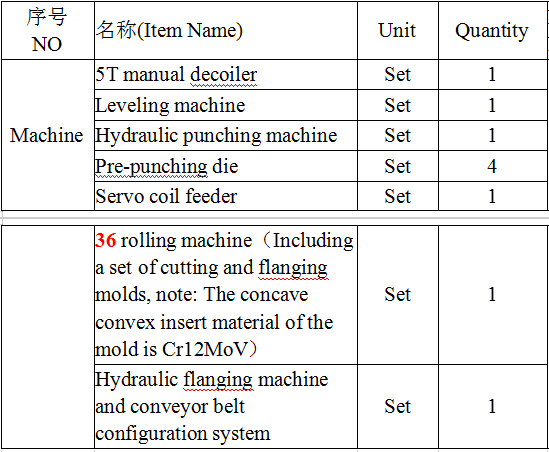

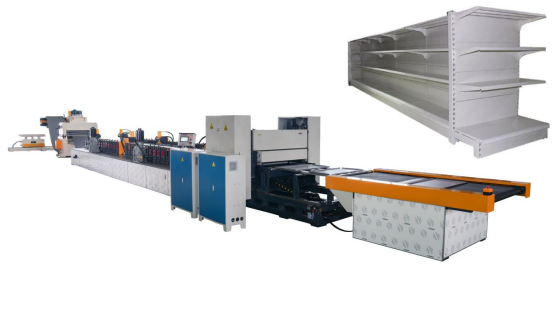

Slotted Shelf Racking Pallet Roll Forming Machine

The Slotted Shelf Racking Pallet Production Line serves diverse industries that require high-performance storage solutions, including warehouse management, distribution centers, manufacturing facilities, and logistics operations.

It caters to the demand for reliable and versatile pallets to optimize storage space utilization and streamline material handling processes.

