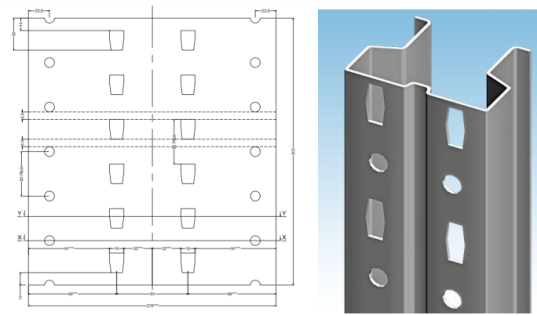

Description:Shelf uprights are crucial for the safety and efficiency of a detachable shelf system. They are made of cold-formed punching thin-walled steel and have a residual processing stress. The design and selection of uprights are essential for the overall shelf system’s safety and eff iciency The assembly of shelves consists of basic parts like uprights, beams, and optional accessories. The shelf upright’s stability is influenced by the physical properties of the materials used, mold design, and manufacturing accuracy.

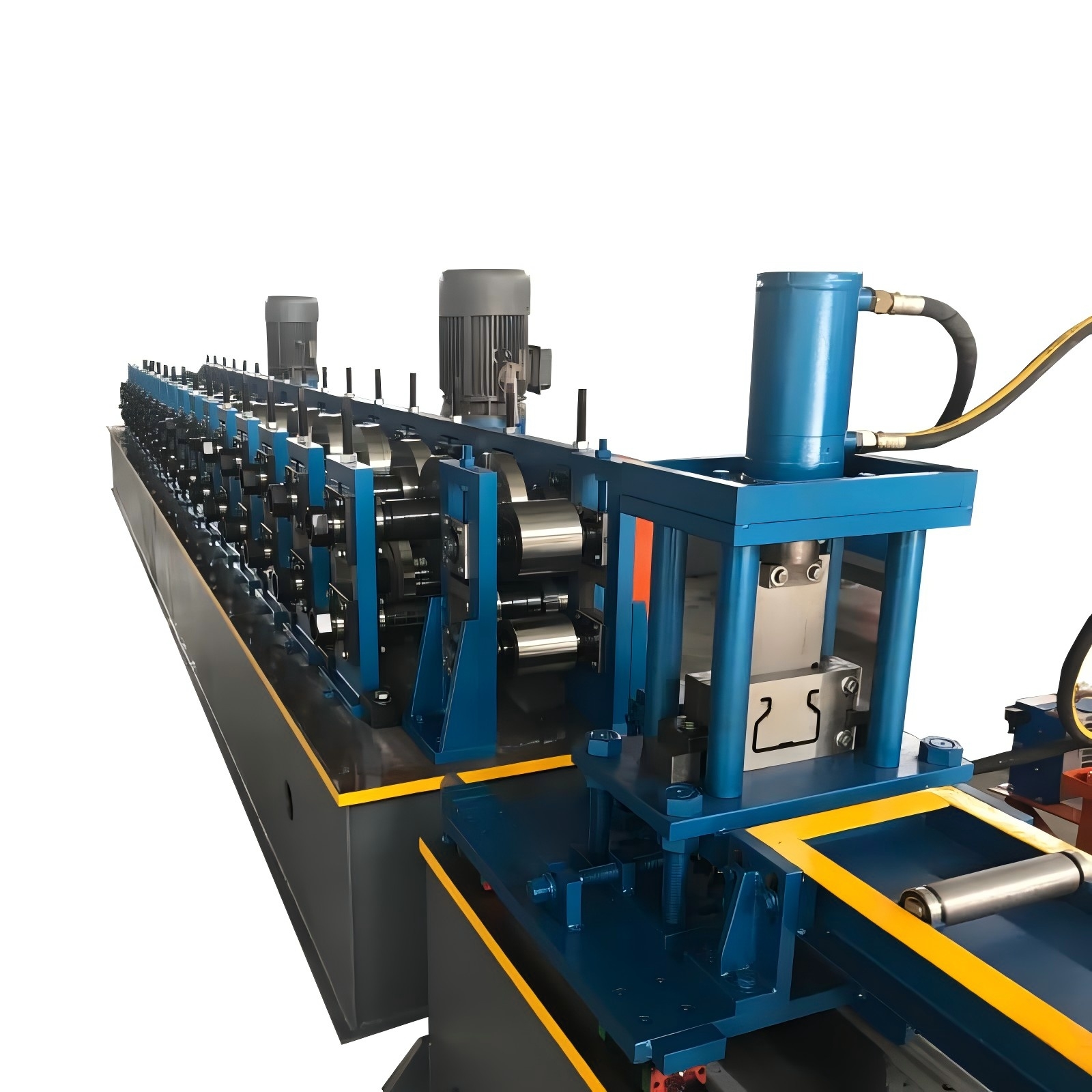

Shelf System Steel Upright Rack Making Machine

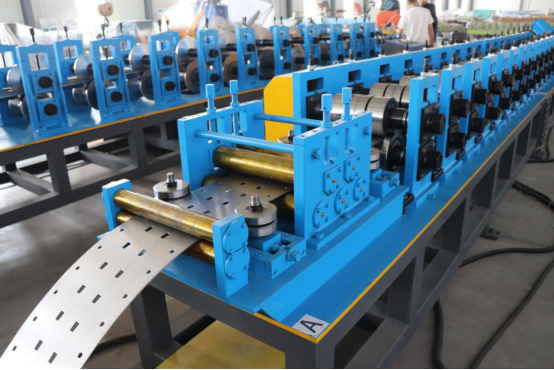

The Shelf System Steel Upright Rack Making Machine is built with cutting-edge technology to ensure precision and accuracy during the