Description:Floor Metal Deck Forming Machine is designed for making the metal decking sheets in batch and fully aromatically.

Floor Metal Deck Forming Machine

The Metal Roofing Deck Rolling Machine, an advanced industrial marvel offered by ZTRFM Forming. This cutting-edge device is meticulously designed for the efficient production of high-quality metal roofing decks.The Metal Roofing Deck Rolling Machine boasts state-of-the-art roll forming technology that effortlessly shapes metal sheets into precise and uniform roofing deck profiles. Its automated operations ensure consistent and accurate results, optimizing production efficiency and reducing labor costs.This machine offers versatility in creating various sizes and designs of metal roofing decks, catering to diverse construction needs and project specifications.Its precision engineering and advanced control systems make it an indispensable tool for manufacturers aiming to deliver reliable and durable metal roofing decks for commercial, industrial, and residential buildings.

What is the metal roofing decking ?

Metal roofing decks are available in a variety of types including narrow rib, intermediate rib, wide rib, and deep rib, and are used to support insulation or lightweight concrete and the waterproof membrane of a roof. Our metal roofing deck is used as a foundation for flat steel deck, pitched, and arched roof systems because of their high strength-to-weight ratio of the steel ratio. Metal roof decking products act alone in transferring horizontal and vertical loads into the building frame. These metal roofing deck can be left exposed for open ceiling designs or manufactured with added acoustical perforations. Additionally, metal roofing decks are known to provide a solid work surface for the installation of insulation, weatherproofing, and roofing materials.

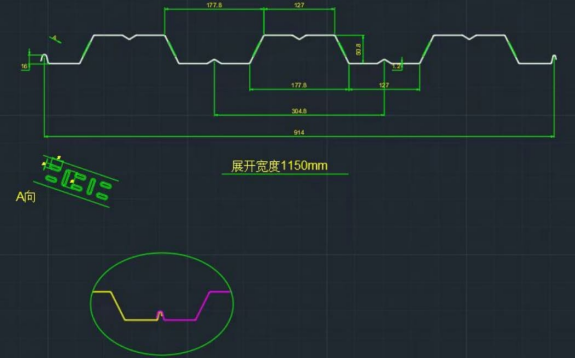

Here is the drawing profile for your reference:

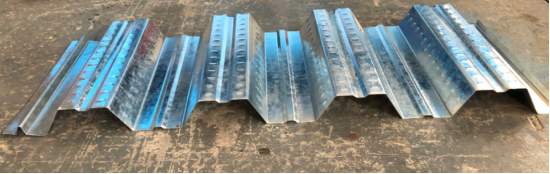

Floor Metal Deck Forming Machine finished products:

Floor Metal Deck Forming Machine

Advantage of Floor Metal Deck Forming Machine:

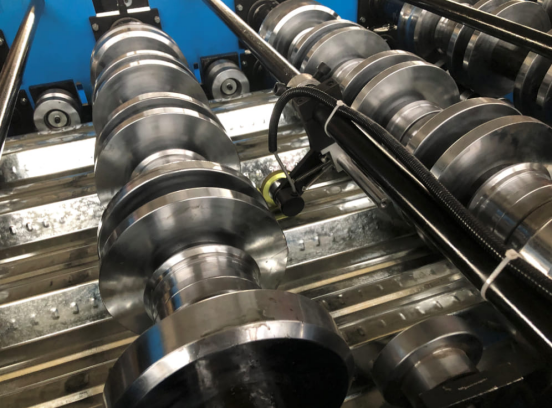

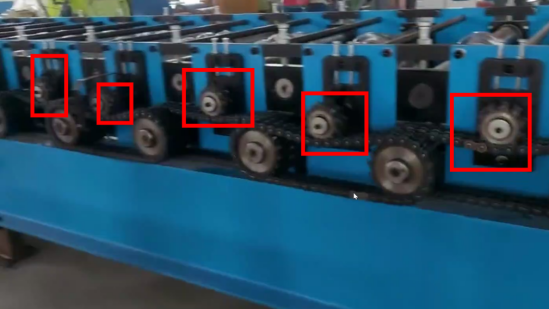

1.Adopt 85-95mm solid shaft and H-shaped steel as the under frame, so that the machine can withstand long-term production without deformation of the machine, thus ensuring long-term machine use life; For the metal embossing rollers, we use the 120mm diameter strong shaft, meanwhile with the keynote design.

2.The rollers are processed by CNC machine tools to ensure the accuracy of the rollers, and thus the accuracy of the final deck. For the metal embossing roller, we design with the brake system and then you can feed the coil easily and make sure the embossing is nice the accurate.

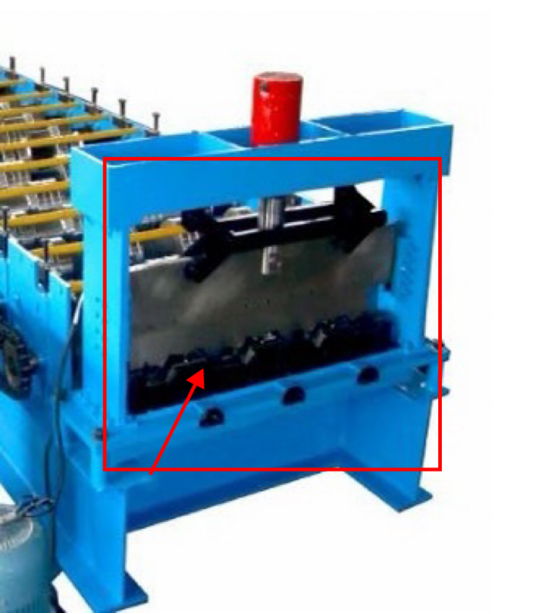

3.Our cut blade frame is stress-relieved to ensure that it is not deformed during long-term production and makes the final product smooth. Frame shearing system is good for the long time to use.

4.The steel decks are flat, high precision within 1mm, and the effective width is controlled within 5mm; When shearing there will be some wasted coil.

5.Use Mitsubishi or Siemens operating system with stable performance, simple operation, as long as the input length and quantity are automatically produced by the machine, and the cutting length tolerance is within ± 2mm

6. Forming speed can reach 8-12 meters per minute

7. The machine weighs about 15-18 tons

8.Our equipment uses double-edged knives. The bottom two blades are the same as the version, and the top one has many saws to ensure that the cutting is not deformed, but there will be a small amount of waste.

9.Combined with the eye end slide section, it is more stable than the guide column structure

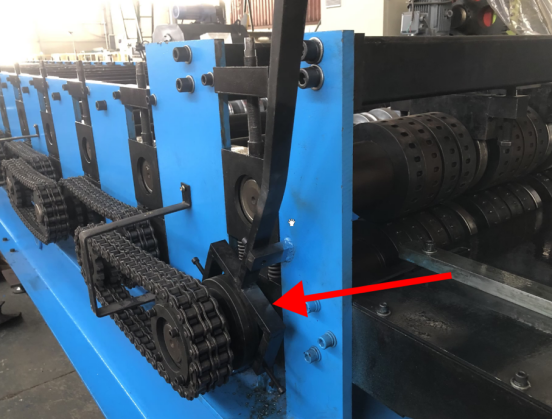

10.There is a gear device on the side, with tensioned left and right, to prevent the chain from loosening due to long-term use

11.The machine is equipped with a clutch device to avoid too fast the main power of the shaft at the feeding port, but the rear wheels have resistance and cause the material to be uneven