Product Detail

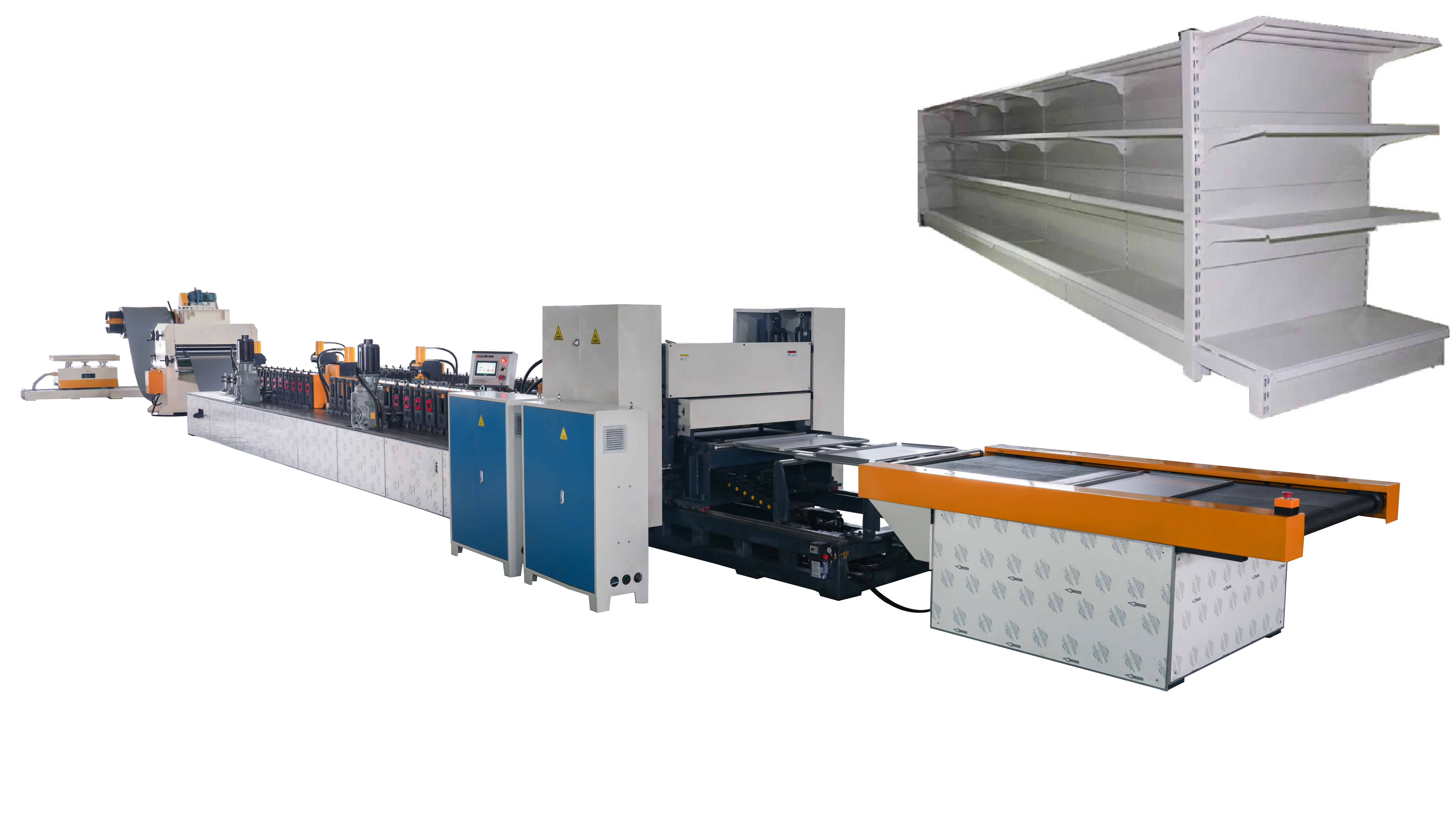

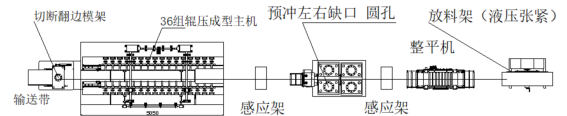

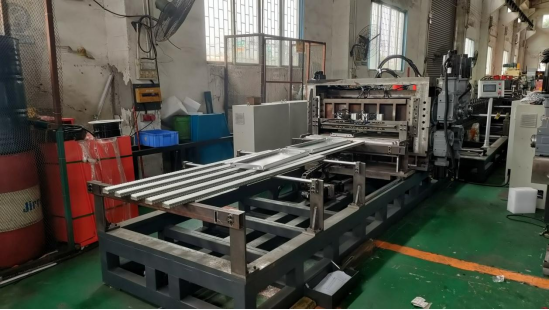

Production Process

5T manual decoiler → 1000mm leveling machine → 1000mm servo CNC feeding machine (Huichuan servo 1.3kw)+2 notches+2 left and right circular hole hydraulic front punching machines (2 mold bases, 4 sets of molds) → 36 sets of width adjustable rolling forming (main drive 15KW variable frequency speed regulation, CNC width adjustment, Huichuan servo 0.85KW) → hydraulic cutting and flanging (1 set of mold, 7.5KW oil pump motor) → discharge conveyor belt (motor 0.2kw).

Slotted Shelf Racking Pallet Roll Forming Machine

Features

1. Convenient, easy and quick operation.

2. High arruracty of finished products, no scratches or cracks.

3. Widely used in shelving and racking industry.

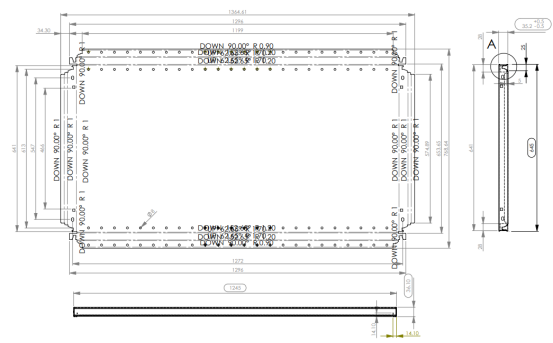

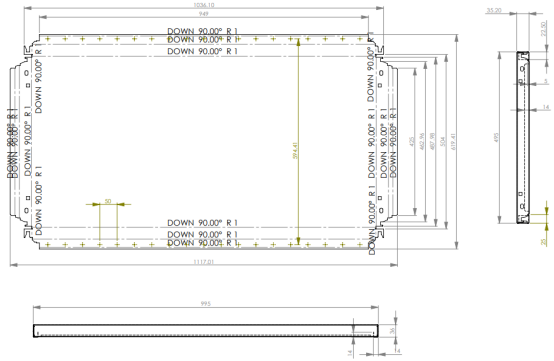

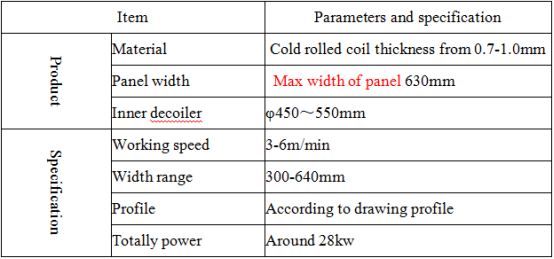

DL-M50-20-500 width adjustable production line parameters:

More details

1.Material rack:with a capacity of 5 tons and a coil inner diameter φ 450~550mm, with the maximum outer diameter of the coil material φ 1300mm, passive discharge.

2.Leveling machine:feeding width 500-1000mm, using a 1000mm leveling machine with 3 upper rollers and 4 lower rollers, and 2 sets of pinch rollers. Leveling roller diameter φ 50, diameter of pinch roller φ 58.

