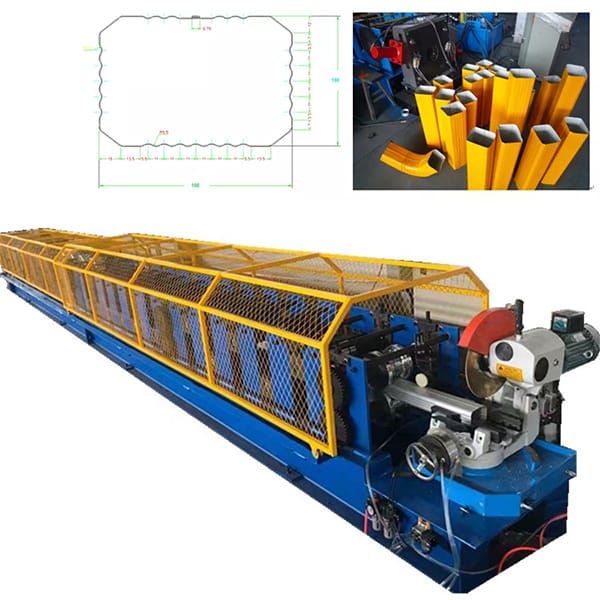

Good quality rain gutter downpipe gutter and elbow roll forming machine

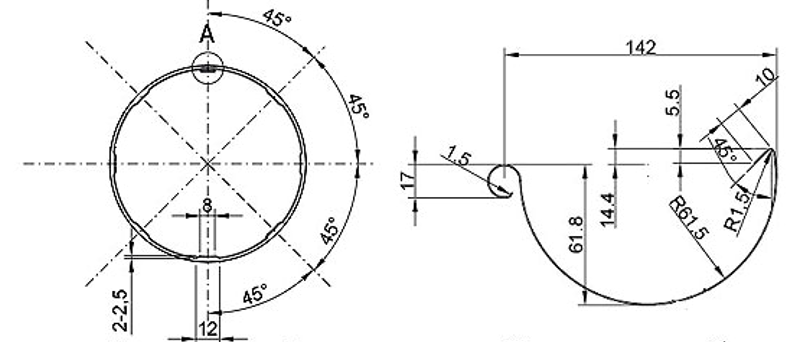

Downspouts are most commonly seen attached to the corners of home or building. Without perfectly working downspouts, rainwater will fall off the roofs edge and may cause flooding and damage to the building. Rain water will pass through the cracks in the walls, windows and into the buildings foundation.To make quality downspouts, you need quality roll forming machines to make them.Zhongtuo downspout pipe making machine could be used to make downspout pipes in a higher speed and good quality by 16 years in this area. For this machine, we take guide column frame style to make machine for making sure machine working speed and steady. And for the transmission, we will use gearbox with chain. Here are some random drawing profile for your reference. Before sending the accurate quotation to you, we need to know the accurate sizes and drawing profile like this:

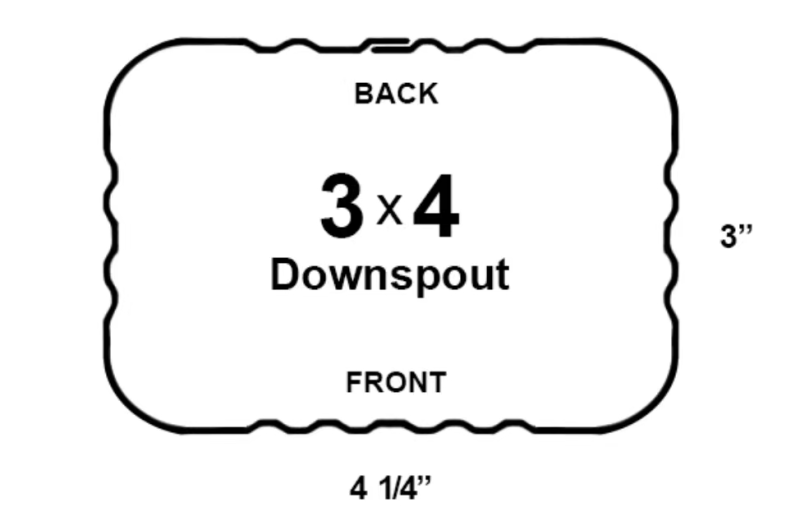

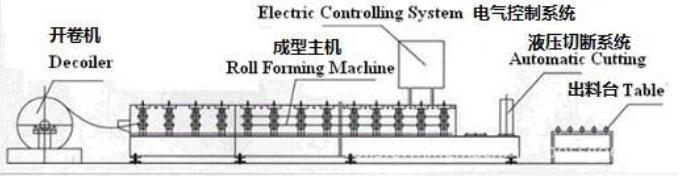

Our downspout roll forming machine mainly consists of uncoiler, roll forming system, cutting equipment, protective guard, hydraulic system, control system and out table. It can make curve for down pipe to meet the requirement of practical engineering projects. And also in the market, there is square type for example:

Machine components

Passive uncoiler, Guiding unit, Roll forming machine, Cutting unit , Hydraulic station, PLC control cabinet, Supporter table, Security cover, Elbow machine

Technical process

Passive uncoil— Feeding—Roll forming—Cut to length—Output table—Elbow with pipe

Technical parameters of the rain pipe machines.

Items | Specifications |

Material Spec | Galvanized steel sheet, color sheet |

Thickness of Coil Sheet | 0.3 –0.8mm |

Main Motor Power | 5.5kw |

Forming Speed | 10-15m/min |

Hydraulic Station Power | 3kw |

Quantity of Stands | 18 |

Hydraulic Pressure | 10~12Mpa |

Controlling System | Panasonic PLC |

Index Error of Length | 10m±2mm |

Total Weight | 7T |

Voltage | 380V 3 phase 50Hz |

Square rain tube rolling forming machine working videos for your reference: