Floor Deck Roll Forming Machine

ZTRFM floor deck roll forming machine adapt Siemens control system, easy and efficient to opperate and support romate control. Machine producing speed can reach 25m/min and equiped automatic stacker and hydraulic decoiler very accurate and productive.

Floor deck sheet is a pressed and molded steel plate that supports the concrete on the floor.Increase the friction of the plate, already the contact area between the floor bearing plate and the cementFloor deck sheet panel offen using in steel structure building and can strength the floor.

Let look our machine production:

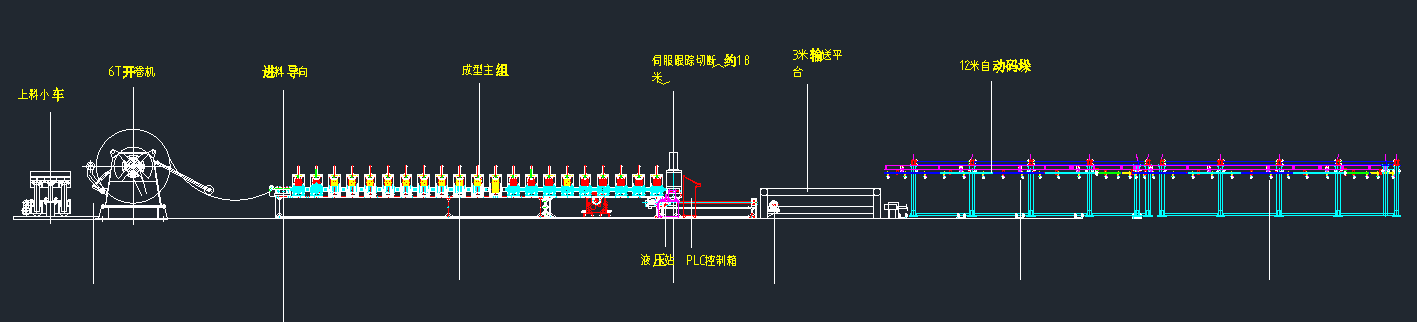

Our machine working flow chat like:

15tons Hydraulic decoiler---Feed materials device---Embossing rollers---Main roll forming machine---Hydraulic cutting system---Convey table---Automatic stacker

Let me introduce our floor deck roll forming machine details:

Part one:15tons hydraulic decoiler

Hydraulic decoiler with loading car motor drive the coils running and can do forward and reverse running as well as do the decoiling with tension.Expand coils range is Φ508-φ600 mm and uncoiling speed can adjust from 0-45m/min, according your production line producing speed, our decoiler can equiped with our main production line.The raw material coils width can reach 1500mm and as customer's need.

Part two:Feed device and embossing rollers

Feed device can protect raw material surface and the embossing roller can embossed materials pattern and the pattern can increase the friction of the plate, already the contact area between the floor bearing plate and the cement.

Part three:Main roll forming part

Main roll forming part has 26 stations rollers(separate rolling design concept, it can release internal stress from the sheets, then the sheet will be in good shape and high precision.) and has 3 motors give power, and machine adopted 2 chains drives type(Keep machine forming more steady and accurate);Our rollers make of Gr15 and chromed treatment (Chrome thickness:0.05 mm), make the rollers surface more smoothly, improve the hardness and prevent abrasion, anti corrosion increase of service life. Our shafts make of high grade 45#steel with heat treatment and Φ95 mm solid. Machine forming speed can reach 25m/min.

Part four:Cutter system

ZTRFM floor deck roll forming machine adapt stop cutting and the cutter materials is Gcr12 quenched treatment.And our cutter oil tube using galvanized steel pipe very durable and beautiful!

Part five: Convey table and automatic stacker

Because machine is high speed forming type , so we equiped with automatic stacker it can organize and flatten productions and convey table put between main forming machine and stacker, can make slow the production speed.