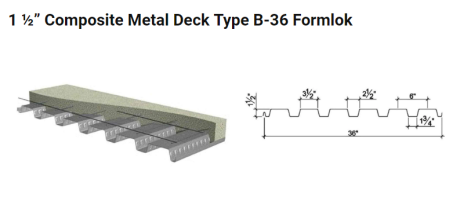

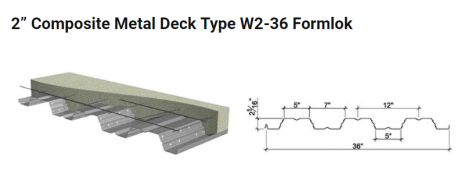

Metal floor decking sheet is also called as composite metal floor decking which is metal floor deck with an embossing pattern manufactured into the sides (flutes) at regular intervals. The embossing pattern allows the concrete to bond with the metal decking panel as the concrete cures. The main difference between a floor deck and a roof deck is that roof deck does not have the embossing pattern and then thickness will be a little thin that this type.

About the overlap of metal decking sheet:

Composite Metal Floor Deck can be manufactured with 2 different types of side laps. It can be made with the standard interlocking side lap or a screw fastened side lap.The most common side lap connection type specified on composite metal floor deck is the standard interlocking side lap. It allows the side laps to be connected by Button Punch, PunchLok, or Top Seam Weld. The project plans will specify how the side laps will be connected. Let us check details from the above drawing.

Advantage of Composite Metal Floor Decking

1. Added strength. Embossing pattern allows the concrete to bond with the metal decking panel as the concrete cures.

2. Lighter in weight: The weight of a non-embossed panel and an embossed panel is identical. However, when you add extra weight, you have to account for it in multiple areas. That makes the value of embossed panels much higher when you’re looking to strengthen your floor system.

3. Adding logo. If you need, we can also add logo for the metal decking sheet.

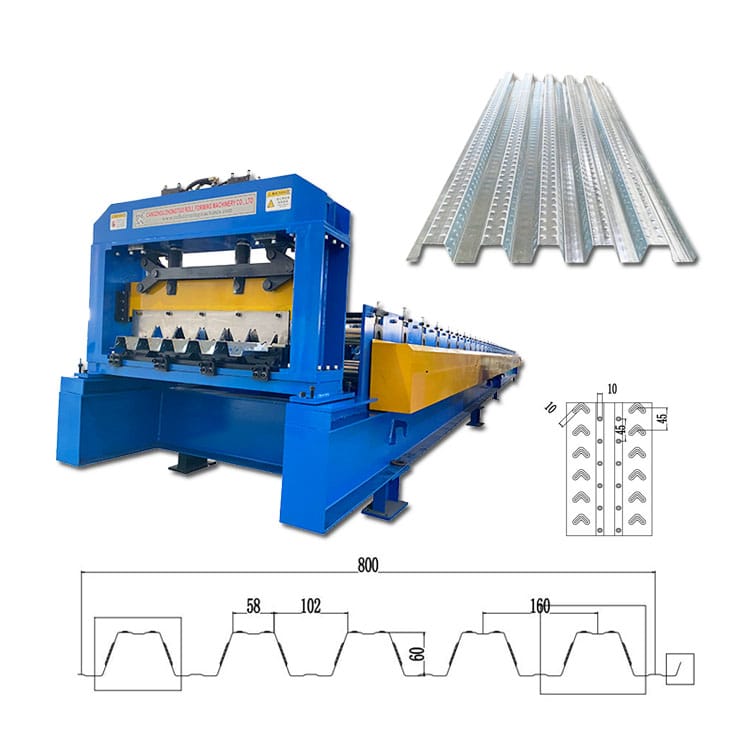

Metal floor decking rolling forming machine:

Features of Metal floor decking rolling forming machine:

1. Customize: Metal decking machine can produce a variety of specifications of the floor bearing plate, can also be customized according to the customer's requests, to meet the needs of all customers, electricity.

2. High efficiency: our metal-making machine possesses the production speed of up to 25 m/min. The embossing type is adjustable with brake.

3. Universal parts rate are high, simple maintenance.

4. The enhanced design of the mainframe structure and quality control allows our metal roll forming equipment to produce thicker plates for you.

5. AII the processing of the frame is completed at one time, and the advanced machine tools ensure the accuracy of the size and position of each fit so that our molding unit almost does not need repeated debugging, with very ltte dependence on personnel.

6. The automatic program control technology is adopted. The parameter setting of the metal deck roll forming machine is simple and convenient, and the degree of automation is high. The system's self-learning ability is strong, and the control system uses the high-quality brand. In addition, the man-machine interaction interface is also very user-friendly.

Welcome both national and international customers to contact us for more information on the steel deck floor roll forming machines. Here is the machine working video for your reference: