ZT 1000 profile High Speed roll forming machine

What is ahigh-speed roof tile forming machine?

The high-speed roof tile forming machine is a kind of high-efficiency equipment for manufacturing roof tiles. It uses metal coils as raw materials and, with the help of automated roll forming technology, can continuously process the coils into various types of roof tiles, such as corrugated tiles and flat tiles.

It has an astonishing production efficiency, capable of producing roof tiles up to 40 meters in length per minute, which greatly increases the production capacity. At the same time, the equipment is highly automated and can operate stably with only a small number of workers for operation and monitoring. The produced roof tiles are of precise dimensions and reliable quality, and are suitable for the roof construction of various buildings, including industrial plants, civil residences, warehouses, and other scenarios.

Details of the Machine

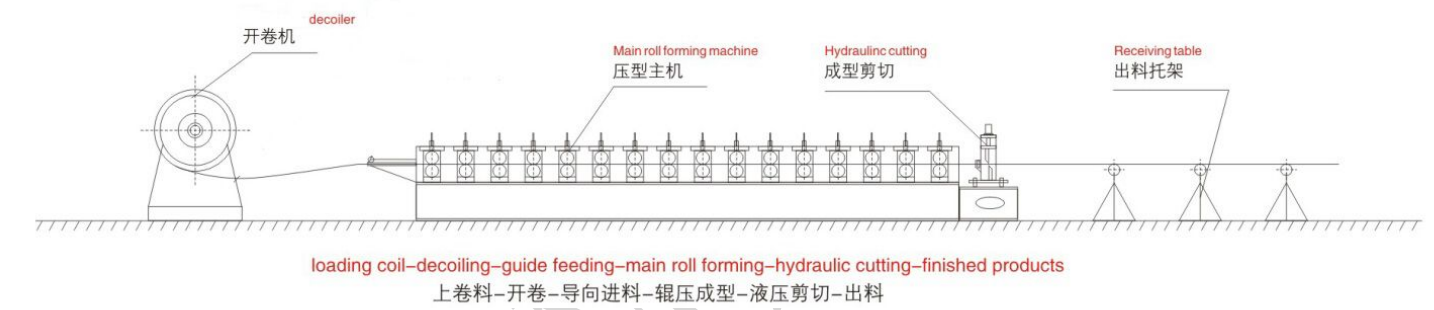

1.Processing flow diagram of machine

2. Technical parameters of the 1000 High Speed roll forming machine

The equipment include:

1. Hydraulic Uncoiler with car …………..... 1 set

2. Feeding cutting………………………..… 1 set

3. Roll forming main machine………………1 set

4. Hydraulic cutting………………………… 1 set

5. Hydraulic station………………………… 3 sets

6. Electric controlling system…………...… 1 set

7. Product rack .......................……………… 1 set

8. Instruction Book………………….……... 1 piece

Requirements:

Corrugated sheet roll forming machine

Material: HR, CR, G/Z,PRE-PAINTED COILER

Thickness: 0.28-1.0mm

Roll forming speed: 40M/min(max speed by fly cutting)

Total power: 85 HP

Voltage 380v/ 60hz / 3ph

SPECIFICATIONS:

1. 10 TON HYDRAULIC UNCOIER WITH LOADING

* MAX LOADING 10 Ton

* MAX Coiler Width 1250mm

* Coiler Inner Diameter 450-550mm

* Max coiler outer Diameter 1600mm

* Five segement hydraulic uncoiler 1 set

* hydraulic system 1 set motor 7.5HP with oil tank ,100 liter

* Control box 1 set manual/auto switch

(uncoiler clockwise & counter clockwise remote control auto sheet sensor for feeding)

