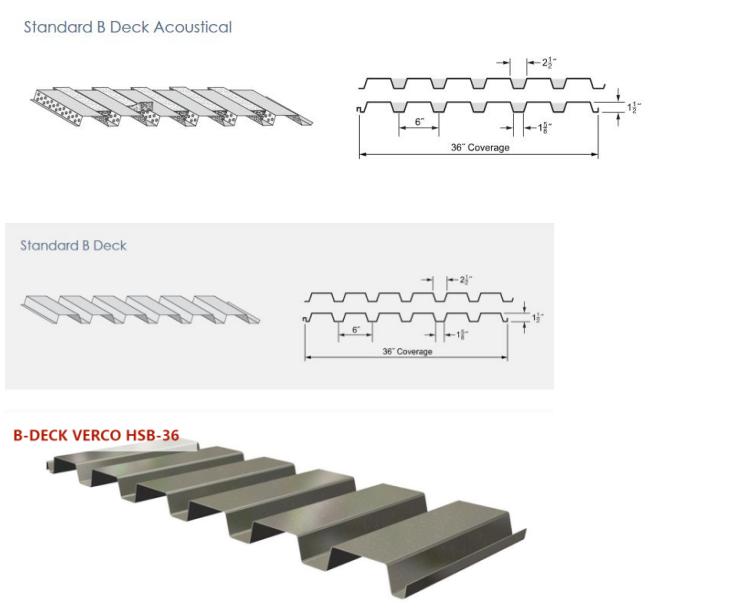

Description:B Deck profiles are 1.5-inch deep structural roof deck that provide both vertical load and diaphragm shear capacity. The wide ribs make the profile an ideal structural substrate to uniformly support roofing systems applied on top of the deck. Type B profiles are typically used for span conditions of 10 feet or less.

Type B Metal Roof Deck Rolling Forming Machine

B-Deck is a 1 ½” deep, wide rib roof deck section that provides a support surface for various types of roofing materials. It is used as a secondary structural member to provide for lateral force distribution to the structure’s vertical force resisting systems. Standard cover width is 36” with either a galvanized finish or prime painted.

What is type B roof deck?

B Deck is by far the most commonly used roof deck for new construction projects. This is due to the fact that B deck is the most efficient 1.5”deep steel roof deck section. Compared to Type A roof decks and Type F roof decks, Type B metal roof decks have the highest strength-to-weight ratio. As with all steel products, the lighter the section, the more economical it will be. And since Type B roof decks can carry higher loads at longer spans than A decks and F decks, the steel supports below the metal deck can be spaced further apart. The result? A larger support spacing results in fewer supports and more savings for the building owner.

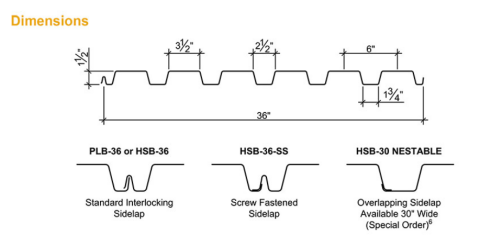

Here is one standard B deck for your reference:

As previously mentioned, Type B deck is the most commonly used roof deck for new construction projects. In comparison to other roof decks such as Type A and Type F, Type B roof decks have a higher strength-to-weight ratio, are more economical, and can carry higher loads at longer spans. Given that steel supports can be spaced further apart with Type B decks, building owners can save money by purchasing less supports

Type B deck is a wide-rib roof deck ideal for a wide range of applications

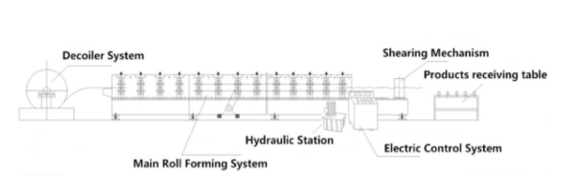

working process of Galvanized Floor decking forming machine

decoiler—shape—shear—receive final product

Type B Metal Roof Deck Rolling Forming Machine

Main technical parameters of B deck roofing decking rolling forming machines:

1) Structure:500H steel welded with 25mm middle plate

2) Main power:30KW Siemens motors

3) Forming stations:36 stations

4) Way of drive:1.0″ double row chain drive

5) Diameter of shaft:80mm

6) Max rolling speed: 12-15m/min

7) Thickness: 0.5-1.5mm galvanized steel or p repainted sheet,G550Mpa

8) Material width:as request

9) Material of roller:polished and coated with chrome, surface with 0.05mm

10) Material of blade mould:Cr12, quenched 58-62℃

11) Way of cutting:hydraulic mould cutting(stop to cut)

12) Length cutting tolerance:+/-1.0mm

13) Hydraulic pressure :16Mpa

14) Hydraulic power:5.5kw

15) Computer Control system:PLC control from Taiwan

16) Omron encoder measure the length ,made in Japan

17) Electrical requirement:380V,50Hz,3Ph

Feeding Device

1.There are 2 rollers at the feeding device, which can be rotated to reduce the friction of the feeding and avoid scratches on the surface of the material.

2.Touch stainless rollers can make the material go into the machine smoothly and prevent the scratch on the material surface.