3.Servo feeder:feeding width 500mm, servo motor 1.3kw, feeding speed 15-25mm/min, high-frequency treatment of pinch roller for hard chromium plating

4.Front punching mold base:1 15T hydraulic mold base, pre punching the notches on both sides, 2 sets of molds (1 set on each side).

5.Feed guide mechanism: ensures that the material does not deviate when entering the roller for rolling.

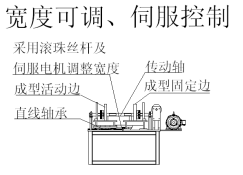

6.Rolling forming part:Formed using 36 sets of rollers, the roller material is Cr12MoV, vacuum heat treated, and the hardness is HRC55-58.

Main shaft diameter φ 50. The material is 45 # steel, which is made by rough machining, quenching and tempering, fine turning and fine grinding.

Two sets of tapered roller bearings 30209 are equipped on the transmission side, and one set of cylindrical roller shaft NJ209 is equipped on the operation side.

7.Transmission:Main motor 15KW (gear reducer) variable frequency speed control.

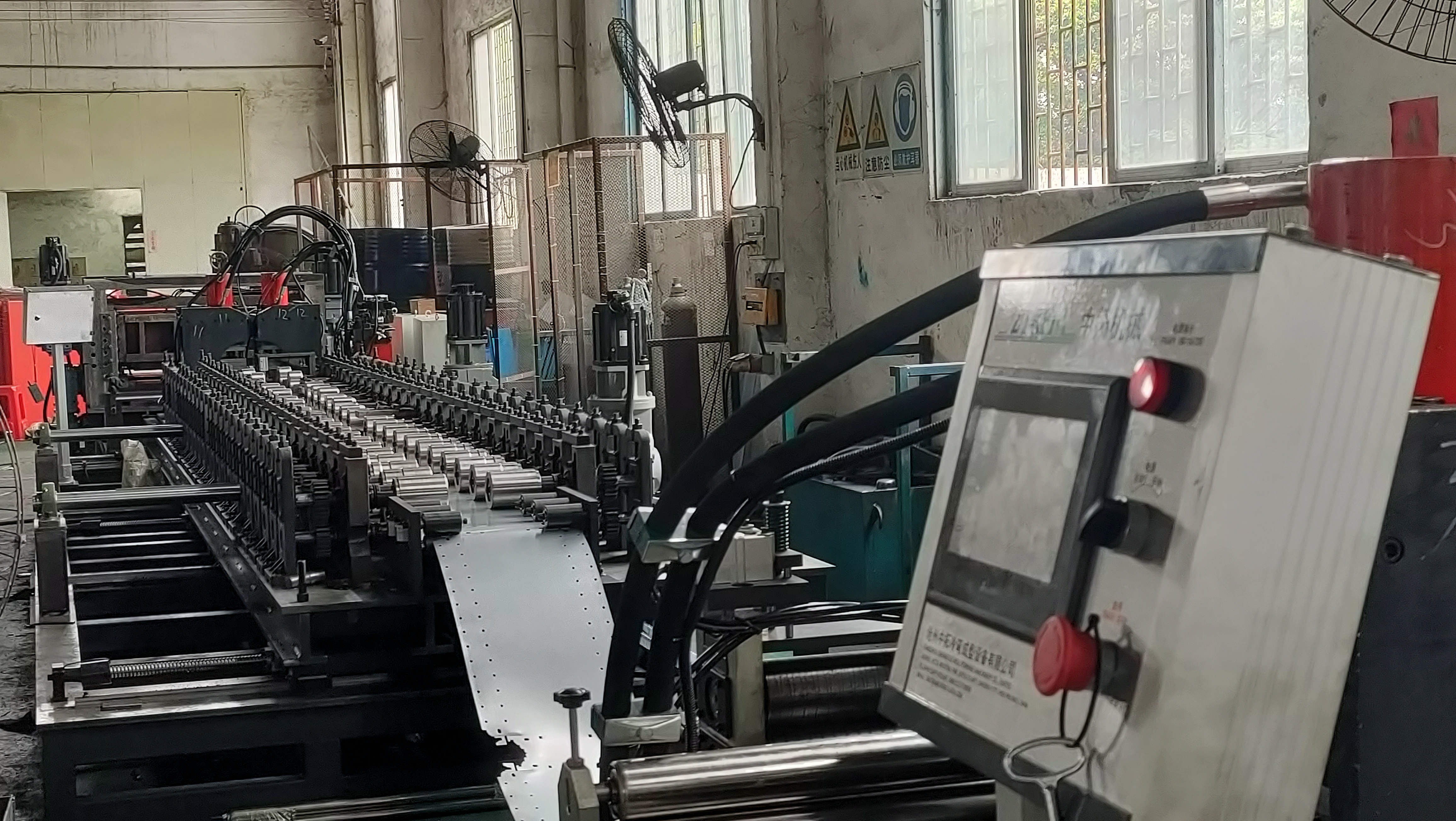

8. Hydraulic cutting and flanging system:The system has unloading protection function and a 25 ton hydraulic cylinder structure.

