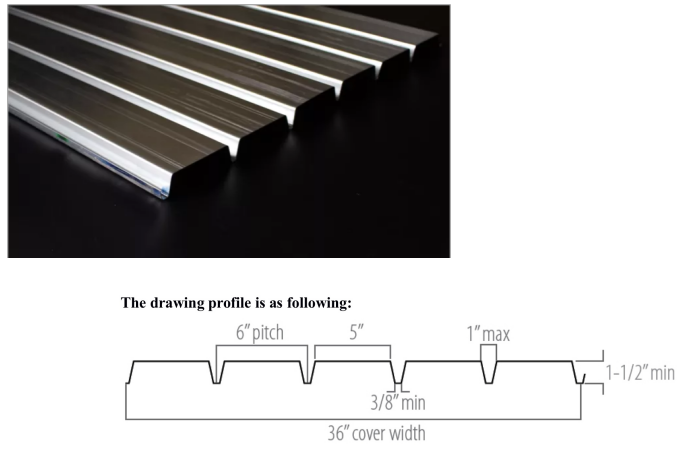

Description:Type A roof deck is the “original” term for this deck profile, though recently the Steel Deck Institute has promoted the more descriptive name, “Narrow Rib Roof Deck”, or “Type NR”.

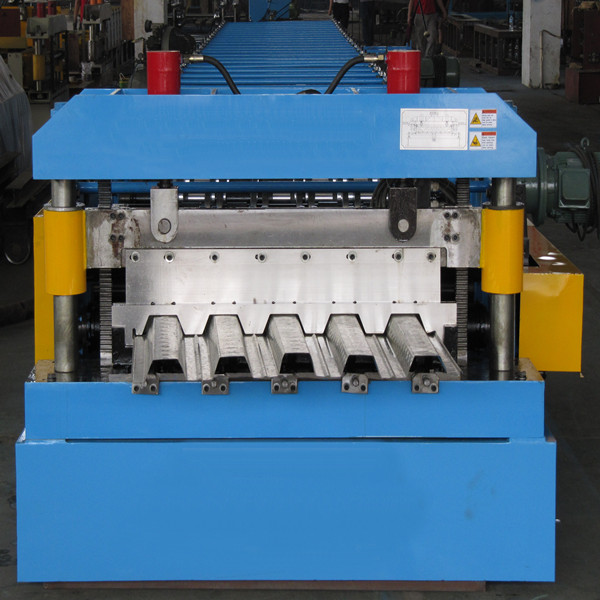

Type A Roof Deck rolling forming machine

Unlike other types of metal roof decking, Type A roof deck is rarely used for new construction projects, but is often needed for repair and re-roof projects. This is due to the fact that Type A roof decking is the least efficient 1.5” deep steel roof deck section. Compared to Type B and Type F roof decks, Type A metal roof decks have the lowest strength-to-weight ratio. As with all steel products, the lighter the section, the more economical it will be. And since Type A roof deck cannot carry as much load at longer spans as B deck and F deck, the steel supports below the metal deck must be spaced closer together. In turn, a smaller support spacing results in more supports and higher costs for the building owner.

Here is one drawing profile and finished product:

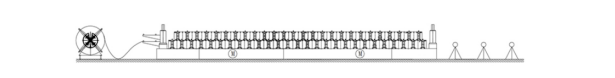

Type A steel roof decking rolling machine Work Flow :

5T Hydraulic Decoiler-→Manual Pre-Cutter Device- + Feeding Guide Device-→Roll Forming System- >Hydraulic Post Cutter Device-→AUTO Exit Rack

Type A Roof Deck rolling forming machine

Advantages of Metal Floor Deck Machine are as follows:

1.Floor decking sheet produced by this machine has the features of low cost , light weight buy high strength ,shorten building period and re-cycle use .

2.Save material with no waste

3.Easy operation , low maintenance cost

4.It is easy for installation.

Feeding Device

1.There are 2 rollers at the feeding device, which can be rotated to reduce the friction of the feeding and avoid scratches on the surface of the material.

2.Touch stainless rollers can make the material go into the machine smoothly and prevent the scratch on the material surface.

3. With a hand wheel to adjust the feeding width, making the feeding more accurate.

Roll Forming Device

1.rollers Gcr15 quenching treat HRC58-60 good hardness for long service time.

2. Each roller has number and with keynotes, it can fix on the shaft stablely

Our machine use very thick material to manufacturing the machine basic frame, ensure very stable when it running. The machine especially add diagonal bracing to make sure stability.

Automatic Shearing System

1. The cutter is constructed from GB-Cr12 material and undergoes heat treatment.

2. Cutting length tolerance is within ±10 meters per 2 millimeters.

3. Cutting operations are characterized by a stable and safe working environment, producing minimal noise.

PLC control system

PLC brand:Delta(Taiwan) PLC, and transducer and touched screen

● Encoder brand:Omron

● Electrical components:Schneider

●Operating language:English and Chinese(or as requested) You can set the orders on this part,changing product length and quantity,it is

really easy to operate,and there are aviation plugs to make it much easier to install the machine while it arrived.

Hydraulic station

● Hydraulic station motor: 5.5 KW

● Hydraulic oil:46# hydraulic oil

● Main components:Include a set of hydraulic tank, a set of

hydraulic oil pump, two hydraulic pipes. And one of electromagnetism valve