3. With a hand wheel to adjust the feeding width, making the feeding more accurate.

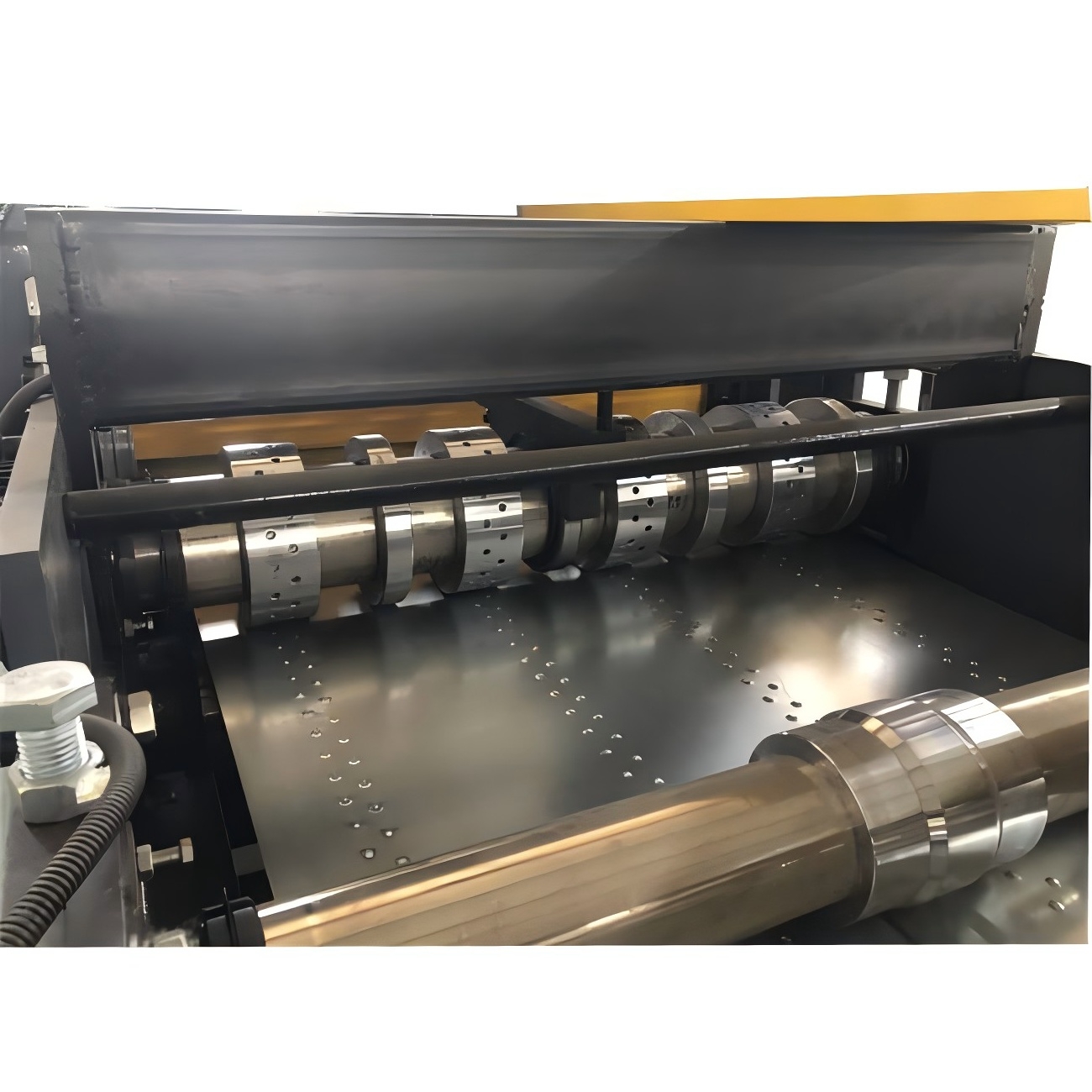

Roll Forming Device

For the shaft and rollers, normally ZHONGTUO uses very strong shaft and big diameter rollers with gear inside , for making higher speed and better rolling effect.

Rollers of Galvanized Floor decking forming machine

Compared with normal rollers, this new model roller quench twice times and prolong heat treatment time.More over, it is equated with 2-3mm chromed seamless spacers.

Shearing part of Galvanized Floor decking forming machine

This Galvanized Floor decking forming machine adopts latest technology.

you can find in following picture: the blade is supported byfour pillars.

Besides,we improve inner side of pillar to minimum friction to prolong its life time 3-5 years.

the blade is set against beaminstead of being fixed on beam directly.

Normally blade is fixed on beam with screws,so that screw holes bear whole pressure and back power.

In this new Galvanized Floor decking forming machine,Beam will share more pressure and back power.

so it will be more stable and its life time will be prolong about 3-5 years.

PLC control system

PLC brand:Delta(Taiwan) PLC, and transducer and touched screen

● Encoder brand:Omron

● Electrical components:Schneider

●Operating language:English and Chinese(or as requested) You can set the orders on this part,changing product length and quantity,it is

really easy to operate,and there are aviation plugs to make it much easier to install the machine while it arrived.

Hydraulic station

● Hydraulic station motor: 5.5 KW

● Hydraulic oil:46# hydraulic oil

● Main components:Include a set of hydraulic tank, a set of

hydraulic oil pump, two hydraulic pipes. And one of electromagnetism valve