9.Convey table 2 meter

10.PLC control system:Adopting Huichuan servo CNC system and Mitsubishi programmable PLC from Japan; Shenzhen sine frequency converter speed control centralized automatic control; Set parameters using the Xinjie touch screen.

The entire production line adopts centralized automatic control, with linkage between the forming machine and the flanging and bending.

Alarm function: There are alarm functions such as material shortage shutdown, counting, output reaching shutdown, emergency stop, mold clamping, limit position, etc

11.Pneumatic components:The main pneumatic components adopt the Taiwan famous brand AIRTAC

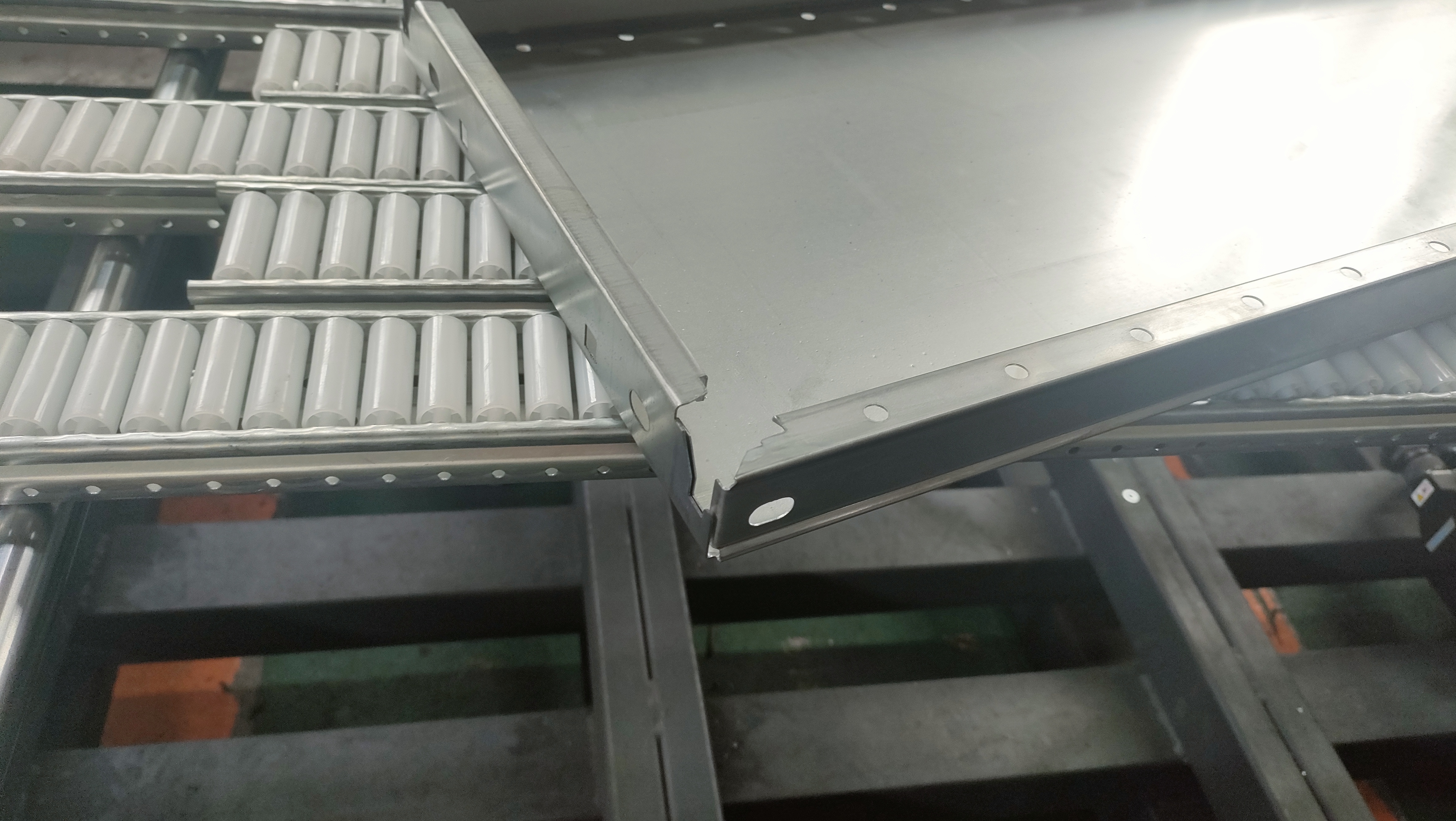

Items