* Max coiler outer Diameter 1600mm

* Coil car 1 set, max loading 10 TON

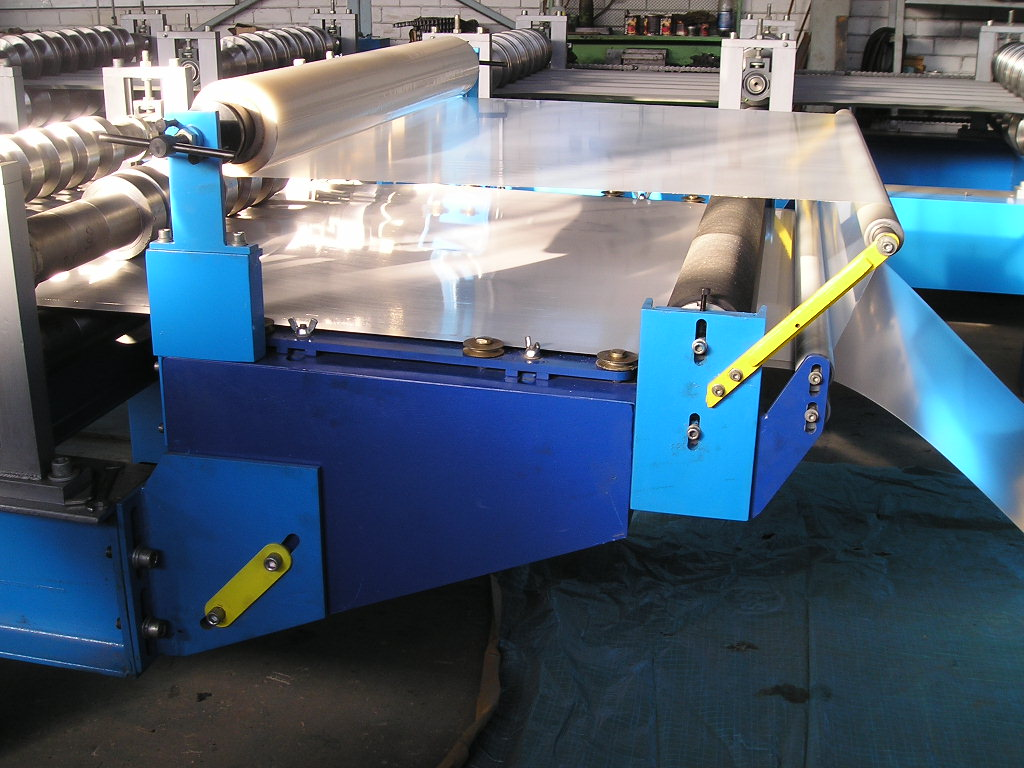

2. FEEDING CUTTER

*CUTTER: 1 set,muterial SKD-11 with feeding harden HRC 58-60 ℃

*Hydraulic cylinder Φ100 type, for coiler change use

3. ROLL FORMING MACHINE

* Sheet feeding guider 1 set

* Roll forming station 24 stations

* Roll forming speed 40 M/min (max speed by fly cutting) VARIABLE SPEED (FREQUENCECY CONVERTER)

* Thickness range 0.28-1.0mm

* Roll forming shaft Φ85 mm material S 45 C with harden and grinding & hard chrome plating

* Transmission type : Double Bevel gear box drive

* Length setting by encoder 2 set

4. FORMING CUTTER

* Forming cutter 1 set, material SKD-11 with harden HRC 58-60 ℃

* Hydraulic cylinder Φ 125 type

* Flying cutting servo motor 5 HP

5. CONTROL BOX

* Touch NC-PLC setting, with touch screen, can set length , quantity one time can set 99 sets non stop cutting, cutting tolerance 2.0 mm, with fan cooling system

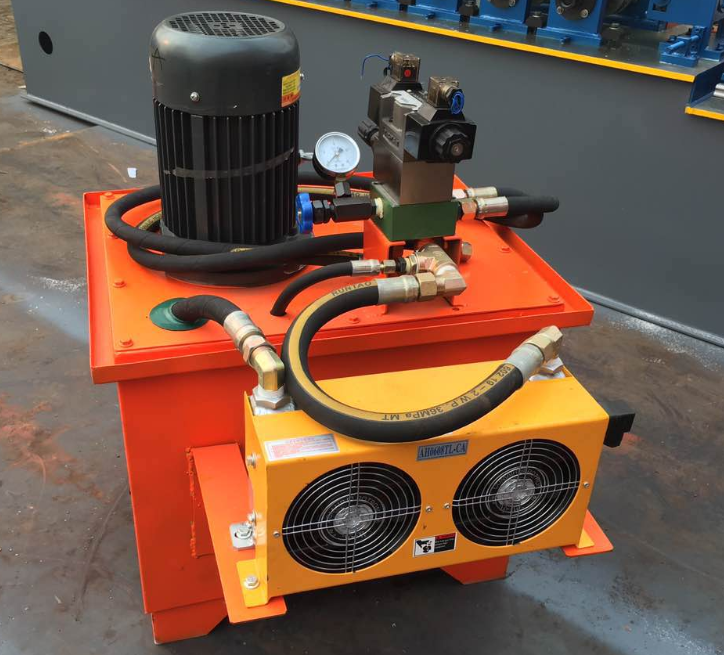

6. Hydraulic system

* Main motor not less than 100 HP types SIMENSE

Attach refrigerations oil cooler capacity not less than 2 KW to reduce hydraulic oil temperature

* Oil tank Capacity 500 liter

Oil pipe all use high press pipe

7. 12 M AUTO STACKER WITH 3 M SIDE CONVERYOR & AUTO LEVELING

* Length 12 M

* Side run-out conveyor 6 SET

* Side run-out conveyor length 3 M

* Double side air cylinder drop corrugate sheet

* Back side with auto leveling corrugated sheet

8. Other Spare part

Weight About 15 ton

Function Automatic length and quantity measurement

Dimension 15000*2200*1700mm L x W x H

Main body color As required

Voltage 380v/60hz/3ph

Spare cutting blade One piece for profile

Fuse 2 pieces

Relay 2 pieces

Travel switch 2 pieces

Solenoid valve 1 pieces