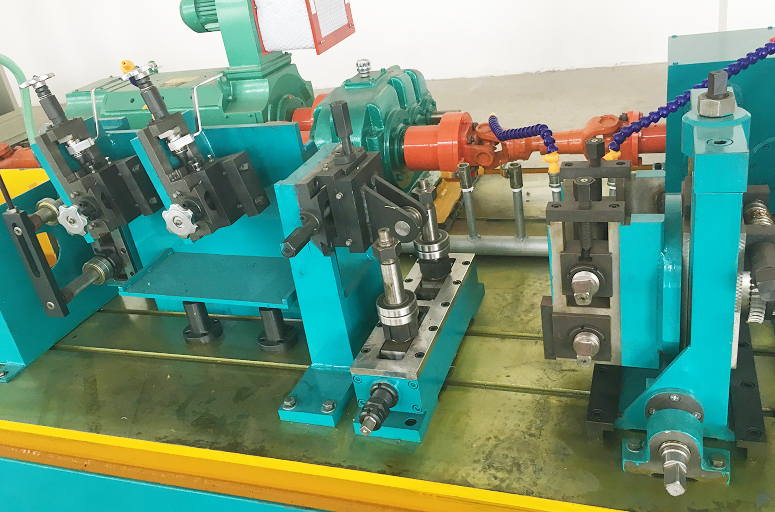

Parts to introduce

Main machine-leveling part

Feeding device: A set of seven-roller passive leveling, a pair of guide rollers

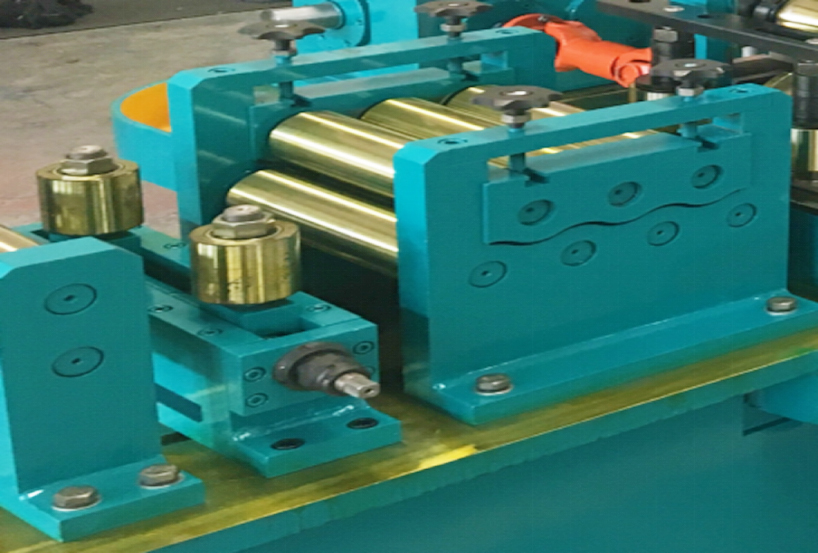

Main machine-rolling parts

Mill entry flattener by five-roll passive levelling, one pair of sending roll, two pairs of vertical roll.

-Gear box & universal joint: 7 sets

- Material of gear box: cast steel

- Material of gear: 20CrMnTi

-Main motor: 55kW

- Material of gear box: cast steel

- Material of gear: 20CrMnTi

-Main motor: 55kW

Sizing part:

Sizing mill gear box, universal joint

Sizing mill consist of:

Driven stand: 5 sets (Horizontal) with diameter Ø60mm, material is 40Cr

Side roll stand: 5 sets(Vertical) with diameter Ø40mm, material is 40Cr

Gear box & universal joint: 5 sets made by cast steel

Sizing mill consist of:

Driven stand: 5 sets (Horizontal) with diameter Ø60mm, material is 40Cr

Side roll stand: 5 sets(Vertical) with diameter Ø40mm, material is 40Cr

Gear box & universal joint: 5 sets made by cast steel

Deburring device With cooling system.

A master valve (ball valve) is connected to the entrance of each main pipeline of the forming unit, cooling water tank, and sizing

unit; each forming and sizing roll is equipped with an adjustable plastic cooling pipe to supply the cooling liquid, and the

cooling liquid flow is cooled by each plastic Control valve control of pipe;

unit; each forming and sizing roll is equipped with an adjustable plastic cooling pipe to supply the cooling liquid, and the

cooling liquid flow is cooled by each plastic Control valve control of pipe;

Electric Control System

2.Single D.C. drive and control for forming and sizing mill.

D.C. drive,

Main D.C. drive panel control (instrument etc.)

Mill operation panel (speed adjustment, control etc).

8.3 Flying cut-off control system

Saw carriage drive by DC motor 15KW,

LCD operation pane

(Length and batch setting control instrument etc).

Product Advantages

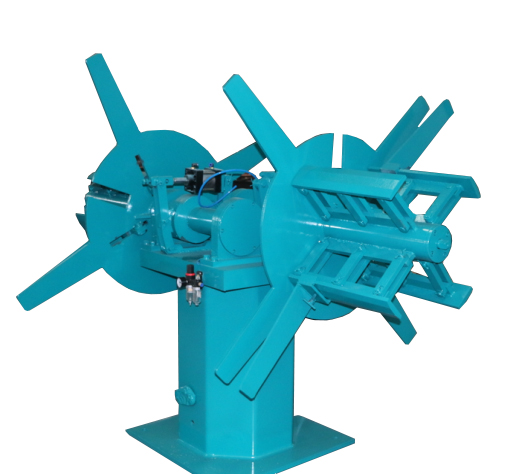

Cage Loop:

Its function is mainly to store a certain amount of steel belt to supply the host before the end of the steel belt is welded, so as to ensure that the continuous production of the host is not stopped during the strapping time.

(1) Structure type: squirrel cage plate weld ment, equipped with automatic feeding and discharging mechanism.

(2) Storage capacity: 150-300M.

(1) Structure type: squirrel cage plate weld ment, equipped with automatic feeding and discharging mechanism.

(2) Storage capacity: 150-300M.