Gutter Cold-Roll-Forming Machine

Machine item

There are two types of machines in the list. First, there is 1 set of 3 t manual decoiler, which is to be shipped in a 40 - foot general - purpose (40GP) container with the price term of F.O.B. Second, there is 1 set of Rain gutter Machine, for which the container information and amount details are yet to be filled.

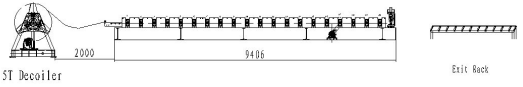

layout drawing

flow chart

The main components include:

1. 1 Set of 3T Manual Decoiler (3 Ton uncoiler);

2. 2 Pieces of Guiding Rolls (inlet rolls);

3. 1 Set of Pre - cutting/Feeding Platform (pre - cutting platform);

4. 1 Unit of PLC Control System;

5. 1 Unit of Hydraulic Pump Station;

6. 1 Set of Hydraulic Cutting Device;

7. 1 Set of Manual Receiving Table.

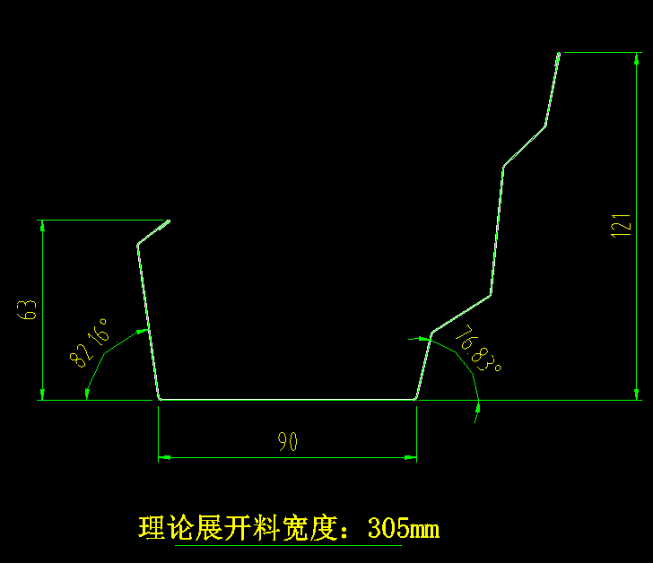

Raw Material

1. Material: Pre-Painted Galvanized Steel Coil

2. Material Thickness: Coil thickness: 0.3 - 0.7mm

1.1 3 T Manual Decoiler (Manual Uncoiler)

· Loading Capacity: Max 3000KG

· Suitable Coil Core: 508mm

· Suitable Coil Width: 500mm

· Frame Structure: Square Pipe & C-Beam

· Shaft Diameter: 70mm

· Bearing Type: 6210

1.2 Pre-cutting Device & Platform

· Frame Structure: Steel plate welded and screwed

· Platform Function: Bearing press the metal plate for smoothly feeding

· Extra Function: Easily to pre-cut the plate while change different steel coils

· Pre-cutting Blade: Cr12Mov

· Feeding Roll: 2 units

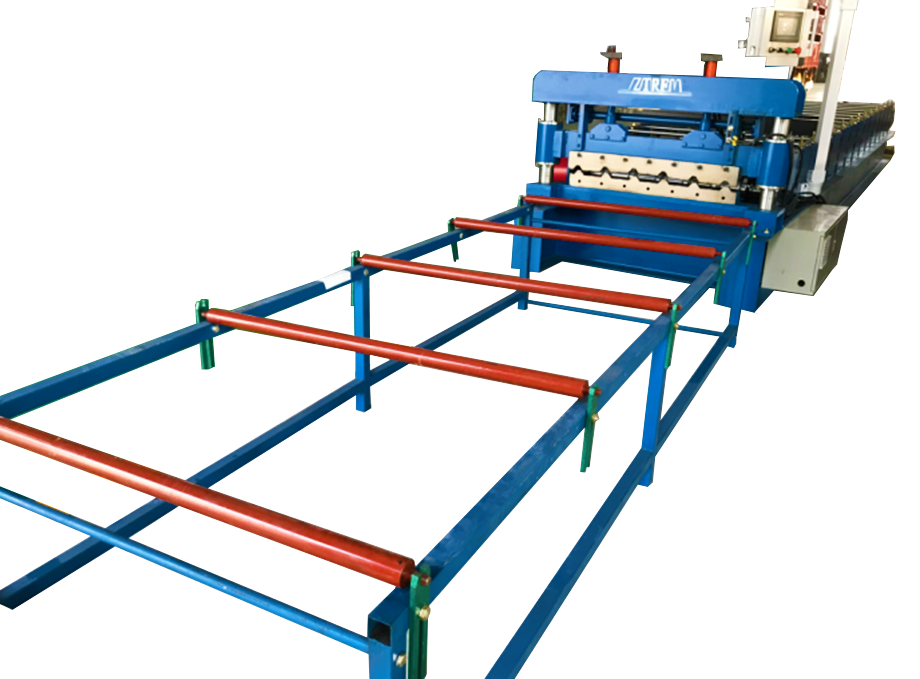

1.3 Roll Forming Machine

· Base Frame Structure: 350 H-beam welded

· Sidewall thickness: 16mm A3 Carbon Steel seamless welded with base frame

· Roller Stations: 18 forming units

· Connect Bar: Diameter 25mm galvanized steel rod

· Roller Shaft (Solid): 70mm-0.01~-0.03 with Key-way

· Shaft Material (Hard): High grade 45# steel,lathe then polishing smoothly

· Roller Material (Hard): High grade 45# steel,CNC lathe then chromed plated 0.05mm

· Bearing type: standard 6210(Wanxiang,Wuxi), single units inside wall box

· Screw and bolts: Common 8.8 standard

· Transmission method: 0.6 inch (Jindun,Hangzhou)

· Driving motor: 4.0KW(Lichao,Shanghai)

· Motor reducer: 4.0KW (Wujin,Changzhou)

· Forming speed: 10-12m/min

· Cutting Tolerance 10M±1.5mm

1.4 PLC Control System

· PLC System: Delta PLC Programme, Taiwan

· Encoder Brand: Rongde, Changchun

· HIM Screen: Detlta, Taiwan (English-Chinese)

· Inverter Brand: Delta , Taiwan

· Other Electronic: +/-24V low voltage CHNT

1.5 Hydraulic Pump Station

· Main Function: Supply power for hydraulic cutting processing

· Pump Station: 3.0 KW(Lichao, Shanghai)

· Solenoid Valve: ±24V(Huade, Beijing)

1.6 Hydraulic cutting Device

· Frame Structure: A3 Carbon Steel Plates welded & Guide Pillar

· Working Method: Stop to post, and post to cut

· Cutting: Inside sealing Cu Spacer, whole life no maintain,only inject oil

· Cylinder Quantity: 1 Unit

· Cutting Blade: Cr12Mov

· Cutting Tolerance: 10M±1.5mm

1.7 Manual Receiving Table

· Production Length: 3000MM

· Production Width: 500mm

· Control Method: Manual receiving

· Frame Structure: Square pipe & screws, roller moving

· Necessary Spare Parts:

· Relay: 2 pieces

· Control Button: 2 pieces

· Counter Wheel: 1 piece

· Limit Switch: 2 units

· Bearing: 2 pieces

· Chain: 2 pieces

· Oil pipe: 2 pieces