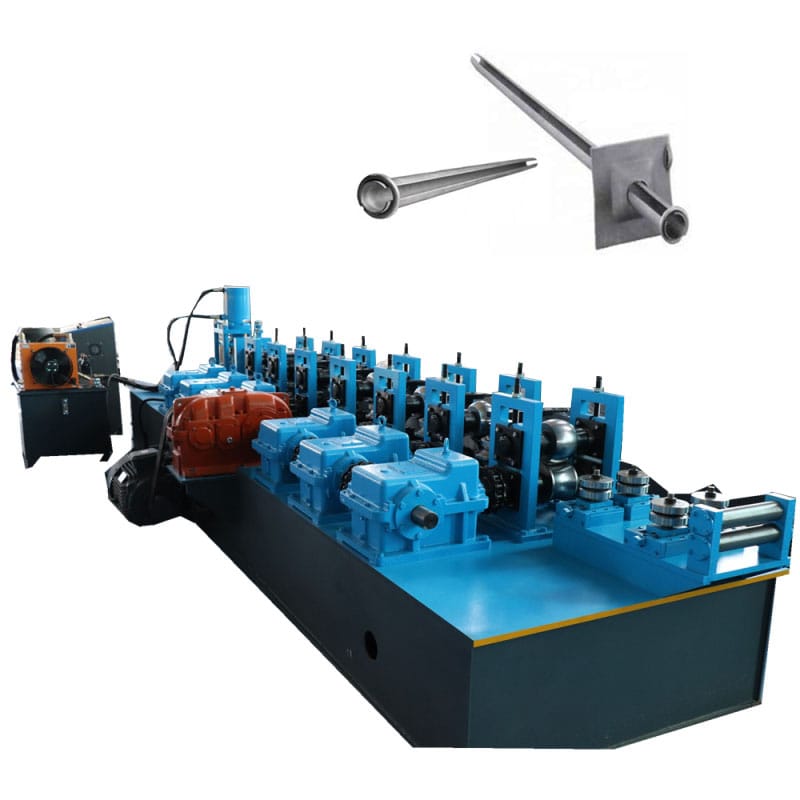

This machine can produce the mine rock bolts , if there is a punching one the end for Shrinking , the speed will 20m/min. if don't have the punching the product, the max speed can up to 40m/min.The whole set machine including main rock bolts roll forming machine, 3 ton manual decoiler , manual receiving table, Shrinking machine.

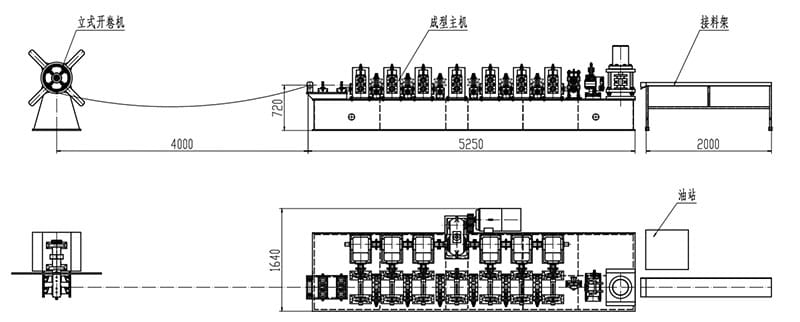

Process flow drawing:

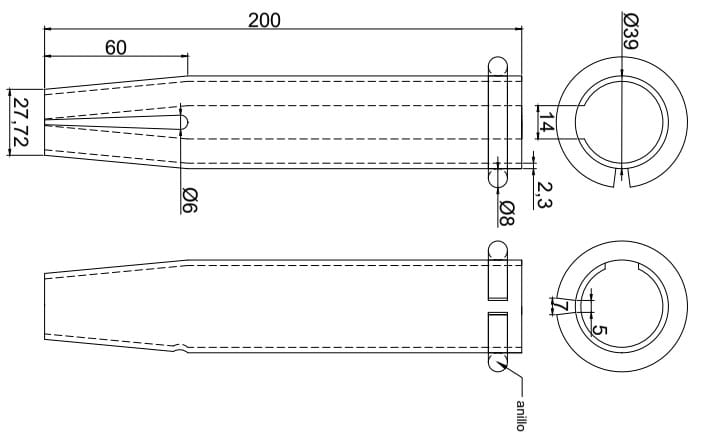

The Mine Anchor profile for reference:

