Description:The storage rack system is composed of finished products by 4 sets of roll forming machines, Upright roll forming machine, Beam roll forming machine, C support roll forming machine and Lock roll forming machine. Upright roll forming machine can product material thickness up to 3.0mm, adopt continuous servo punching machine to make punching speed fast and more accurate. Beam roll forming machine can roll material from 1.0mm to 4.0mm, and the web size can adjust from 60mm to 180mm by automatically.

Box Beam Roll Forming Machine

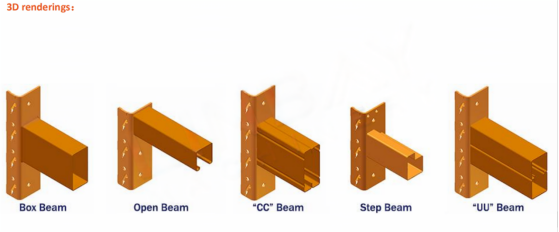

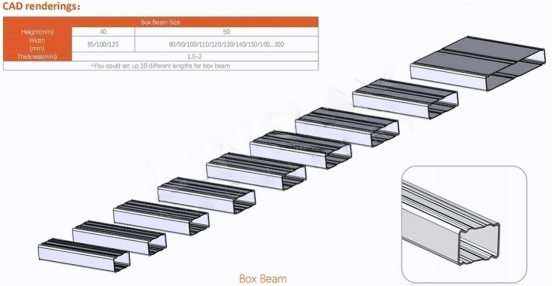

Pallet upright rack roll forming machine is widely used in producing upright frame, box beam and step beam. Our intelligent roll forming machine could make wide range of sizes using cantilever type structure, and automatically change by motors from one size to the other not only at width but also at height. The one and only step is to put your required data into our touch screen and wait for few seconds. Machinable thickness is from 1.5-3mm with raw material Cold-rolled Steel, Galvanized Coil, PPGI, Carbon steel, Stainless Steel and Aluminum. Our produced profile meet ISO, CE , FEM standards, and our machine is applied to Warehouse ,supermarket ,industry or home.

We make different solutions according to customers’ drawing, tolerance and budget, offering professional one-to-one service, adaptable for your every need. Whichever line you choose, the quality of ZTRFM will ensure you obtain perfectly functional profiles.

Application

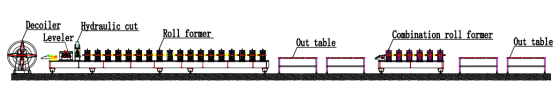

Machine Production Process

Box Beam Roll Forming Machine

Main Technology

· Heavy duty uncoiler with coil car

· Continuous punching machine

· Full automatic change size

· Non-stop high speed cutting

· Full automatic stacking and packing

Product Parameter

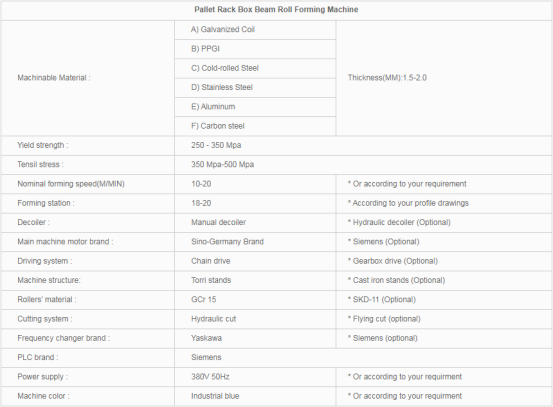

Technical Specifications