roll forming process. With constant precision and great efficiency, cut sheet metal into diverse profiles. The feeding and straightening units, roll forming stations, punching and cutting systems, and control systems are all included in the Upright Roll Forming Machine.

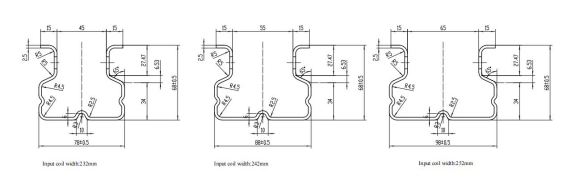

The required profile drawing: material thickness 2.0 to 2.5mm

About the punching part: better you can give me the exactly design you like.

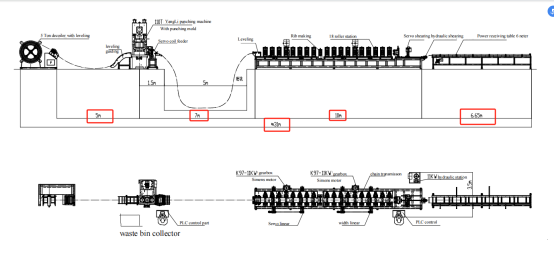

The work flow for upright rack forming machine

Shelf System Steel Upright Rack Making Machine

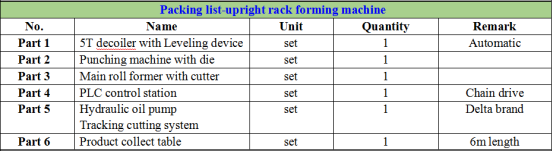

Packing list-upright rack forming machine

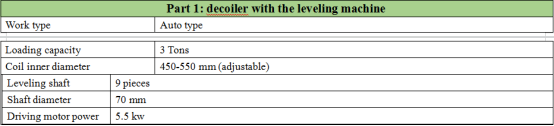

Decoiler with the leveling machine

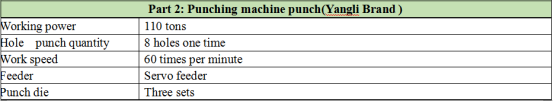

Punching machine punch(Yangli Brand )