There is also notch for shrinking:

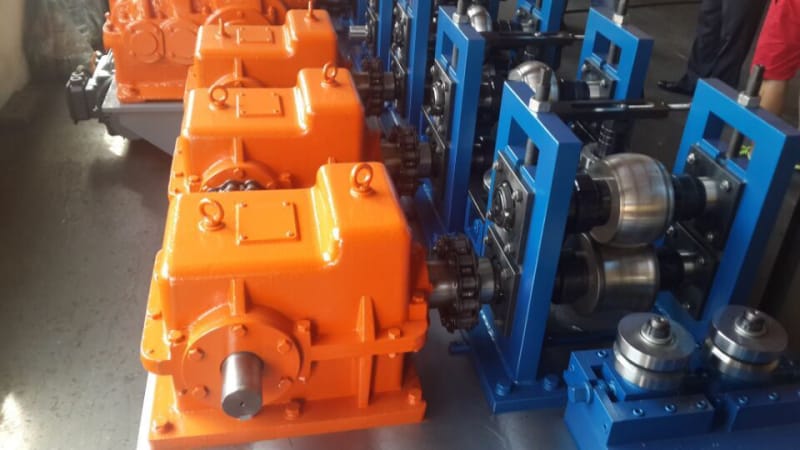

The machine can process 3.5mm thickness material, So the machine must be strong , we use gearbox for transmission.We will design the machine like this:

Anchor roll forming machine part list:

No. | Name | Unit | Quantity | Remark |

Part 1 | 3T decoiler | set | 1 | Manual |

Part 2 | Main roll forming machine | set | 1 | 30m/min |

Part 3 | PLC control station | set | 1 | Mitsubishi brand |

Part 4 | Cutting system | set | 1 | Hydraulic |

Part 5 | Hydraulic station | Set | 1 | 45# oil |

Part 6 | Product table | set | 1 | Regular |

Technical parameters:

Shaft material: 45# STEEL

Shaft diameter:70 mm

Roller material: GB-Cr12

Rolling station No. :7 stations

Work speed: 20m/min

Machine frame: Vertical arch frame structure

Motor power: 15 KW

Transmission: By gear box

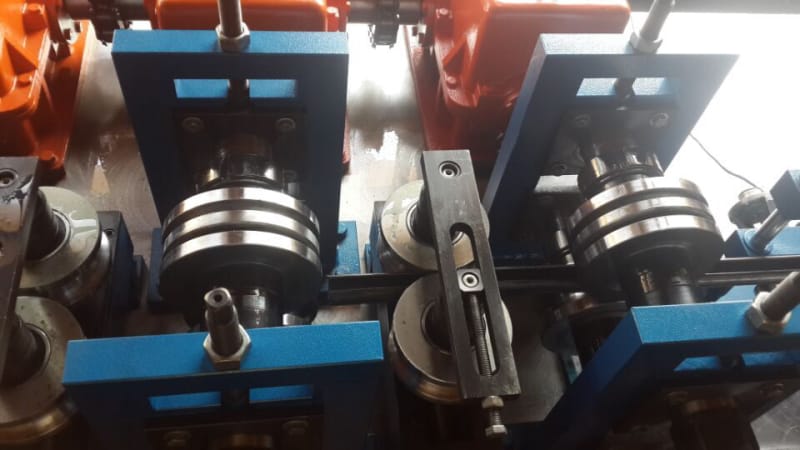

Machine details :

Rollers

Gear Boxes:

Shearing system

The shearing system punching and cutting together, we need use mould- cutting for this machine , this waste the time for production, the speed only 20m/min. If use the tracking cutting the speed will be increased to 40m/min.

Shrink machine:

About the Shrink machine the operation is so easy, just use the foot to push the switch, Hydraulic station will provide the power, and mould press the end of tube to finished the shrinking.

Shrink machine picture for reference:

This is the video for metal rock bolts making machine instruction

Contact information:

Email: cnzt011@zhongtuocn.com

WhatsApp Nuber:+86 18631755623

Contact person: Lee