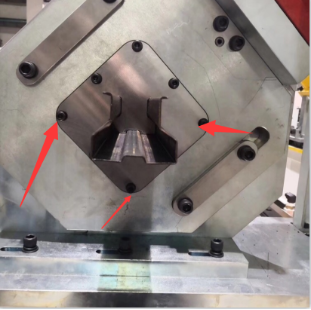

About the punching mold design:

1 set combined mold can be used for 3 sets of sizes. By adjust the mold in and out with handrail.

This price contains one working and one spare part

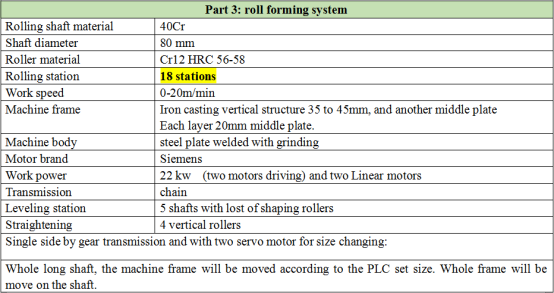

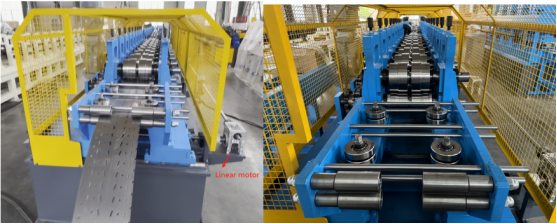

Roll forming system

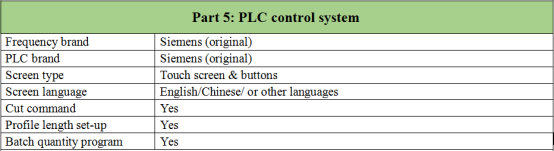

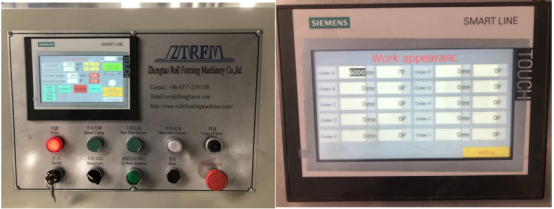

PLC control system

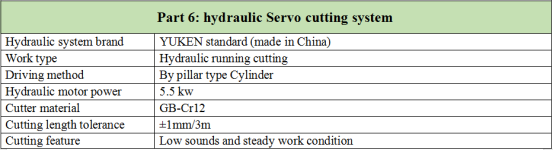

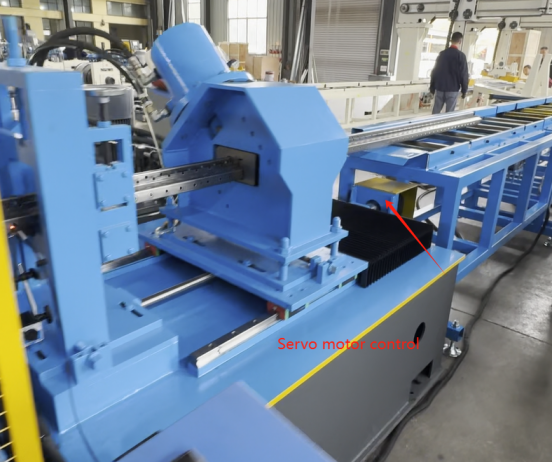

Hydraulic Servo cutting system

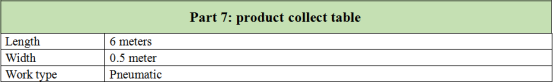

Product collect table

How to change the cutting blade for different sizes?

For different sizes, please change the cutting blades here.